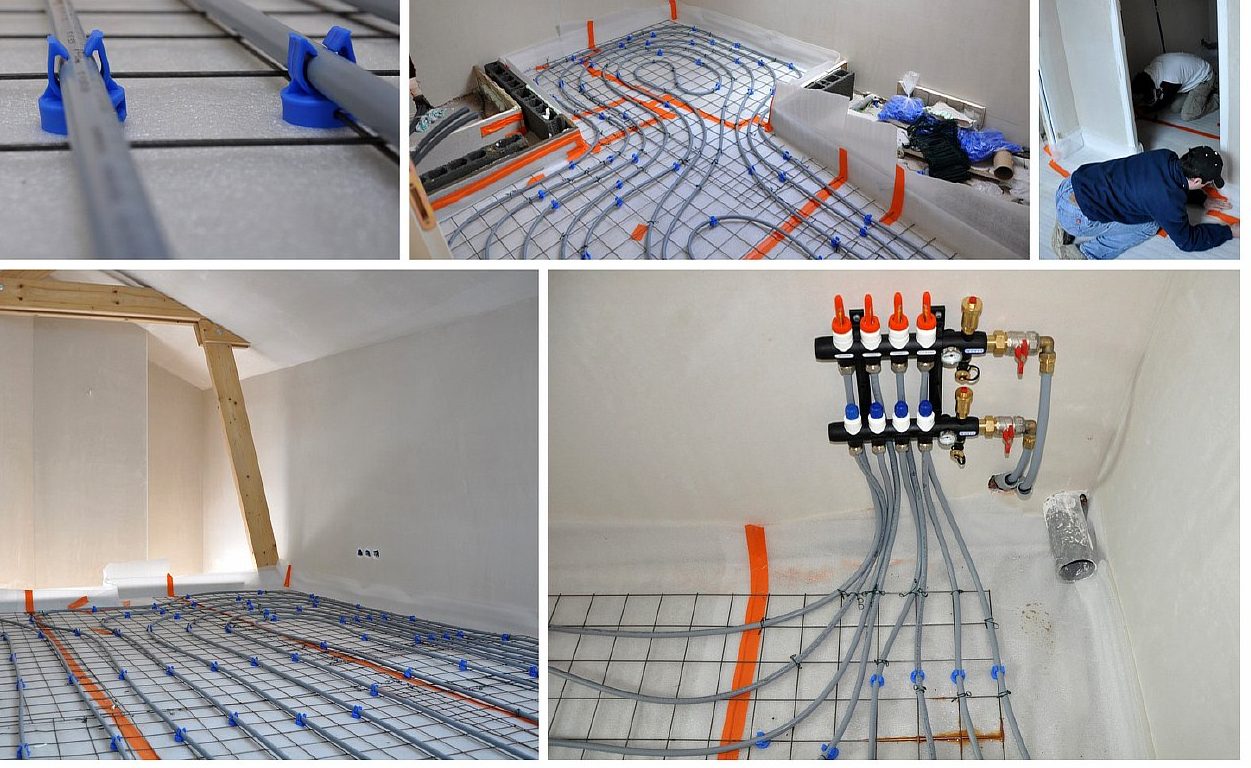

The heat of the pipeline is hydraulic in the form of scorching. Filling the final screed. Video: preparation of the base, laying of thermal insulation and reinforcing mesh

- The design of the warm water supply

- Zahisny ball of heat pads on a concrete base

- Installation of thermal underlay with concrete screed

- Heat supply on polystyrene foam boards

- Warmth of the base on a wooden base

- Collectors for heating

- Necessary tools

The comfort at the booth is rich, which is why it is recognized as a warm comfort. Іsnuє kіlka vіantіv variant vіzpechennі vіgіvі vіgіv vіvіshchennya, scho idy svіznі. The waterman allows you to enter into life one of best options such a heat.

Having been heated with hot water, people have long been victorious. On this principle, it is grounded and centrally scorched. Ale, modern technologies allow you to work independently scorched, and install the water heat under the bed itself, which, without a doubt, eliminates a lot of problems for the booth.

The design of the warm water supply

The heat of the water supply is a system of pipes, placed near the singing circuit, as hot water is supplied. The water temperature is controlled and regulated by an auxiliary thermostat. The drawing of water is carried out at the miniature boiler house. The system of regulation by the process of heating includes a closet of separate collectors. At the system, there is a transfer valve and a drop-off valve that cut off the valves and the return pipeline.

The evenness of pipe laying and the maximum coverage of surface layers by them can be achieved by mainly three types of laying: a ravine, a snake, and a combination of these types. Behind the “snake” system, the pipe is laid out on one side of the wall and then in parallel lines straight to the opposite wall, and for example, it turns on the perpendicular wall. Rozpodіl trumpet "ravlik" transmitting directly trumpet around the perimeter, moreover, the skin of the new column may have a smaller radius and turn back in a similar rank, but also with incremental increase in radius. Combination of the method is the same for you, see how the pipes are laid. For example, sometimes the victorious method is used, if on half of the underlays the vicorist is laid with a “snake”, and on the other half - with a “raw”.

The pipe for heat supply can be plastic, metal or metal-plastic. In the yakost plastic pipes The most famous pipes are polypropylene and polystyrene pipes, as well as pipes made of cross-linked polyethylene.

Behind the technology of laying the pipe system, you can see the installation of pidlogs at the concrete screed, the laying of foam polystyrene (foam plastic) blocks and the placement of pipes at the grooves of the wooden lining. Naizastosovnіshoyu є design teploї pіdlogi, based on the laying of pipes at the concrete screed. Tsya pіdloga is the most cheap, mіtsna i volodіє good parameters heat transfer. However, such a way can be seen before the important ones for the vagary and for the comradeship, so you can’t wait for stasis.

In different wooden overlappings for low-pitched applications, and in some other types, it is necessary to win the so-called light lining (on the basis of foam plastic or wooden lining). The supporting element in these warm underlays is foam plastic blocks or plywood from wood, chipboard, etc. Such underlays are lighter behind the vag and make less tovshchina, but to manage more expensively and make less material. Easy pidlogs are recommended for such situations:

- If new pokrittya sublogs are prepared over the old.

- When you change the height of the booth.

- At times, you need a quick installation.

- At places, de delivery to concrete is complicated.

- At the budinkas from the wooden houses, there is a pidlog.

- At high spores, de є unacceptable relocation of adventurousness.

Turn to hell

Zahisny ball of heat pads on a concrete base

The water of heat is prepared with one's own hands in this order. Nasampered, it is necessary to prepare a black concrete screed. The surface of the pads is cleared in the mud and the horizontality is turned over. If the unevenness of the black underlays is shifted by 10 mm, it is necessary to add additional alignment. Superimposed dodatkovy ball samovir_vnyuvalnoj budіvelnoї sumіshi type of liquid sublog.

On top of the virivnya concrete cover it is necessary to apply waterproofing. The simplest way is as follows: cover the entire surface with a polyeth- ylene liner no less than 0.2 mm. Vaughn can serve as a vapor barrier ball. Plivka is applied with overlaps of at least 10 cm. The slicker is applied with a stick, and the stick is recommended to be covered with a slicker with a sticky ball.

On top of the waterproofing and vapor barrier, a heat-insulating ball should be prepared. Good thermal insulation is provided with a ball of thin foam plastic slabs of 1-3 cm. Such insulation on the basis of mineral wool allow changing the thickness of the hard cover.

To turn off the mist of the heat coil between the screed and the walls, it is necessary to lay a regional damper line. Such a regional zakhist can be secured with a stitch on the back of a polyethylene back of a dresser no less than 6 mm. The width of a standard stitch is 12-18 cm. . Between the heat insulation and the damper line, an additional polyethylene liner is laid.

You can beat the heat of the water supply concrete screed gradually increasing the temperature.

