Like trumpets for singing are the best vicorist in scorching systems. Robots for sealing the emergency pipe. Option #1 - black metal parts

Starting life wet booth, leather gospodar Mrіє bachiti yogo warm, quiet and beautiful. We do everything in order to make our booth become like this: we think over the most details of the improvement, we fix exclusive furniture, we develop the original landscape design. For all these troubles, you won’t have a good feeling, as it will be cold in such an ideal booth. Wait a minute, appreciate the beauty of the decoration and the sturdiness of the furniture, if you don’t “tap a tooth”. Also, it is necessary to pay special attention to heat insulation for the installation of the scorching system. It is better to entrust the development of the project to the fakhіvtsy, and choose the boiler, vihodyachi z necessary pressure and available to you paliva, not a warehouse of special difficulties. The trumpet for singing has been lost - it’s better to vibrate at once.

The first to choose the trumpet, it is necessary to be appointed, for some criteria of cerebration - as a quality of that chimney type of trumpet is important for us. There is a lot to lay around depending on what type of scorching system your booth has. Otzhe, the axis of the list of vihіdnih data, yakі nebhіdno mother when choosing pipes for scorching.

- Type of scorching system - primus stove self-fueling

- Bookmark method - use the middle of the wall or call

- System configuration - simple and foldable

- Average and maximum pressure of the system

- Average and maximum temperature in the system

Depending on these data, it is necessary to evaluate the skin type of pipes and choose the best option for your system.

Varieties of pipes for scorching

How do you blow the best for scorching? How about steel? Until recently, such trumpets were much wider. Moreover, the scorching system could be installed without them, there was no alternative. Ale, no varto is put before them, as if it were a relic of the past. In certain situations, black metal pipes are the best option. For example, in a system of self-propelled autonomous scorching, de є nebhіdnіst vykoristannya pipeline of great diameter, vikoristannya steel pipes can be called tsіlkom vipravdanim.

Steel trumpets for scorching are now vvazhutsya a relic of bygone fates

The main advantage of this material is materiality. Steel trumpets are practically impossible to harm with a mechanical path. Small linear expansion allows expansion joints to disappear. I, singsongly, the most important thing is durability - resistance to high temperatures. Vugletseva steel, from which the stench is prepared, the building vitrimat temperature up to 1500 degrees. In addition, in the system of scorching, mounted from steel pipes, you can constantly raise the high pressure. I didn’t bring it to sealing, obviously, it’s less than that, as the sealing work was carried out professionally.

Axis here we vpritul pіdіyshli to nedolіkіv tsgo material. Nasampered skladnіst installation. For the installation of air pipes, you need a brewing apparatus and a qualified brewing machine. Varto signify that the servants of the rest are more expensive than satisfaction. This pipe dimension makes it easy for your installation.

It is necessary to choose the steel system of scorching only until the cob of work is done in the application, otherwise it is possible to build a priming and trellis, and pidloge pokrittya. Well, for some reason you are starting the installation of a scorch at an already repaired room - look for an alternative to steel pipes.

Heating of steel pipes is not carried out in a renovated apartment, so all works are expected to be repaired

Due to the strength of the "black" metal of corrosion, it is not recommended to twist it when installing the attached pipeline (in the middle of the wall). Well, up to the shkidlivy vlivu vloga on the inner surface of the pipe, then in the system of autonomous scorching it won't work. On the right, in the fact that in such a system for a thriving hour circulates the same heat-carrier, the kisen from which it boils is steamed, and, therefore, shkidlivy infusion on metal it is much less. Dosvid shows that steel pipes in private houses can last for over 50 years.

One more short steel pipe can be called the not-too-pretty good-looking look and the need for regular maintenance. Such a pipeline will require a farb, and the shards under the high temperatures of the farba should be peeled for an hour, the rulers will have to bring a cover.

High thermal conductivity can be seen both to the top, and to short steel pipes. If part of the pipeline passes through the application, which is not singed, then the heat loss on this space can be significant, which means that the pipe needs to be insulated. In the middle of the house, the heat conductivity of pipes can play a positive role, increasing the supply of heat.

The price for black metal pipes can be called democratic. How can you spare yourself in the services of a zvaryuvalnik - a system of scorching from such material will, perhaps, be the most budgetary of all possible ones.

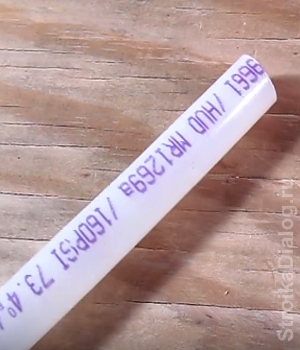

Polypropylene pipes - exchange for temperature

Another inexpensive option for the installation of the opal system is polypropylene pipes.

Polypropylene pipes for scorching are to be selected according to special standards - only those options, which can be victorious for high temperatures.

The cream of its cheapness, the material of which is breathed in by other positive qualities. Before them you can see:

- It's not a big deal - the installation of a scorching system from such pipes will not cause an increase in the burden on the load-bearing structures of the building.