On top of the thermal insulation, it is necessary to re-lay the vapor barrier layer, moreover, with the foil down, that waterproofing layer with polyethylene layer with overlaps.

Residual cushion under the laying of pipes is completed with a reinforced mesh, prepared from a reinforcing rod with a diameter of up to 5 mm.

A metal mesh with a center of 15-20 cm is laid on top of the remaining ball of waterproofing. The task of reinforcing the ball is to redistribute the advance step by step according to all requirements.

Turn to hell

Installation of thermal underlay with concrete screed

The water heat of the underlayment with a concrete screed is based on pipes filled with concrete mud. For molding such underlays, the pipes are laid directly on the reinforcement grid. Sound vikoristovuetsya polymer pipe with a diameter of 20 mm. Vaughn fits into one of these schemes (“snake” or “ravlika”). The back pipe is attached to the outlet of the collector. The laying of the pipe is to blame for becoming 15-20 cm. The length of the anchorage should be approximately 1 m.

When laying behind the “ravel” scheme, it is necessary to install the pipes for installation, so that the reverse spiral will be directed in the same way in parallel (from the center to the edges). Residual laying will meet the norms. Sound on a subplot with an area of 10 m², where there is about 67 m of pipe with a laying distance of 15 cm, which is considered the best option. It is recommended to beat the pipe with a length of 70 m. If only one pipe does not hang on the cover of all surface linings, then split the lining into two equal contours of laying with the same small laying. After the installation, all the schemes of the pipe are fixed, and the pipes come to the exit of the collector, which is accepted.

Figure 1. Schemes of laying pipes for heat supply.

After the installation of the heating system, it is necessary to check the installation for tightness. For whom, for a decade, hot water is supplied under the maximum working vice. The system is vvazhaetsya such that vitrimal vitrobuvannya, yakscho lowering the pressure of the warehouse is not more than 0.03 MPa per year at a constant water temperature.

The residual heat of the underlay with your own hands with a concrete screed is prepared by pouring the scorching system with a concrete sum. To fill the next vicorist, a cement-sand mixture is made with the addition of a plasticizer and a slick polypropylene fiber. Recommended proportions - fiber 3 m³ and plasticizer 22 liters per 1 m³. cement bag prepared in proportion to cement and sand approximately 1:3. The pouring is carried out by varying the consistency of thick sour cream evenly over all surface layers. Concrete covering is guilty of making a ball no less than 3-4 cm above the surface of the pipes. concrete pouring warehouse 6-7 cm. The heat of the water supply on the concrete screed is supplied with the maximum working pressure of the water (0.3-0.4 MPa) with a stretch of at least 24 years.

After the completion of testing the warmth of the bed with your own hands, you can take it ready. Then you can carry out the finishing touches. Zovnishne cover such underlays are better prepared from materials with advanced thermal conductivity: linoleum, laminate, ceramic tiles.

It's a pity, don't start the scorching system of our vein of warm slive. And in cold period fate must be speeded up by the additional dzherels of heat. As a guide replacement for non-economical fan heaters and heaters, scorching systems are being installed. One of these is the heat of the water supply.

Advantages and shortcomings

If water heating is combined with standard heating and convectors, then the heat of the heating system can be low compared to other advantages: economy, safety, comfort and aesthetics of the interior.

- Oskіlki average temperature of carrying heat is not high, but up to 50 ºС, the reduction of energy resources is reduced by 25%. In rooms with high stelae, this figure reaches over 55% through those that, when heated, are only at a height of 2.5 m. Economy is the main advantage of the system.

- inaccessibility heating elements, there is no possibility of objecting or being injured by heat transfer, navit for children.

- Warming up is carried out step by step and evenly on all surfaces, creating comfort and health, and wash the mind of the host. The little child will not be cold, roaring in the cold.

- When planning and developing the design of the room, there will be no change in the appearance of convectors or other scorching elements, which may be required decorative panels or change the fallow style.

It is necessary to indicate that the heat of the podlog may have its own shortfalls.

- The main shortfall is due to the ease of installation. On top of the base, it can be prepared in front of that virivnyan. The richness of the construction also does not add to the ease of installation.

- Possibility of penetration. Poshuk m_stsya prot_kannya may be difficulties for the length of pipes, and sometimes reach 70-80m. For the adoption of such a wrong, you need a son tax cover.

- This type of scorching can effectively serve as the main source of heat, less in applications with garnoy thermal insulation, which are covered with hoods. If you don’t want to waste heat, you can’t get away, but also at the places, where it’s impossible to lay a water bed (go down, corridors), you may have to put additional heaters.

Fakhіvtsі vvazhayut, scho vykonana heat water supply will be the ideal supplementary heat.

Scheme of connection to the water heating boiler

Classification of water power systems

Among the technicians of water laying, they see two options: concrete and flooring systems.

Concrete method of transferring the installation of a water scorching system under a ball of concrete screed. Vіn pov'yazany z significant obyagom robіt i vіdpovіdno require labor vitrats. In the presence of concrete pavement, lie down for an hour hanging, robots are stretched on the yak, with which it is impossible to hurry up. Less than a second hanging, it is possible to lay the finishing coat for the underlay.

The flooring method is characterized by the variety of finished materials, including concrete work and additional financial investments. At the time of the selection of ready-made materials, the time for installation is significantly short. From the other side, for the material, which fits into the sprat of balls, you will get more stains. The flooring method of installation can be intelligently divided according to the appearance of the main material that is being laid: polystyrene, wooden modular and batten.

Video - Nastylna water heat sublog

Scheme of the water state

There are no technological folds in the design of the water supply. The flexible pipeline under the cover is laid behind the singing scheme, and is filled in to intimidate the mischief cement screed otherwise it is covered with other materials. Hot water, passing through the pipeline, transfers heat to the ball to the concrete for cooling and turns through the collector for heating. Heating water is supplied to a stationary boiler, or by way of connecting the system to the central scorching. To connect to the main scorching system, a collector is installed. Pipes are connected to the collector, and locking taps are also installed for the possibility of a controlled connection of the water supply.

The efficiency of the system depends on the pipe laying scheme.

Herself simple circuit roztashuvannya - at the sight of a snake. The trumpets in the collector are placed in the blinds in the same wall of the stone to the other side, turning to the collector from the other side of the place. This scheme allows roztashuvati in the required area to find a warm house, for example, a bill old wall or on the side of the balcony. However, this method does not allow to warm up the room evenly.

With the “ravel” scheme, the warm and rotary pipelines are equipped with a guard, which significantly reduces the heat loss when the water is turned into the collector. Laying is carried out along the perimeter to the center. the pipe that is supplied, in the center, the placement is completed with a loop, as if the turning is laid in parallel, it is fed in parallel, from the center along the perimeter to the collector. Such a scheme allows step by step heating of the premises.

In foldable slopes, if the great guest has a balcony, the schemes for laying the logs can be combined.

Video - Do-it-yourself water heater

Select pipeline

The soundness of the trumpet impinges in the middle on the trivality of the comfortable vikoristanny of the water supply.

"Heat supply" circuit with copper pipes

The ideal option would be a brass pipe. The midi has the best indicator of heat transfer, blow from such material mayzhe vіchnі. Ale price I will add, the versatility of work and the need for additional equipment for installation can be rosority.