- The inner surface is smooth - such pipes do not “overgrow” with a vaporous infusion, they do not settle down on them, and also, the inner cut of the pipe will be left with an inevitable rich rock.

- Durability - pipes made of polypropylene can last up to 20 years, saving all their strength.

- Resistant to low temperatures - when the scorching system is turned on, you can not be afraid that the pipes will “freeze”. Tsya ak_st to rob polypropylene piping is ideal for installation in zamіskih booths, de masters live fast, they come less often, they are different.

- Starry look– polypropylene can achieve an aesthetically pleasing look, it does not require regular fermentation and does not change the color.

Unfortunately, this material is not ideal and may have its own shortcomings.

Necessity of soldering - this factor can be brought to the point of nedolіkіv mentally. If you need to get a specialist to weld metal pipes, then you can solder plastic on your own. A soldering iron for plastic pipes can be rented in budіvelnyh shops, practically no matter where, and learn how to use it - on the right 5 quills.

Soldering iron and kit for soldering polypropylene pipes

Polypropylene does not bend - in order to make the pipe turn, it is necessary to bend the fittings, but it is not too easy when installing the system with a folding configuration. If you want, you should indicate that the fittings for polypropylene pipes are low.

Low maintainability - it means that in case of failure of one of the pipelines, you will have to replace one line from the fitting to the fitting.

Low hardness of the pipe - under the influence of temperature, mounted on the wall, the pipe can sag on the gap from one to the other.

Important! When installing the attached scorching system (in the middle of the wall) from polypropylene pipes, it is necessary to repair the linear expansion of the piping pipe with a length of 5 m and become 4-5 mm. To ensure the safety of the improvement, the walls must be installed on the pipeline required quantity compensators.

Low thermal stability - the most significant shortfall of polypropylene pipes. In our climatic zone in the winter period, the temperature again often drops significantly lower than zero, which leads to an increase in the heat transfer temperature. Unfortunately, the working temperature of plastic pipes is less than 70 degrees, and the temperature of 90 C stench is only seen for a short time. More details in this video:

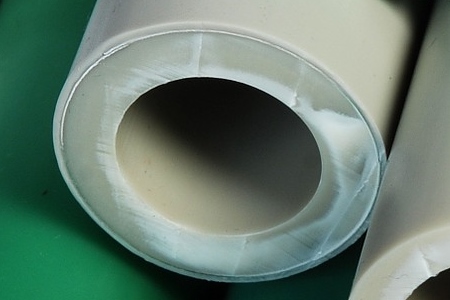

Pipes made of cross-linked polyethylene (PEX)

Such pipes are vibrated by the technology of "sewing polyethylene", in the process of which the additive links between molecules are blamed.

Blow out sewn polyethylene for singing, you'll be fine!

Before transferring the material, you can add the following characteristics:

- High availability of polyethylene.

- Resistant to high temperatures and vise - the working temperature of the material becomes 90 ° C.

- "Effect of memory" - if such a pipe is bent in a heated state, then after reaching it it saves its shape, and when it is heated again it straightens up. Qiu quality can be successfully achieved in the installation process.

- Durability - the term of the PEX-pipe service is about 50 years old.

- The weight is small - it does not create a burden on a load-bearing structure and makes installation easier.

- Ease of installation - by choosing a system, you can twist the threaded fittings or press fittings, which do not require additional equipment.

- Resilience to "overgrowth" - the light of the pipe is filled with the inevitable stretching of the current term of exploitation.

- Such pipes can be mounted in the middle of the wall, the stink cannot be great linear expansion and not weak to corrosion.

Video about those who trumpet like this:

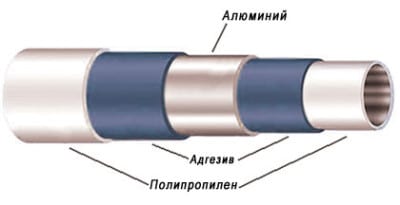

Metal-plastic pipes - optimal sp_v_dnoshennia

Tsey type of pipes for burning stay rocky becoming the most popular. Vіn poєdnuіє іn іt's own all the best qualities of steel and plastic pipes. Tse became possible for the richness of the rich structure of the material. The inner ball of the chiming trumpet is made of smooth polymer, which will protect the appearance of a siege from the water. Inner ball, thickness 0.2-0.3 mm, made from especially plastic aluminum foil. Zovnishniy ball of plasticity of calls to defend metal from a negative infusion dovkilla. For joining the balls, a special glue is used with an arc of high adhesion, both to the polymer and to the metal. The very sticky warehouse of the day will come out more mіtsnim and plastic.

metal plastic pipes in the middle

Before non-peripheral transgressions, the material can be seen:

- Smooth inner surface.

- Aesthetically sound look - the trumpets do not turn off the farb, and they do not change the color under the influx of sleepy changes.

- Ease of installation - the system is selected for additional obtisk or press-fitting without the need for special equipment.

- Dovgovіchnіst - properly mounted system can last for over 50 years.

- Savings on rozkroї zavdyaki vіdsutnostі prіzkіv pipes. The metal-plastic pipe is sold in bays, which allows you to buy the very quantity that you need.

- Vidsutnіst static – the material does not conduct blukayuschie streams.

- Ease of repair - enough rose fitting and replacement of the zipped pipe pipe.

- Vіdsutnіst іnіynogo razshirennya - you can boldly vmuruvat piping near the wall.

It’s a pity that this material may have its own shortcomings, although it’s not rich. The most important of them is the price. And since the quality of the pipes themselves is not so high, then you will have to be kinder to buy fittings. In addition, the conduit elements themselves may cause a small amount of noise - the sound of perforations, which calls for a decrease in the throughput of the pipeline. This material is categorically not suitable for selection in dacha booths. When freezing, the pipes will inevitably burst.

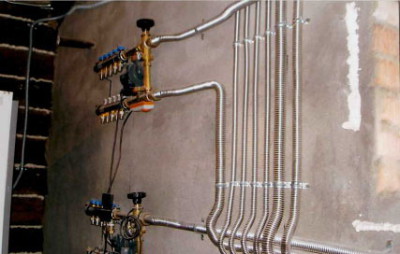

Scorched from mid-pipes - expensive and effective

Like in food, like a trumpet vibrati for scorching, the price is not virishal for you, obov'yazkovo respect for the middle trumpet. It is not for nothing that this material has been victorious for the production of pipes for more than one century and has not lost its relevance. The most significant advantage of midi over various polymers is a wide range of operating temperatures. Such trumpets can transport the homeland, heat up to 500 C. It is not terrible and the most severe frost. Obviously, it’s not safe to put the system in a non-living booth for the winter, but for some reason, the water in the pipes froze, and the pipeline itself can be protected. The same can be said about the failure of the water hammer.

Scorching for the help of mid-pipes to finish the road, but even more effectively

The possibility of self-assembly of such pipes calls for great sumniv, so it is necessary to use them for additional soldering with solder and capillary fittings.

Zavdyaki smooth inner surface of the lumen of the pipe will be permanently left behind, and the corrosion damage will be ensured by safety. The middle term for the service of the mid-trumpet is about 100 years old. Vikoristovuvaty so trumpet varto less there, de piping do not go beyond the borders. The reason is for the high thermal conductivity of the material.

In addition, the mid pipe is just wonderful. With the rocks of the middle, the trochs change the color and turn into a patina, which will give your interior a vishukanist.

Pipes from stainless steel - quality and price

Stainless steel - ce, perhaps, the only material for the manufacture of pipes, which can be seen from the middle, not only in price, but also yak. As you might call it, such trumpets do not rust and do not overgrow. The stench rejoices with a high thermal conductivity and even a trivial term of service. For sale, you can find two types of stainless steel pipes, which are made in one type in one way.

Like vicoristovuvatimete so trumpet - take subtleties

Zvarnі trumpets are made from a sheet of steel for additional zvaryuvannya. The stench can be used for the installation of the opal system, or the possibility of leakage, in such a rank, is significantly increased. Not to be found about those that the pipe burst in the next month and navit at the nearest rock, but remember that the repair of the stainless steel pipeline will cost you a tidy bag.

The possibility of penetration is significantly reduced, as you have made it seamless stainless steel pipes. Varto designate, what їhnya varіst is signifi- cantly greater, lower zvarnyh, and the term of accident-free work is greater.

Virobniki proponuyut thick-walled and thin-walled pipes from this material. The first ones, as a rule, are vikoristovuyutsya at the prepared drilling rigs and other plots with high vimogi to the minuscule. Stopping them in the home opiate system is absolutely not docile. In a different way, it’s expensive, but in a different way, to create an additional ambition for the foundation of life. Thin-walled trumpets blow as a whole. Your reserve of minerality is enough for bagatoric work of your system. Installation of the pipeline from stainless steel varto doruchiti fahivtsu.

So what do you take anyway?

Having reviewed the report information about the characteristics and features of all types of pipes for scorching, presented on the domestic market, you can get notifications of your choice. It’s not a hell of a lot to save money, even a scorching system is the whole part of your booth, like a call to serve a rich rock. And її out of tune can cause impersonal inaccuracies.

In this article, we will try to fix all the nuances and suggest to the owners of private booths the optimal variety of pipe fittings for the scorching system of private booths.

Various pipe fittings for scorching systems

Virishyuchi, like trumpets, are more likely to vicorist for singing a private booth, the vlasnik of a life will happen to vrahuvat a sprat of factors, which allows you to select the optimal variety and type of fittings. Such factors can be seen: the type of expansion of the heating system itself, the surface and the heat resistance of the future, the readiness to beat the pressure on the surface () and the variety of the reinforcement material.

According to the tradition that has developed, all pipes for singing a private booth are classified according to the type of material that is used for making similar fittings. Therefore, in the commodity nomenclature of modern pipe plants, there are three different products:

- Metallic - to cast reinforcement from steel and midi, using the method of cold and hot rolling. Moreover, on the scorched go, the products are seamless due to the relatively small sizes.

- From structural polymers - such reinforcement should be made of cross-linked polyethylene (PE-X) or polypropylene (PP). The selection of these varieties of plastic is explained by their high thermal stability. The stench does not waste structural hardness when transporting heat transfer heated up to 90-95 °C.