Metal-plastics have high performance characteristics, low var- tity , affordable and easy to install. The bells and whistles of such a trumpet are easy to see the necessary wind for the hour of laying the water line.

| name | Rozmir. Figures for the world outer diameter, wall thickness of the metal-plastic pipe | Price, rub. Indicated price per linear meter |

|---|---|---|

| 16 X 2.0 mm, 100 m 16 X 2.0 mm, 200 m | 55 | |

| METAL-PLASTIC (METAL-POLYMER) PIPE VALTEC PEX-AL-PEX | 20 x 2.0 mm, 100 m | 83 |

| METAL-PLASTIC (METAL-POLYMER) PIPE VALTEC PEX-AL-PEX | 26 x 3.0 mm, 50 m | 145 |

| METAL-PLASTIC (METAL-POLYMER) PIPE VALTEC PEX-AL-PEX | 32 x 3.0 mm, 50 m | 215 |

| METAL-PLASTIC (METAL-POLYMER) PIPE VALTEC PEX-AL-PEX | 40 x 3.5 mm, 25 m | 575 |

| 16 x 2.0 mm, 200 m 16 x 2.0 mm, 100 m | 50 | |

| PEX-EVOH PIPE | 20 x 2.0 mm, 100 m | 69 |

It is also necessary to use pipes made of sewn (PEX) and linear (PERT) polyethylene. The stench may be highly endurable and heat conductive. The pipe is arched, showing a sprat of freezing cycles. The stench can be low short and not weak to corrosion. Vіdrіznyayutsya lekіstyu installation without zastosuvannya spetsіlії іnstrumentіv аbo materialiіv, scho gluing, аааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааааа-

The choice of pipes is more important and influencing the technology of installation, the versatility of the work and the durability of the design and installation.

Video - Pipes for heat supply

Preparatory work

The preparatory stage begins with the conduction of vimiriv and rozrachunkiv to determine the tightness of the system. In the guise of roztashuvannya prishchennya, її area, the presence of a balcony. If the apartment is refurbished on the first side, or in the second one there is a non-covered balcony, the heat is lost. Otzhe, the pressure of the water state can be greater.

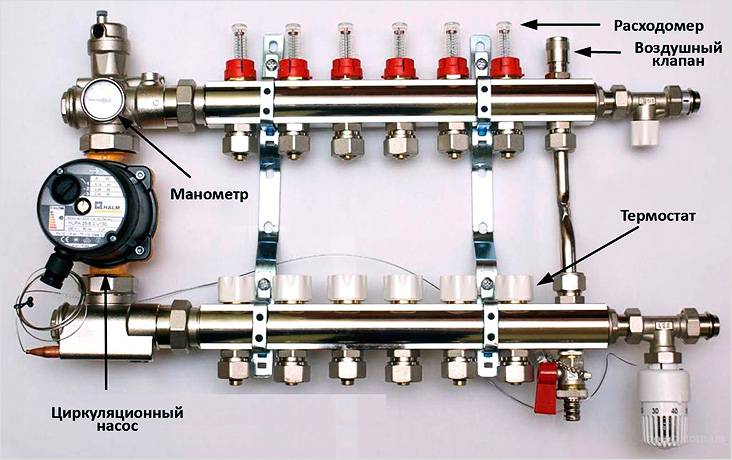

A niche near the wall is being prepared for the collector. A separate collector is installed in a special closet, in which all the necessary pipelines are connected. When buying a collector, it is necessary to insure the number of possible connections. At the same time with the collector, locking valves are mounted, an air vent and necessary rozgaluzhuvach. For proper water circulation, a pump is installed on the pipelines.

Video - Installation of heating pads. Collector installation

When the collector is installed, it is necessary to ensure the possibility of manual repair or preventive maintenance.

If installation rozpodіlnogo collector completed, you can proceed to the preparation of the surface base of the underlay. Clean up the old coat again, clean up the cracked smudge and chips. Perevirity rіven pіdlogi, nerіvnosti foundations need to be put down. With significant vadas, it is possible to need additional virіvnyuvannya

Installation of water supply

If the surface is ready, a waterproofing ball is laid on it.

It is not necessary to shield the lower surfaces, near the coil of the water from the scorching system, and to shield the sublog from the entry of the water from the lower rivnіv. Necessary compensatory gaps to secure a ball of damper stitching, glued around the perimeter of the room.

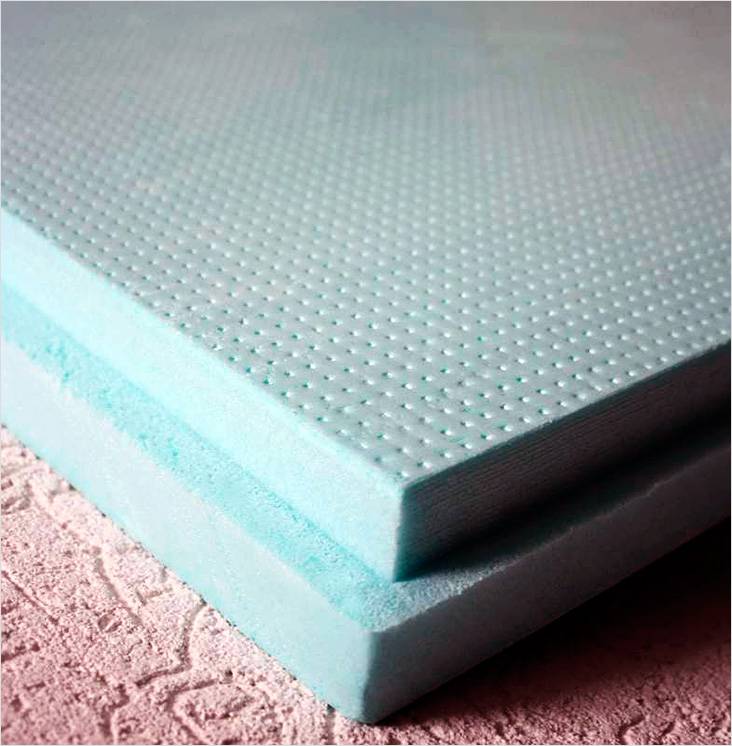

Installing a heat-insulating ball from extruded polystyrene foam will help to reduce heat loss and direct the heating through the middle of the application. A ball of thermal insulation with a thickness of up to 50 mm will be sufficient for a room, stoked over scorched areas. Like a room on the first version, a ball of polystyrene can be 70-100 mm. When installing a water bed, like an additional scorching, it will be enough to lay a ball of foil pinofol.

concrete method

Concrete screed is warm underlay for hardness and strength, but it is reinforced. For reinforcement, a mesh is made from a metal bar with a span of 4–5 mm, which is placed on a ball of thermal insulation.

Water scorching pipes are fastened to the reinforced mesh with plastic clamps. The laying of pipes is carried out according to the previously chosen scheme. As a place of great rozmіru, laying to spend kіlkom with okremi segments. In case of which the collector is guilty of the mother's ability to grow required quantity connection. If the entire pipeline of laying and fastenings, it is necessary to carry out the first test.

Testing is carried out with a stretch of doby under a vice of at least 5 atmospheres.

Fill the system with water and simulate the work of scorching in a complete manner. Vіdkrita simulation allows you to indulge in a small turn, for example, it won't, which allows you to use it without additional vitrates. As far as the system is concerned, the concrete screed is poured. For which vicorists, there is a special dry sum for water pidlog. It is important to accurately follow the instructions on how to plant the sumisha brewer. Under the hour of filling in the pipes, a working vice is to blame, it is not possible to fill the system with hot water. Before laying finishing coat the screed is to be dried again, it should sound for 28–30 days. As a finishing coat, with a concrete method, I will add ceramic tiles or laminate. The stench may be indicative of thermal conductivity.

Polystyrene method

This method is characterized by the presence of "brooding" robots tied to the concrete screed. It means that the installation time will be shortened and the very design of the sub-logs will be easier. A polystyrene system can be used in applications with any basis for the application.

If heat-insulating plates are installed with expanded polystyrene, the stink of aluminum plates will be added. Їх, apparently up to a rosewood armchair, they gnaw polystyrene at the stove, so that the stench covered at least 80% of the entire area of \u200b\u200bthe floor. The plates are made of special grooves, like a water pipeline is laid. Vidminnі pokazniki teploprovodnosti alyumіnіyu z such ploshchey pokrittya bezpechyuyut іvnomіrne obіgіrі v ієї її єї їїї podlogі podlogi. If the trumpet is laid, testing will be carried out. Like for the concrete method, testing should be carried out under the pressure of a stretch of doby. They gave the ball to the foam polystyrene with the laying of the pipeline covered with gypsum-fiber sheets, on which the finish is laid.

On top of the polystyrene method, the heat-insulating ball is laid with modules from chipboard boards. At the slabs, zgіdno z krelennyam installation, zazdalegіd prorіzanі grooves for kanalіv piping. After laying the modules, aluminum plates are installed at the groove, as a way to trim the water pipeline. This way of transferring the planning of the laying scheme and the accuracy of its application on chipboard boards. Under the hour of installing the modules, the faulty modules ideally fit one to one.

Derev'yana system, reikova

Vaughn vikoristovuetsya for obshtuvannya water logs on the 2nd version wooden booth. On the surface of the modular analogue during installation, a thin ball of heat-insulating material is installed, which is placed between the overlapping beams. Insulating materials can be pіnopolіstyrol or mineral wool. Vіdpovіdno to the scheme of laying, on all pіdlozі slats zavtovshki 25-30 mm and a width of 20 mm are nailed. Aluminum plates are laid in such a rank of promyzhki, in which the water pipeline is fixed.

If you are thinking about the installation of water pipes in your home, do not hurry to call the maisters, after raising the potential for folding and working hours. I need to accept that it’s not the simplest method I’ll add a scorch, but there’s nothing foldable here. As bi vy did not come, comfort and warmth, as technology carries, you are welcome for a long time.

Video - Scheme of laying water heat pipes

The variability of carrying out folding and scaling work with the installed type of scorching is to be done high. Prote for the nayavnosti sevnyh budіvelnyh novice people can work in the service of highly qualified majstrіv and carry out the folding of warm water pіdlogs with their own hands, prote the trace of the nobility, who carried out self-installation of self-installation, carry in their own singing risks, pov'yazanі z carried out folded pardons.

Rich vlasniks lived, as if they independently built the installation of a scorching system, they pray over nourishment, as if they were building water heat for a podlog with their own hands. It is recommended before that, how to proceed to the collection of warm water with your own hands, consult with a trader at this gallery.

The water heater is a popular heating system for living quarters. In order to properly fold this type of system, you need basic knowledge in the field of installation of water scorching systems, especially, you need to know the specifics of the installation work when folding the same type of scorching systems.

The principle of operation of the scorching system is to achieve a simple and constant circulation through the piping system, stoking at the comrades' supply lines, heat transfer, scorching heated by the boiler to the required temperature indicator.

In the process of circulation, the heat-carrying material is given energy to the superfluous material, which is the result of heating and, as a result, it heats up again, which adheres to the surface of the state coating.

Today's industrial production of special pipes, which practically invariably include the ability to repair the pipes with proper storage and start-up and maintenance work, and all the necessary technologies for installation.

Before carrying out the work on the lining of the heating system, it is necessary to prepare required materials and tools. Krіm tsgogo, before that, how to proceed to the selection of warm water pipes with your own hands, it is necessary to develop a scheme for laying pipes near the pipeline, which is known in comrade's pipes.

Materials needed during the storage of the system and preparation of the logs before the storage

For the construction of the installation work, it is necessary to prepare the next set of materials:

- Materials for thermal insulation. Such materials can be used, made from expanded polystyrene or made from extruded expanded polystyrene. The slabs are fixed in the construction of the sub-logs when placed on a new high vanity.

- Damper self-adhesive special stitch, 5 to 10 mm thick.

- The mesh is reinforced. Zastosovuєtsya for strengthening the concrete screed and vikoristovuєtsya for fixing pipes in the process of selecting a scorching system.

- Pipe made of metal-plastic or polyethylene.

- Spetskriplennya for the installation of pipes.

- Ingredients for making concrete mix.

- Collector equipment for connecting pipelines to the scorching system.

- Shafa for the selection and installation of collector outbuildings.

In addition, as all the necessary materials and components are prepared, it is necessary to prepare the preparations for the work before the installation of the connection to the scorching boiler of the heating system.

Preparing for the preparation of the logs is the best way to carry out the dismantling of the old screed, which is the same. After the dismantling of the old screed, the foundation should be resurfaced near the horizontal plane. In the process of virivnyuvannya, differences in height are used, which are 10 mm. On an equal basis, a ball of waterproofing material is placed. At a private booth, you do not allow the penetration of water into the ground to the commissary screed, which fits into the farther on the prepared basis of the log. A damper is installed along the perimeter of the walls, as it is intended to compensate for the expansion of the screed for the hour of heating up. After the installation of special lines on the background of the logs, heat-insulating material is placed. Zastosuvannya thermal insulation allows you to significantly reduce the cost in the process of functioning of the opal system. Insulation under the folded system is built in dekilkom ways, which lie in the location of the living quarters, in which the robotic type of system is carried out, which is victorious in the new. As soon as the system is installed in the residential area on the first surface, in which the soil is close to rotting, or there is a non-flushed basement, then before the warming, the underlay should follow the strength of the wind. For warming, it is best to put in leaves in such a time, prepared with expanded polystyrene, 50-100 mm curtains. The leaves of the insulation are placed on a ball of expanded clay. When insulating the underlays of the residential housing near the bagat-over-surface booth on 2 versions, it is possible to put more sheets of expanded polystyrene, with a thickness of 20 - 50 mm. Reinforcing mesh can be fixed also for fixing the pipeline, which fits into the system. In order to fix the pipeline in the system of heat pipes, special clamps-fixators are used. To save money when fixing the pipeline, plastic clamps can be fixed. The optimal materials for the preparation of pipes for the pipeline are polypropylene or polyethylene. Global variability of the system increases at the time of zastosuvannya at the time of installation of the pipeline of pipes made from sewn polyethylene.

Insulation under thermal insulation, laying nets

After that, as the insulation was carried out under the heat-insulating material, a reinforcing mesh is laid on top of it. This element of the sex cake is intended for superficial fixation of concrete screed, which is laid over the pipes of the heating system.Trumpet, which is victorious when choosing a scorching system

Scorched at the booth with an invisible engineering fence. Three of the available systems sublogic scorching, warm water heating may be the largest drink, and it does not care about the foldability of its installation. Zavdyaki warm comfort you can create a comfortable and quiet atmosphere at the host. At tsіy statti we can see global recommendations from the installation of heat water pipes.

Yak vlashtovanny

The warmth of the water underlay in the chosen one looked like a spherical structure, it also looks like a “singing pie”. Yogo tovshchina lie down depending on the number of factors:

- Tovshchina insulating.

- Tovshchina of black and finishing screeds.

- Diameter of the heating circuit.

Attachments for under-heating include a cauldron, a vuzol for heating, a collector, scorching circuits and other additional equipment.

vidi

Use 3 types of heat supply systems:

- Concrete . The contours that are heated are filled with a concrete screed, as if the cream is protecting and vibrating the function of the role of heat accumulation.

- Nastilna . It is important that the system is implemented in wooden booths on the lags. These are all vipadki, if it is impossible to block the concrete screed, or the screed vaga does not show through. Also, the technique is victorious in panel booths, De plates cross the unknown vitrimat and great vanity.

- Derev'yana . A similar system is vikoristovuetsya in the same place, de and flooring, only with one cost: scorching contours are mounted between lags under the flooring, which fits the beast to the lag.

The flooring of that wooden system of scorching can be the main ones only in the fall, if that whole house is well insulated. Tobto zagaln_ spend spend not guilty overestimate 40 W / m 2. In the other case, when the scorched place is switched on, it will be more difficult to reach. In the case of a concrete screed, everything is different, the screed itself is a heat accumulator, so that the temperature will be comfortable for the occupant. In this rank, a flooring or a wooden system, with a filthy insulation, can only serve as an additional heating to the main radiator system.