- Two-component, metal-plastic - similar products are made from sewn polyethylene (inner ball) aluminum or copper foil (reinforcing insert) and polypropylene (outer ball). On similar tricks, go through the possibility of moving a vice at the pipeline.

How do you blow the best for scorching in a private booth? Notice to food chain Briefly describe the following conclusions about all the advantages and shortcomings of all structural materials of pipe rolling, as well as the specifics of the installation of scorching systems from these materials.

Steel and copper trumpets - advantages and shortcomings

The vrobi zі stіlі stand vіdnosno inexpensively (like for metal fittings), they are easily zginayutsya under some kind of kutom (after painting until blackened) that vitrimuyu majestic vise (up to 25 atmospheres). Such fittings are connected to steam generators, and hot water boilers. Moreover, in this particular situation, there are no common fencing, neither due to the surface of life, nor due to the peculiarities of the breeding scheme, nor due to the temperature of the heat transfer.

The steel pipe is universal, but there may be a great nedolіk - it's rusty. If in the middle of the fittings the process of corrosion does not hurt anyone (it’s less than 40-50 years to go through the wall of idle time), then the oxidation of the outer surface of the pipeline does not calm down either the housekeeper or the interior designer. That is why steel pipes are fired and/or filled with heat-resistant warehouses.

The middle pipe was spared a little more. Such fittings can be left out of the air at all, having turned into a part of the interior. And the term rental service from midi is less tolerant of a homeowner, who does not change the individual scorching system. Such combinations can be hundreds of years. In addition, copper is plastic (it is easy to bend with hands), it is good to conduct heat and trim the temperature of the wear in the ranges from -200 to 250 degrees Celsius.

Zavdyaks to this fitting and pipes from this material are protected from the fall-free defrosting of the system - the stench will not burst for the daily furnishing. And even in such pipes, the inner surface is supra-smooth (the coefficient of friction is smaller, lower for polyethylene fittings), so the flow of heat can be expanded to an arc of high fluff, ensuring the temperature difference at the pressure pipe and wrapping at a level of 5-10 ° C.

The only short pipe made of midi is the high price of such fittings. At the result, the answer to the question is: "What kind of pipes are singed in a private booth - steel or medium?" Aje black rental is cheap for colorful metal, although it is more qualified, and therefore better than a paid elector.

Fittings made of cross-linked polyethylene, polypropylene and composite metal-plastic are important less than copper and steel pipes. Therefore, when laying the system of scorching, polymers and metal-polymers will produce less trouble and inconsistencies. Such a heat pipe is laid one by one or by two people. With this light pipe, it is possible to mount not only on the supporting wall, but also on the intermediate partition.

In addition, all polymers do not rot, do not rust, do not react to bacteria, and they demonstrate even a low coefficient of friction, allowing you to increase the speed of the flow and protect the heat in the boiler for the fluctuation of the temperature increase at the turnpike. And if you pipe with plastic, it is easy to bend, so it is no less than a fitting, but like a radiator in a scorching system of the "warmth of the log" type.

Polypropylene can be bricked up against the wall without fear of thermal expansion

To the extreme achievements of polymeric fibers, it is possible to carry and weakly heat conduction (more energy goes to the radiator), as well as a small coefficient of thermal expansion. Such fittings do not burst in the cold and do not break the strobe when laid.

The following facts can be added to the individual advantages of polymer pipes:

- Polypropylene can be bricked up against the wall without fear of thermal expansion.

- Metaloplastik can be vikoristovuvaty at the rich top boudinki - deakі grades of fittings vitreous vise up to 16 atmospheres.

The main minus of reinforcement made of polymers is the high degree of stiffness to mechanical processing. You can cut a metal-plastic pipe with a great kitchen knife. In addition, such fittings can only be connected to water-heating cauldrons. Steam generators in times are categorically contraindicated.

The sewn polythene is vitrified by constant heating up to 90 degrees and short-time temperature rise up to 110 degrees Celsius.

When I look around, I’ve been asked for a power supply: “How do you blow vicorist to scorch a private booth?” - Ask yourself. Obviously polymeric! Aje for all the pluses stinks and it's incredibly cheap. Ale, do not hurry with the whiskers. We will have to learn about the specificity of choosing heat conductors from metals and polymers to the residual cost of supply bags.

To fold the steel heat pipe, you need a grinder, a blasting machine (for electric arc or gas blasting) and a wrench. And why navit obshtuvannya ros'mnogo z'ednannya (on the clutch) vimaga pre-installation to the pipe of the threaded ring (butt with a groove). To install such a pipeline, you need a slusar and an electric welder.

Polymeric heat conduction is selected for pressing and compression fittings (pinned sticks), for diffusion soldering

Mid-section fittings are assembled on obtisk or compression fittings and for additional soldering (on capillary fittings). For folding such a system of burning, only a slyusar is needed, and before a set of tools, a soldering iron, embroidery and rose keys are needed. In addition, you need fittings, solder and flux.