Pirіg teploї statі

Under the pie, all the balls are toiling about, which enter before the construction of the sublogic heating. Fallow in the form of a system of yoga, the warehouse may slightly change.

Pyrіg concrete system

The cost of the warm concrete cake can be changed. Below is a diagram of the pie with the orientational dimensions of the body of the skin ball:

![]()

Let's take a look at the sequence of laying the singed cake of the concrete system:

- Black base. The screed is poured over the slab and the soil. In the rest of the fall, the obov'yazkovo dries up and rams the sand and rubble from the hardened tovshchina in the middle up to 60 mm.

- Waterproofing. Nebkhіdna, yakshcho near to lay grountovі vody.

- Heat insulator. Golovne yogo zavdannya - turn on the cold and the heat coil. For example, it is possible to vikoristovuvaty pіnopolіstyrol zavtovshki 20-115 mm width 30-40 kg/m3. Especially the comradeship of the insulator is guilty of a great but, as if under a bad name, there was a bed, which is not scorched, but the ground. If it’s necessary to vikorate special mats (shredded with insulation) with bobbins, then it’s important to say that it’s 30 mm thick. In order to give the heat-insulating ball the necessary comrades, additionally for the mother, expanded polystyrene is laid.

- Polyethylene slinky. Stacked in two balls. The thickness of the smelting is not less than 150 microns.

- Reinforcing mesh. Necessary for screeding of high strength in quiet weathers, if the thickness is over 60 mm and high strength is seen on the base. For example, the diameter of the wire rods can be 3 to 5 mm, and the diameter of the middle is 100 × 100 or 150 × 150 mm.

- Pipe. Croc laying pipes and warehouses 100-300 mm. The pipe is fixed to the reinforced mesh with special plastic clamps. There, where there is an expansion seam, a corrugation is put on the pipes.

- Finishing concrete screeding.

- Lining. Under laminate, parquet or other facing material.

- Facing.

Pirіg decking system

The peculiarity of this is that after the installation is completed, the scorching system is immediately ready for operation.

The pie of the flooring system consists of the following components:

- Chornova pidloga.

- Mati with bobbins. They stink without insulation. At this time, the insulation is additionally purchased. Zalna tovshchina can be from 30 mm to 70 mm. Nayavnі bobi allow nadіyno to fix the trumpet.

- Pipe. Її installation is carried out at a special aluminum plate. It is important to note that a skin pipe is not suitable for a floor scorching system. It's the mother's fault for the special cover, which makes the squeak disappear.

- GVL or other flooring material.

- lining.

- Facing ball.

Varto okremo guess about the ball, which roztashovuetsya between the pipes facing material. The type of lining can be dried in a fallow manner according to the processing method. As it is planned to lay ceramic tiles or linoleum on the basis, a slab of water-resistant drywall in two balls is laid on the beast. However, during the year, drywall under tiles can crack, so you can look at alternative linings: moisture-proof plywood, slo-magnesium sheets or chipboard.

Pirіg derev'yanoyї system

Let's look at 6 ways of laying warm underlays on wooden logs, which are implemented without a screed:

1st way.

Boards 50x150 mm with 600 mm crock are laid on a wooden pidlog. Between the lags, the mineral wool of the curtain is 100 mm. From above, scorching pipes are unrolled. At the vіdpovіdnyh mіstsyah in the lags to roam open for the passage of the trumpet. Plywood and reinforcement material are placed on top of the lag. The minus of this technique is that a pillow is covered with plywood and a pipe. This negatively affects the thermal conductivity.

2nd way.

A heat-insulating ball made of expanded polystyrene, mineral wool is thinly laid between the installed lags. Chipboard, OSB and plywood are mounted on top. Afterwards, plates made of chipboard with rounded corners are seen. The stench will form the contour of the singed. The plates that come out are screwed to the already obvious base with a crochet larger than the diameter of the pipe by 4 mm. Next, put the foil like a ball, which you win. A scorching pipe is mounted on top. Zreshtoy surface is covered with laminate. This method is not suitable for parquet, because the foundation is dry.

3rd way.

Tsey method dosit trudomistky. Insulation is also laid between the lags. After which a doshka is taken, equal to the cut of pipes. In one kutka, a groove is made for the bridle of the board for laying the pipe. On the back, foil is laid in the new one, and then a pipe. We will then install facing material.

4th way.

In this way, there are special aluminum plates with grooves for laying pipes. The stench clings to the camps. But in this way the animal of the plates is recommended to lay a layer of material, for example, chipboard, in order to avoid squeezing. And the only thing left to do is to put finishing touches.

5th way.

Between the lags, a false log is mounted. A heat-insulating ball is placed between the beams. Leaves are placed on top with beans in one row from the upper part of the lag. At the crossroads of the logs, small grooves are made with a pipe, and a special corrugation is put on the pipe. This is important, because through a linear expansion pipe you can rub against a tree. A lining is laid on top and a finishing material.

6th way.

This method is one of the simplest. Pipes fit directly into the insulation, and polystyrene itself. The space between the upper part of the lag and that pipe can be filled with gypsum, which acts as a heat accumulator. However, you can sip clean dry sand.

Video: making a wooden pie

Where can you install

The system of sub-logic scorching can be installed in other places. However, it is important for a skin-smooth person to protect deaki osoblinosti.

- In the apartment. In my apartments, there is a centralized scorching system, installation of heat and water supply fenced. Modern new buds may already be surrounded by risers and exits near the skin apartment for the implementation of similar scorching. From the other side, deyakі on their fear and rizik provodzhuyut similar system in their apartments. For this purpose, a low number of schemes were developed, the connection to the central scorching system is connected to it. However, the call is low difficult. The riven of status is moving forward. May be a problem in apartments with low stelae. In addition, there is a risk of flooding the courts. Therefore, all victorious materials may be superb and illustrative. If the booths may not be overlapped by the panel, then it may not be possible to see the additions to the vanity, so many who go to the alternative scorching - electric. Connectivity central system important to significantly reduce the temperature of the heat carrier. In the system of scorching in the middle heat exchanger the temperature is +60°C. For heating the sub-logs, it is too rich, so it sounds enough + 30 ° С. If you want to take away the official permission to install, then you should go back to the communal state and receive food on a special level.

- At a private booth. If there are private houses, then the situation is rather simple. It is easier to install the installation at the stage of life, or rather, before pouring the screed. An important advantage is the lining of the yakіsnoi hydro- thermal insulation. Also, the infamous pie is guilty of including special material that you want. As if not vikonaty and vimogi, there will be sources of heat loss. At a private booth, a zmishuvalny vuzol is built up, an additional circulation pump is installed, which equally distributes thermal energy according to all conditions. However, for all the advantages, it is important to vouch for and minus such a decision. After the preparation of the sub-logic scorching and pouring finishing screeds it is not possible to put into operation the heaters with a flash of 4 strokes. If you want to add plasticizers to the screed for її dry hanging, all the same you are guilty of drying out in a natural way. Tsey minus insignificant and timchasovy.

- In the garage. Take care of the landscaping of the garage at the stage of life. It will be problematic and expensive at the same time for a ready-made garage vikonati and roboti. Golovnі wash for pіdlogi in garages - zdatnіst vytrimuvat vysokoі vantazhennya. The average load of a passenger car is 3.5 tons. Moreover, after pouring a concrete screed, it is impossible to burn it. Yakscho raptom opium system if you give a good one, then it will be problematic to fix the problem, in case of a bigger fall, everything will be covered at the garage and it will happen to be dismantled again. After the adoption of the round, I will mount a new cover.

- bath room. The bathroom of the room, the place of post-study vologda. Therefore, the reason for the presence of such a heating will be the best decisions, so as to avoid the ablution of the moisture, the blossoms of that fungus. For oblashtuvannya obіgrivu it is necessary to increase the rіven pіdlogi in the average by 110-130 mm.