Polymeric heat conduction is selected for pressing and compression fittings (pins), diffusion soldering. Moreover, the entire process of installation of adaptations for a low-skilled selector, which is more than enough to fix the fitting on the butt of the butt joint, behind the help of a special charging device and press them one to one. With minimal skills, work with your hands with the installation of plastic pipes, be a kind of housekeeper.

Metal or polymer pipes - it’s better to victorist, if that’s why

Otzhe, we are aware of the advantages and disadvantages of fittings, as well as the particularities of installation. Therefore, now we can sing like a trumpet vibrati for singing a private booth, spiraling on facts, and not on those sensitive similarities. І cі facts pіdshtovkhuyut us to such vysnovkіv:

What do you have rich-surface boothі steam scorching, then the best option for you will be the steel pipes themselves. The stench vibrates and the temperature is high, and the vise is significant. In addition, steel fittings should be used in different cases of cladding with gravitational spontaneous circulation of heat (if the vines collapse with self-fueled pipes). Aje, in any case, you will need pipes of great diameter and high construction hardness.

Vlasniks of richly-topped budins, or of small-surfaced inhabitants of the great square, scorched for the help of a water heater, rather choose the middle trumpet. The stench vibrates the high pressure at the system and does not galvanize the heat-carriers at the pipes, provoking the overheating of the fire. In addition, since you had a lot of koshtіv on the houses of the great square, the variety of copper fittings is unlikely to rattle you.

The rulers of low-surface residents from the middle area and the water-heating boiler as a heat generator are better off vikoristovuvat metaloplastikovy pipes. The stock of value of such fittings should be sewn onto the lining of the system at a two- or three-overhead booth, and the low price and simple installation will serve as a bonus to the benefit.

Vlasniks of small, one-surface buds can vicorist pipes made of sewn polyethylene or polypropylene. In such booths, the scorching system can be installed with your own hands, connecting a home boiler without an armchair and radiating fahivtsiv, and pipes made of plastic are best suited for this.

The scorching system is an invisible storage of communications networks, whether it be a booth. Yaki trumpet vibrati for scorching a private booth smut food on the way to obshtuvannya garnoyta effective system heat pipe.

Yaki trumpets for the scorching system

Warehouses for the heat pipeline according to the material are subdivided into:

- Metal (steel, copper, stainless steel);

- Polymers (polypropylene, PEX - sewn from polyethylene)

- Combined metal-plastic.

Crimean material, when choosing, must be insured:

- The type of opal system is self-fueled or with primus water;

- Type of system - foldable or simple;

- Roztashuvannya system - the middle of the wall abo call;

- Heat transfer temperature;

- Tisk at the fence.

Qi factors determine the necessary materiality of the pipes, the thickness of the walls, and the resistance to heating. So we must think different ways installation, for certain needs of a variety of special devices.

How to choose a trumpet for scorching, to obshtuvat yakіsnu that nadіynu system? Let's take a look at all types of varieties and see the best.

Steel (black metal)

The most common and until recently one of the widest - steel pipes. The stench is effective from the point of view of heat transfer in the premises, but the transfer becomes short when passing through the non-fed premises, the same effective waste of heat is shown, but if it becomes a problem - water reaches. That is why the plots, roztashovani on the street or in the basement, which are not scorched, are to blame for additional heat insulation.

Advantages of steel pipes:

- Available price;

- Effektivna teploviddacha;

- Small coefficient of linear expansion during heating (pipe pipes to extreme heating), the system does not require the installation of compensators.

Black metal has more shortcomings:

- Folding installation, which can be realized only for zvaryuvannyam.

- The installation of pipes is less possible to the cob ozdoblyuvalnyh robot. If it’s not a problem to keep the house running, then with the repair of the system it’s more complicated: brewing robots great risik poshkodzhennya trellis that pokrittya.

- Shilnіst to corrosion unprotected steel zmushuє gradually revitalize the lining of the outer shell, the inner wall of the steel to the water and do not overgrow with irzhey. Tsya vada maє, shvidshe, aesthetic character.

As if you didn’t believe, with such pipes it’s better to scorch, fakhіvtsі recommend giving respect to other types of heat pipes. Unprotected steel is the most suitable for attaching the main internal line. The term її service - over 50 years.

Stainless steel

At the front, stainless steel is super protected from corrosion from the inside and outside. Tse is the best option for spіvvіdnoshnіnі price-yakіst.

Pipes for scorching from stainless steel have unique characteristics:

- The stench is stable to heating, practically not strong enough to linear expansion;

- Suitable for installation of a system with a primus rush water under a high vice;

- High heat output;

- Durability without changing the primary characteristics;

- Resistance to mechanical strength.

Pipes from stainless steel are produced in two types:

- Products with a late seam are made from sheet metal rolled products. Characteristics of such grains lie without middle in the quality of the welded seam and die of the welder.

- Seamless sewing is much more expensive, but the quality of their work is an order of magnitude higher: the pipes leak more easily and practically do not require repairs.

Trumpets can be thick-walled and thin-walled. For the organization of the internal heat pipeline, it is optimal to choose the slabs with thin walls.

Mid

In nutrition, yaki trumpet better choose for scorching, the answer is unambiguous - medium. This material, which is warmer for other weather, is not weaker to corrosion, can be found in the most unfriendly minds, and the term for the service of a copper pipeline with proper installation is 100 and more years.

Features of the copper heat pipe:

- Building lines vitrimuvati heating up to +500°С. Obviously, the homeland in the system does not reach such a temperature, but the pipes must always have a reserve of minerality in case of a non-transfer situation.

- The strength of the walls is enough to withstand the different forces of the hydraulic impact.

- The peculiarity of the midi is the daily reaction with sourness and the richness of chemical speeches. That's why on the inner walls you can't settle for pouring after 100 years.

Like in steel, in medium-sized ones, there is a heat supply, but it’s less important when there are significant measures in the middle of the place. It is necessary to insulate the heat conductor with insulating material on non-salted pits.

The installation of copper pipes depends on the participation of fahivtsiv: the pipes are soldered with capillary fittings and silver solder.

The main shortfall of the copper heat pipeline is the arch of the temple of the warehouse bins.

Polypropylene: efficient polymer

The most requested pipe material is polypropylene. Wine is inexpensive, accessible and versatile. Pipes made of polypropylene have a number of benefits:

- Small vaga including the need for hard fixation to the foundation, lowering the hardship on the foundation.

- The smoothness of the inner walls, including the dampening of build-up and build-up, which could make it difficult for water to flow in the system from time to time.

- Permissible temperature range for polypropylene pipes is 0…70°C. The upper boundary of the permissible heating must be protected from the distance, in order to prevent overheating of the heat carrier and the pipeline.

- The trivalent term of exploitation is not less than 25 years.

In principle, pipes from polypropylene are not a bad solution for organizing a heat pipeline, but only with a thinner, so that the water in the system does not heat up over 70 ... 75 ° С.

Insufficient amounts of virobiv іz PP, yakі nebhіdno vrakhovuvat:

- Pipes do not bend, installation is required for additional fittings. On the skin turning space, you will have a chance to work the kutov stick of the windbreaker.

- Small stiffness of the walls does not lead the building to sink water under a vise, water hammers in the fire can be fatal for the pipe. In most vipadkіv okremі dіlyanki simply sag or sag through different vplivi (overheating, hydroblow, mechanical damage).

- Pipes made of polypropylene do not need to be repaired;

- Low resistance to high temperatures does not allow for an increase in the heating of heat during frosts, if it becomes cold in the house.

- Linear expansion of pipes to become an average of 4 ... 5 mm per 1 linear meter. Tse zmushuє vikoristovuvati at the compensator system.

Polypropylene tubes are needed for the help of the brewing apparatus, which can only be done by professionals, for which you need a certificate and qualification. You can't do the installation yourself.

PEX - sewn polyethylene

Sewn polyethylene is the latest efficient material for the production of scorched pipes. A new polymer molecule is “sewn”, which gives rise to an increase in mentality and hardness.

Here are some tips for making PEX pipes:

- Increased density of polyethylene in the same material, equal to the same polymer;

- Promoted thermal expansion up to 90 ° С, which is viable in terms of vіdrіznyає vіrobi vіd polypropylene;

- The system of building vitrimuvati movement of the water at the fence;

- Smooth walls pereskodzhayut utavlennu nalota on them;

- Small vaga zvіlnyaє bearing constructions in the form of supplementary suttєvogo navantazhennia;

- Sewing polyethylene bends when heated, changing its shape to an uncoated cyclone “heating-cooling”. Tse allows you to beat the pipes for installation on the plots of different folding;

- The minimum linear expansion of the pipe does not require the installation of compensators on the main line, the system can be "captured" into the wall or under the log;

- Warranty term for PEX pipe service is 50 years.

Pipes are mounted for additional fittings with threaded fittings or press-fittings, which will make it difficult to overcome the additional possession.

Metaloplastik

Like trumpets better vikoristovuvat for scorching a private booth, so that the price did not bite on them, like on the middle? - Zrozumilo, metal-plastic. Tse best material in the segment of spivvіdnoshnі "price-yakіst".

The metal-plastic pipe is made up of 3 working balls:

- 1) Inner polyethylene pipe, resistant to high temperatures. Її ideally smooth walls do not encroach on minerals and salt, stench does not appear at the sight of growths from time to time;

- 2) The load-bearing aluminum ball establishes the supra-frame of the tube, which secures the high strength of the virobu and the resistance to the high vice;

- 3) An ominous polyethylene ball, which protects the internal air from other unfriendly inflows.

All balls are super glued and create a single structure with unique characteristics:

- The vaga is small;

- The minimum linear expansion allows you to install the pipeline both in front of the system, and in the middle of the walls, screeds;

- Metaloplastik p_dhodit for the system of burning, hot and cold pipelines;

- The movement of the city, interchanged with other plastic pipes, the pipeline of the building vitrimat and the death of water hammers;

- Pipelines do not overheat, do not sag;

- Tubes are sold in coils, free to bend within the allowable radius;

- The inner and outer walls superbly protect the aluminum, the wines do not suffer from corrosion.