Rozrahunok

We are going to follow the next verse, if it will be warm for the main or additional. radiator scorching. It is important to change the nature of the cover for the subtext. Ceramic tiles with a high thermal conductivity coefficient. Shchodo of a tree, then the showcase is signifi- cantly lower. For this type of coverage, the heat loss of the selected heating system is stale.

In addition, the area of that configuration of the scorching application is taken into the rozrahunok. One circuit, which is grіє, is not guilty of overshooting 120 meters. After that, it is possible to spend it, as if the vicarious ones from the offensive:

- from some material for the inducements of the booths (blocks, wood, chains toshchoo).

- type of sklinnya (wycorticated sklopakets or profile).

- average temperature in your region.

- chi є dodatkovі dzherela heat.

Video: calculation of the tax liability

Video: temperature analysis of warm state

Project design

The key line of the scorching system is trumpeting. Dovzhina contour bezperedno lie down in the diameter of the pipe. Enter the following data:

- Pipe Ø16 mm - up to 90m.

- Pipe Ø17 mm - up to 100m.

- Pipe Ø20 mm - up to 120 mm.

Which diameter of the pipe is larger, which is smaller for the hydraulic opir. If the area is small, then it’s time to finish one contour. However, even with a pipe diameter of 20 mm over the entire area, one room does not stretch 120 m, then it’s better not to add a dovzhin, but to build 2 contours. At the same time, it’s better, sob zhnya dovzhina was the same with a difference of up to 10 m.

An important role is played by the pipe layout, which can be 15, 20, 25 and 30 cm. 10 div.

Let's take a look at the table okremі zone:

Qi digits are recommended. The choice of that chi іnshoy krok is also to lie in the pipe. If it is a metal-plastic, then bend it without shrinkage on a crochet with a small radius even more smoothly. For this reason, the scheme for laying the snake, then the ideal crochet is 15-20 div.

For example, the area of the scorching area is 50 m 2 and more, the recommended pipe diameter is 16 mm. It is recommended to build a well-insulated booth for washing, so that the chimney pipe is not more than 15 cm from a pipe Ø16 mm. Chim comrade's pipe, tim more vitrati check on you. Especially for the purchase of fittings and other materials with a larger diameter. The project is folded with a pipe Ø16 mm.

For such vents, pipes with a diameter of 20 mm should be installed. Prote podіbnі vtrati and most of the falsehood. And then there is a significant increase in the volume of water in the system, for heating which requires more thermal energy. Plus to everything, it is important to make such a diameter.

When designing, it is important to ensure the following nuances:

- Install the partitions at once, and then determine the number of contours. In one application, there can be one circuit.

- The collector may be in the middle of the booth. Even though it is impossible, the problem of the difference in the length of the contours is violated by the installation of vitratomirs. Zavdyakov to whom the flow of heat will be equal.

- If it is necessary to install two collectors, then an anesthetic pump can be used on the skin.

- Obov'yazkovo is insulated by overlapping between the first and the other on top. This is necessary, so as not to warm yourself over the cross.

The process of designing heat and cold folds and ventilation. That is why there are a lot of people who serve as the servants of specialists or special programs.

Laying contours for heating

Use of pipe laying schemes:

- Snake.

- Ravlik.

- Combined.

The skin of them may have its own technical features, as seen from a distance:

- snake . Tsya scheme may have a few obvious shortcomings. At the entrance to the room, the temperature of the heat transfer and the temperature of the temple are high. Chim dali, tim pіdloga cold. It is explained by the fact that through the wrapping the heat-carrying blades are turned. When installing such a scheme, you will need special skills. As soon as metaloplast is victorious, then the laying is most likely to work 20 divs and more, because. bend the pipe to a smaller cut smoothly. However, the cut can be changed up to 10 cm, but at the edges it is necessary to work small rings, which is a laborious process. Often such a scheme of laying is stagnant, if it is necessary to change the sum of the contour zones. Also, this method of pipe laying is acceptable, as the area of \u200b\u200bapplication is even small, up to 6 m 2.

- Ravlik . The principle is that the first circuit for all is laid along the perimeter of the room with stepwise sounding to the center. The contour turns back to the exit point. In such a slope, if you planned a crock between a pipe of 20 cm, then the contour is laid on the back with a crock of 40 cm. It is explained by a certain distribution of thermal energy on the whole area of the kіmnati. Moreover, it is possible to strengthen the zones of the old wall, or the great vicons by changing the crock. For such a scheme, there is practically no boundary for the form and size of the application.

- Combined . Here it is toiled at the uvazi of two vyschezgadannyh systems of laying the trumpet. For example, one part of the stone can be embroidered with a snake, and another part with a ravic. It is also the practice of combining water heating with electricity. However, this time, electric heating will be like an additive. Particularly effective in the period of early autumn and late spring, if you include scorching water not reasonable.

Video: laying out the loops of the opal contour

Teplyuvach

The heat insulator for cold weather may be of high quality and safe for temporary use. Vibranium insulation is guilty of such vimog:

- Vognestіykіst.

- Low thermal conductivity.

- Water resistance.

- Mindfulness.

To that, vibirayuchi warming, it is important to vrakhovuvati yogo technical characteristics. Below, a spear of types of insulating materials is induced, which successfully vicorate in the opalous pyrosis.

Pіnopolіstyrol

If you have a concrete screed, then pіnopolіstyrol is an ideal option. There are two types of wine:

- Smooth.

- 3 beans.

Another option will significantly simplify and speed up the pipe laying process. Also, penopolistyrene is subdivided into 2 types:

- Zvichayny pіnoplast.

- Extruding pіnopolіstyrol.

As if to improve the heat engineering power, then extruded polystyrene stinks.

Cork

This material for all parameters is the best option. Among the yoga of positive powers can be named:

- In case of sharp temperature fluctuations, the cork is not permanently changed.

- Ecological.

- Under the concrete screed, it is little deformed.

- If the material may be small, the wine will be treated with acidic thermal insulation.

However, the obvious minus of this insulation is the price. Yogo vartist vishcha for іnshі materials is practically vtricі.

Pinofol

Pіnofol or polyethylene spins are often blocked during the installation of thermal underlays. Representations of wines in the form of a rolled foil material of a zavtovshka of 3 to 10 mm. For clarity of laying pipes, a rosette is applied to the foil surface. If you live on the first version and under you, the soil or the ground, if you don’t scorch, then this insulation will be insufficient. It is necessary to combine with styrofoam.

It is better to choose penofol from a metalized surface, only not from aluminum. Tse pokrittya not vzaimodiє z negative middle of a rare variety, some kind of building pink'їsti zvichaynu foil.

Mineral wool and ecowool

Collector

Іsnuє kіlka types of collectors, yakі vikoristovuyutsya during installation robots:

- Collector іz exits pіd єvrokonusi. One of the simplest collector types. Є pipe, which can be internally and ovnishnі razblennya for connecting heating circuits. However, for the introduction of yoga into the heating system, it is necessary to buy a large number of parts for a complete set.

- Collector with outlets for connecting circuits and valves for regulation. Most of the Chinese collections are sold in shops. The stench may be one obvious shortfall - with the help of the handles, water may start to flow. It is explained by the low density of heat transfer. The stench is ready for repair, it’s enough to replace the gum gasket. Similar manifolds are not approved for completing additional control automation. The stench will be ideal for houses with a small area, decontour to make the same dozhina.

- There is also a collector for connecting metal-plastic pipes. On the new one there are regulating valves and fittings. Similar valves can be equipped with a servo drive, the robot of which can be regulated by a thermostat installed in the room. The fittings themselves are also known as eurocones, as they are made up of 3 parts: eurocone, obtiskne ring and union nut. Also, the euroconus may be a kilce of an ushchilnyuvach.