Pipes for metal-plastics are mounted with threaded fittings for the participation of fittings, yakі є weak hand systems. When frozen, brass z'ednuvachi become unacceptable. Compression fittings periodically require maintenance (lifting, replacement). The sounds of the soundings of the nearby farms can overstep the normal circulation of the water.

The cost of pipes for metaloplasty is significantly more expensive than for other polymeric analogues.

Trumpets for scorching: the best for a private booth

There is no single-valued food supply. Vybіr slid robiti, spiraling on different furnishing:

- Who is viroblyatim installation? If you want to independently install a heat pipe line, you need to choose a choice of threaded fittings: metal-plastic, polyethylene. For bazhannya choose a metal or a medium system, to be able to speed up the servants of professionals.

- The budget plays an important role in the choice of pipe material. Even though the price is not important, it is unambiguously followed by the arrival of a medium heat-conducting fiber, the stench may be the best performance indicators. Finding the choice of choice is not bad, you risk paying for savings: budgetary pipes are quickly becoming unacceptable. Polypropylene is deformed during overheating and needs to be replaced. Tsya the problem is turned off only with a strict pretrial temperature regime.

- How long can the system be maintained? Like an old house, it is necessary to organize a timchasovy heating pipeline, not to overpay for the cost of electricity. With a new everyday life, insanely, better, it’s better to see the priority of pipes made of metal.

In the skin region, there are many types of polymer and metal pipes, from which you can buy more kits for choosing a scorching system. When choosing a post-employee, the scale of the enterprise is constantly spiraling, often small firms supply the market with domestic pipes. Golovne, scho need to request - sertif_kati vіdpovіdnostі virobіv standards and protocols of control viprobuvan, yakі pіdverdjat yakіst goods, shcho kupuєtsya.

For another twenty or thirty years, only radiators made of chavun and pipelines made of steel were introduced to the market of scorching systems. Immediately, the situation changed radically, and about those who trumpeted better for scorching, praising the rich of ordinary people.

Pipe selection criteria

Use a little parameter, how to choose, how to possess it is necessary to choose for the scorching of that which is another application:

- like a scorching scheme is victorious: it is simple, without additional configurations, it is foldable, with important assembly robots;

- laying method. It seems that the pipes are installed at the bathrooms, the kitchens and the toilets are either modern or attached. Pipelines are installed at the wall, under the foot, in the middle wall panels or drywall frame;

- the scheme of the opal system is also important, as it is possible to lay on non-opalized places (pіdval) or be heated;

- heat transfer temperature and working pressure;

- ease of replacement and repair;

- also, the choice may lie due to the fact that you know the operation of that chi other material that could be used before installation.

Now let's look at how popular the pipes are at the same time on the wakeful market.

Steel systems

In rich Moscow apartments and private booths, the steel pipes themselves are installed from water scorching. The stench is made from carbon steel of high hardness. The main advantages are durability, resistance to pressure drops, hydraulic shocks. You can, without suspecting your conscience, wink for hot water supply and scorching. The versatility of such pipes is not high.

If there were no alternatives to steel pipes in systems central scorching

Nedoliki polagat schilnosti to corrosion, through which the stench leaks and goes out of tune. In the middle of the stink, it can become confusing, which negatively affects the building’s property throughput. For the installation of steel pipes, you will need special skills, so that the work is being done. Zrozumilo, it is possible to make a threaded thread, it is also not easy to work with them. For example, it was necessary to chimalo zusil, to cut the carving on the pipes.

The most durable system is made of stainless steel, since this material is not weak to corrosion. Also, in good vitrimuє high vice. Tsі two yakosі vigіdno vіdrіznyayut yogo vіd vіd ugletsї ї sіlі.

Zvertaemo respect on the middle pipe

The stench was always associated with nadіynіstyu and yakіstyu. Suitable for opalescent systems, and hot water supply. Zavdyaki resistance to corrosion, such a pipeline will be in operation for a long time. There are two types of stench for sale: burning and non-burning. The first one is better deformed, the other one is more likely to stagnate at the refrigeration unit. The only small midi - even a high price, shards in the main supply of this material are charged because of the cordon.

At the same time, it is impossible to block aluminum radiators together with midi pipes, since these materials pass through the heat-carrying medium, enter into a chemical reaction, and electrolysis is established.

Polypropylene: economically reasonable

The best cheap trumpets that you have proven yourself. In the scorching systems, the pipelines are less reinforced with polypropylene. If there are unreinforced pipes, then the stench must be done with unsafe ones, as if they were beaten for such purposes. Thermal pressure can bend the pipe or break out of the fixing, which can lead to an accident.

Zovnіshnіy vyglyad polipropilenovyh piping ta z'ednan for them

There are three different types:

- triballs, as if reinforced with aluminum from the outer side. They are made of metal sheet covered with plastic. In the middle - a ball of polypropylene;

- triball pipes, which are reinforced with aluminum in the middle. Additional balls: polypropylene zvnі and in the middle, as well as metal between them;

- analogues are also produced, reinforced with fiberglass in the middle. Tse short version for burning.