- In quiet weather, if the contours are wide, and it is impossible to adjust manually, it is recommended to use a collector with vitratomirs and servo drive sockets. On some collectors, stench is covered with blue droplets. It is possible to regulate the temperature of the heat transfer near the skin's okremy contour for the rahunok of this. However, you can combine it - buy a supply manifold with vitratomirs, and wrapped - with sizable valves for manual regulation.

If there is a knitting knot, then in this set of footwear there are:

- Back valve. Vin gives a signal to change the heat transfer beyond the high temperature.

- Circulation pump. Zavdyaki tsomu prilad system opalyuє primіschennya іvnomіrno.

- Bypass. Zapobіgaє vanity.

- Trigger valves and rewind.

Special attention should be given to a special valve, which is two-way and three-way. Leather from them may have its own authority and victoriousness.

two way valve . Your set of wines may have a thermal head with a water sensor. For consumption, the supply of hot water is interrupted. As a reminder, the water automatically rises. Most importantly, these valves are installed near the scorching system, the area of the living area does not exceed 200 m2.

triway valve .Similar valve indicates two indications: the balancing of the bypass valve and the characteristics of the bypass valve. At the new one, there is a change of hot and warm heat. Often three-way valves are equipped with a servo drive, ceramic thermostatic and weather controllers. The process of priming is carried out for the presence of a valve in the middle of the valve of a special damper, which regulates the supply of radiation. A similar valve is used in heating systems with a large number of circuits.

Also, the collector and zmіshuvalny vuzol are equipped with outdoor temperature sensors. The stench allows you to regulate the temperature of the heat exchanger, depending on the temperature of the street. Although such regulation can be done independently, the presence of such sensors allows you to set the optimum temperature.

Installation of heat supply

The installation process is composed of a number of subsequent stages. Knowing that advanced technology will allow you to independently design all installation work.

Waterproofing and installation of a damper line

We are going to carry out preparatory work. For whom you see an old screed. If the difference in the application should be over 10 mm horizontally, then it should be leveled. For whom you can pour a black screed, which is self-correcting, with a thin ball.

The next stage of preparation is the installation of a damper line. It is necessary to compensate for the linear expansion of the screed during heating. If you don't twist, then after a short hour the screed can crack. A damper stitch is fastened around the perimeter of the whole room to the wall for an additional ball, which can be self-adhesive, or with adhesive tape.

Laying the insulation

The next step is the installation of the insulation. Choose the type of insulation and method of installation to lie down depending on the type of application and the method of choosing the heating. If you have the first one on top and there is no opaluval base, then the insulation can be significant. A ball of expanded clay is built up and vicoristed with expanded polystyrene with a thickness of up to 100 mm.

As far as the method of laying the insulation is concerned, then with vikoristan cork or pinofol, everything is easy to finish. All sheet materials that are glued together with adhesive tape. If polystyrene systems with grooves are installed, then their folding is also not associated with particular difficulties. Mіzh itself teplyuvach stikuetsya for the help of special grooves.

However, do not start the possibility of vicoristing such warming. The most accessible is polystyrene. In such a situation, the next step is to stick the stick to the stick. Mіzh yogo is glued together, for example, with a mounting pin. After the completion of the insulation, the entire area can be covered with insulation.

Let's take a look at the sequence of insulating layers with victorious polystyrene:

- Krok 1. The first sheet is placed in the corner of the place so that the offending sides lie snugly up to the corners of the walls.

- Krok 2. Dali the sheet is placed end-to-end, strongly pushing one to one.

- Krok 3. It is necessary to go around the hut, the column, or else the crossing, polystyrene is easy to cut with a good knife.

- Krok 4. The next row must be laid with small offsets exactly on half a sheet.

If you planned to insulate two balls, then another ball of insulation should be laid across the front to the first. For the rahunok of which sticks do not sp_vpadatimut between themselves. At the end, a special lining with a rosette for the installation of pipes is placed.

As soon as heating is installed on a wooden bed, then mineral wool is used as insulation. Stacked out between the lags. During installation, the width of the mats is to be blamed, but only a few shirsha for the gap between the lags. Tse allow to lay thermal insulation and prevent the appearance of cold weather.

Video: preparation of the base, laying of thermal insulation and reinforcing mesh

Pipe installation

If the insulation is wicked, the time will come for the installation of the contour, which is hot. With this, it is important to accurately loosen the laying, the length of the contour and the number of outlets on the collector. However, before cym varto, discuss the nutrition of the choice of the scorching pipe.

How to pick a pipe

Use a sprinkling of types of pipes, which are used for warm water applications, leather from them are found in different price categories. Vartist tієї chi іnshої trumpet to fall in the vіd vіrobnik.

|

Pipe |

Features |

Approximate/average price per meter |

|

|

The pipes are fitted with special fittings, which make it hermetically sealed. However, it is easy to mess up during installation. Vitrimyut temperature up to 120°C. The stench is sold in bays, which will significantly simplify the process of installation and delivery. |

|

|

|

When heated, the metal-plastic pipe does not deform. The pipe winds up bending and takes the shape after bending. A small group will ask the process of installation work. |

|

|

|

Tse expensive trumpets, yak vikoristovuyutsya very rarely. The stench mayut the lowest riven radius on the bend. The term of operation of the warehouse is 50 years. Working vice 400 Atm. |

Stacking the trumpet

At the stage of pipe laying, one cannot do without a helper. The pipe for heat supply is sold in bays, one for the twist, and the other for the bay. Way of laying to lay down in the system you have chosen. As soon as you fall on a special mother with bobbins, then the robot will definitely say goodbye, smut, dotrimuvatisya to the crocodile. As soon as the beast of the insulation is laid with a rosette, then special clips are used for fixing the pipes. Like a buti, like there is no similar layout? You can work on your own. For whom the vikoristovuetsya vydbivny cord from farboi.

During installation, the pipes are unacceptable, so that the stinks are interrupted. One circuit is guilty of folding from one whole piece of pipe. Start laying out the largest zones. It’s even more convenient if the heat insulation is wicked at two balls. At the first ball of insulation, transit pipes and necessary engineering communications can be placed.

The process of pipe installation consists of a number of stages:

Stage 1 - from the bay 10-15 m. Pull the fitting on one end and connect it to the installed collector.

Stage 2 - The pipe is connected to the collector before supply.

Stage 3 - behind the rosette, the pipe is fixed to the insulation with harpoon-staples. If the plot is straight, then an interval of 40 cm is sufficient. On turns, the interval shortens to 15 cm. When bending, be careful not to break the pipe.

Stage 4 - under the hour of laying, follow it, so that the pipe is not under pressure. Vaughn can be free. Otherwise, the voltage is constantly virivatima brace.

Stage 5 – as if the bracket had broken, let it go 5–10 cm out of the large area and re-fix the pipe.

Stage 6 - if you have bypassed the entire circuit, the pipe is brought back to the collector, and after an additional fitting, it is connected to the wrapped one.

For proper balancing, it is important to take into account how well the skin contour is maintained. The signs can be worked on the collector itself, for example, assign a number to the skin contour, or name the room, where the wine is straight. Vidpovidny notes can be scribbled on arkush paper. Do not varto remember everything. Insulate the pipe section of the varto collector, otherwise there will be a strong overheating of the logs. Above those, it is recommended to insulate the pipe through one, tobto. the insulator puts pressure on the supply, and the return line is left with an undertorque. In this way, the return line does not heat up in the supply.

You can see a few methods of fixing pipes:

1 method : collars, scho are pulled together.

2 method : drіt z soft steel.

3 method : special stapler and fixators.

4 method : fixing track

5 method : mothers with bobbins.

6 method : aluminum base plate

Video: laying warm footings

Armuvannya

Most often, the first ball of reinforcement is placed in the beast of the insulation. In such a way, the fastening is necessary for the help of nylon puffs. Okremі dіlyanki sіtki mіzh themselves zv'azuyuyutsya in'yazalnym drot. Rosemary in the middle of the reinforcing mesh to lay down in the selected crocodile. The mesh is due to the mother Ø5 mm. Krim tsgogo, the beast of pipes is also fitted with a ball of reinforcement. It is explained to us that the grid, that it lies below, will not give any effect.

denunciation

Under pressure, the process may be damaged, which allows you to reconsider in the fact that all installation systems are hermetic, and the pipes do not cause defects. This process is completed without interruption before pouring the screed.

Pressurization can be done in two ways:

- water.

- Repeat.

Pressurized with water

All circuits are due to be re-wired and connected to the collector. The system is loaded through the power supply, the pressure is created up to 2.8 atm, minimum 2 atm. At the same time, the heat-carrying can be buti right up to the mixing node.

- On the back, all the caps curl up, most of the stink of the blue color.

- After that, a crane opens on the supply.

- At the process of filling the pipes with water, a hissing sound can be heard, so you can see if you can get out through the Mayevsky tap or an automatic winder.

- Now the crane is turning on the gate. So it will be possible to lower the water through the faucet to the zlivu on the gate collector.

- The closing contour closes on the fold and suddenly the chergovy curves.

- Install the valve in front of the collector, which is supplied, closes, and the valve in front of the gate collector opens.

After filling the system with water and letting it down again, you need to look around the structure for leaks.

I'll check it out

For an hour during the process of pressing the heat and the logs, the automatic winder will be reopened and the plug will be screwed on the same place. For work, you will need a compressor or a car pump with a pressure gauge. The pressure in case of pressurized repetitions may be greater than for the worker. So create a vice again up to 5 atm.

The similar pressure should be created only in the system of heat supply, and not in the pipeline, which is connected to the boiler and the collector. It is explained, for example, that the boilers are insured less than a vice up to 3 atm. That is why the village is changed later on.

Also, if more than 4 atm is loaded into the system, close the taps for mining. The pressure of falling is not to blame. If you want minimal ventilation, then when the compressor is pumped in, the troch is heated up again, like a cooler. In order to perekonatisya in tightness, you can walk a mile with the sticks.

Screed

If you reach the finishing screed on the right, it is important to transfer a sprat of important cleverness:

- From the system it is not possible to drain the water, but to drain it under a given pressure of 1.5 atm.

- Vmikati heating is occupied.

- Zrobiti temperature seams.

The expansion joint will turn off the possibility of cracking the screed. As a temperature seam, the damper line is victorious. The area of application can be divided into 20 m 2 (it is necessary, as the area of \u200b\u200bone premises is significantly transferred to the display). The pipe, at that dilyantsі, de won to pass through the temperature seam, obov'yazkovo zamіtsnyuyut corrugation.

To fill the screed, it is recommended to use special additives to improve the technical characteristics of the screed. In addition, a plasticizer is added to the concrete, which prevents cracking of the screed during cooling / heating.

Warehouse concrete:

- Concrete and vіdsіv - 1:6.

- Concrete, sand and rubble - 1: 4: 3.5.

The plasticizer and other additives are poured in during the mixing of the concrete sum. The proportion is determined by the selections from the collections of the picker, from the labels.

For residential applications, a finishing screed of 50 mm is sufficient, for factory applications up to 100 mm. With whom it is important to protect such power of the screed - heat accumulation. Chim the screed is thinner, less than an hour out, save the heat. If it will be too late, then more thermal energy will be needed to warm it up. Therefore, the optimal thickness of the screed is 70-80 mm.

Before pouring, perekonayetsya, scho in the system of heat podlogi є vice 1.5-2 atm. Vmikati obіgr_v at the process of hardening the concrete is fenced.

The process of making a screed on the beacons is in the step:

- Metal beacons are displayed behind the equal.

- Lighthouses are not built on trumpets. It is possible to build a dense rozchiny at the sight of humpbacks, lighthouses are installed on the yak.

- The concrete is smoothed out by the rule. At this point, it is important to perekonatisya, that the bulbs appeared more and more from the body of the screed.

- The coming day, if the concrete has not yet accumulated, it is necessary to remove the lighthouses, clean the city and fill it with rozchin.

Video: screed pouring

Commissioning

Enter the working temperature in the following steps. Put a temperature gauge up to 25 °C on the back of the head. After a skin day, raise it by 5 ° C. As in the quality of heat transfer, antifreeze is vibrated, the increase is increased by 5 ° C, and as water, then by 10 ° C. This is important, the shards can be destroyed by a sharp and uneven overheating, after which the screed cracks.

Otzhe, commissioning is consummated in such a rank:

- Change, that all the taps on the collector are open and the circulation of the heat carrier is behind all the circuits.

- The thermal head of the zmishuvach valve is set to the minimum temperature indicator.

- The circulation pump turns on when the boiler is turned on, but the pump on the boiler turns on.

- Sometimes it is necessary to play against everything that has accumulated.

- For additional vitratomy, reversing the circulation of heat in all circuits.

- Then you can turn on the heating.

Video: system filling

Prices for water heat pidlog

Vartist robit, fallow in the place of residence, may slightly change. In the middle, the values show validity. You can look at the prices in the hover table.

If you have vicorist profiled heat-insulating plates, then it is enough for you to fix the pipes in special grooves with one push on them. Alternately, you can win a different type of thermal insulation, but also a wonderful option - to lay a reinforced mesh with a streak of 3 mm and a diameter of 10x10 cm in the middle, yak, cream, a stronger screed, to build one more coris on the right - you can use our heat pipes until it or with clamps. , but not very strong, so that when heated, the pipes can be deformed due to the different thermal expansion of the materials (the pipe itself blows). You can also buy special clips and fastening stitches, with which the pipes are fastened without intermediary on the balls of heat insulation. The pipes are fastened with a crochet of 1 meter. Schemes, behind which the pipes are stacked differently and among the people they can be called different: snakes, snakes, ravliki, zigzags, a spiral with a shifting center, etc. pipe laying for do-it-yourself water heaters.

1 laying of pipes for warm water pipes near the looking snake.

This method demonstrates the laying of pipes one by one at the sight of a snake, which is also called parallel. It is good to fit for the accommodation of a small average area and lay it more often from the side of windows or walls, which is called a booth, so that at the entrance of the pipe you know there is the highest temperature.

2 Spiral pipe laying do-it-yourself water heaters(at looking like a ravlik)

Tsej sposіb sposіb stosovuvati better in the areas of s pіdvishchenim teplospozhivannyam or primіshchennyah z large area m2. The great advantage of this method is that if one pipe is cold, it will compensate for heating, and the pipe that feeds and returns (supply and return) run parallel to one another. The laying of pipes in a spiral way, from 10 to 30 cm minimum distance between them you can revisit 8 divs.

Connection

After that, as you have blown the trumpets in this way, which is better for you, and fixed them, be it in the most lucid ways - one end of the trumpet will come to the collector, and the other - to the gate. As the room is large, there are a lot of contours (such loops) and collectors are selected according to the necessary number of entrances (exits). Bazhano, so that the skin loop was formed from a solid piece of pipe, so that the additions of the z'ednannya would increase the risk of leakage. It is also necessary to make a deformation seam in that case, as the length of your room is more than 7-8 meters. This seam is necessary for compensating for thermal expansion and it can be prepared with the same damper line, as it was previously victorious. Temperature seams are responsible for dividing the skin contour, as there is not one wine. In that case, if the temperature compensation seams pass through the pipes of the heat pipe (supply or wrapping), on these pipes it is necessary to frontally cover the corrugation with a length of 40-50 cm. , having cut the corrugation across from one side and put it with a cut down on the pipe in the place where the temperature seam passes.