All pipelines are mounted in a welded way, but with fiberglass it is easier to keruvate. It is not necessary to clean it, the shards of the reinforcing ball are made of plastic. Polypropylene pipelines are suitable only for heat carriers, as they can hold a temperature no higher than 95 degrees. For more high temperatures, the stench will soften. To that it is better to vicorate for autonomous scorching, in a certain high pressure and it is possible to change the temperature of heat transfer.

The advantage of polypropylene pipes is that they stink 2 times cheaper than metal-plastic ones, do not corrode, and they are also allowed to be monolithic between themselves. Tse allow їх їх at pіdlogu, stіnu аbo pіd stucco.

Metal-plastic pipes

It is necessary to finish the pipes, which are made up of five balls: polyethylene, aluminum foil (2) and glue (2). In the rest of the hour, in fact, the widest ridges of lightness and compactness, building up to a high temperature (up to 95 degrees) and a significant pressure.

The metal-plastic pipe is folded from five balls, which ensure safety: a pipe without a middle, a polyethylene and an aluminum ball, two gluing

Such analogues may have a great internal perimeter, but a small outer diameter, so the stench may be the building's throughput. At the hour of the day, you can win at once two types of fittings: press and compression. Also, during their installation, there will be a rose z'ednannya, which allows a lot of times to pick and choose the pipes. However, for a greater quality, it’s better to beat the pressure fittings, the compression oscillators to start running in a song hour, and they happen to be screwed up.

Aluminum is not in contact with heat transfer fluids, so galvanic corrosion is turned off.

Visnovki

We guessed only the most wide-ranging pipes. Your versatility is not responsible for surprising you. Like a trumpet vibrati for scorching to lie down in the form of the place of that mind, as well as in the form of your skills. For example, it is easier to install polypropylene pipelines, because the stench does not require an expensive construction tool, that stench is much cheaper than steel. Significantly more time to design and select material.

The half-shells of metal-plastic pipes are not the same as those of polypropylene pipes, but the truth is that a wrench will be enough for them. Prote such simplicity can turn into problems for the future. It is best to stagnate in the system of water logs, de no need for an impersonal day.

If you have finances, then give respect to stainless steel. Vaughn will serve you for a long time. Away choice!

How do you blow the best vicorist for scorching? We look at a few of the chimneys that stagnate at once, we override their advances, not enough and try to build on their foundations.

Wash the exploitation

To evaluate the material, a simple set of criteria is needed, why not? Let us describe how pipes are used in the scorching system.

Temperature

Vіdpovіdno to dіyuchih SNiP, the temperature of the water in the zhdnіy іnzhenerії ї komіnіkatsії kommunіkatsії zhitlovo boudinku є 95 z. prote, varto orientate on the boundary value.

Nuance: for the singing conditions (time-consuming dismantling of the nozzle in the elevator, a large number of scargs in the cold near the apartments), the robot of the elevator assembly is practiced by drowning out the blower.

You can’t go near the risers, but water from the heating mains, which is supplied. In this season, the temperature can exceed 100 C, sometimes even more.

At the time of a private house, however, the temperature is controlled by a hairdresser and in the faucet it rarely exceeds 80 C.

vice

Established vice at the scorching system bungalow Trimaetsya in the range of 3.5 - 5 kgf / cm2. The typical vice at the contour of autonomous burning is 1.5 atmospheres.

If the redistribution of the rozrachunkovy vice in an autonomous scorching system is a force majeure, which is more possible with a gross violation of the design standards (say, with an underestimated capacity of the scorching tank and a faulty bleeder valve), then for the central scorch it is all the same.

Varto when launching the ShVIDKO screeds, we take a water hammer with a short-time stripping vise up to 15-25 kgf / cm2. Before that, the effect can be produced by a valve valve at the screw valve, a drop in the valve stem and the other way, not the same as the rіdkіsnі podії.

Mechanical activities

Let's just say: the stench is inevitable. Especially in that mood, if the family has small children.

Vidi pipes

Now, if you understand the exploitation formulated by us, you can try vibrati best trumpets for burning.

Mind you, we can’t see it as an option for pipes made of non-galvanized steel: it’s easy to put a cross on this material. What is being lost?

Galvanized steel

- There is no temperature difference. More precisely, the maximum operating temperature of the pipe is only surrounded by material that is vicorous for sealing threads, and in any case, it is richer than available for water scorching.

- No hydraulic shock, no overturning of the rozrakhankovy vice (even before the supply of 12 atmospheres when testing the trace on the gap) does not bring galvanized steel pipe no shkodi.

- The mechanical virtue of the thing for all praise. So, having stood on the pipe, you can make a thread on it; Ale better, to what you can call it - the need to rewind the locknut on the radiator.

Here it is, we once drank to the bull's-eye. Like a trumpet is better for scorching, lower than that, what does it do for the highest vimogas?

Not so simple.

Є kіlka istotnih nedolіkіv, yakі often zmushyuyut v_dmovitsya v_d steel pipes.

- The price of a running meter is higher, lower for competing solutions. Richer.

- Do-it-yourself installation of a pipeline with a folding configuration will be laborious. We, through the need to hand-pick a great number of cuts.

- In addition, changing the layout of pipes for scorching or heat is the most common way to put a cross on zastosuvanni galvanizing. Laying in a screed, or between lags, pipes with threaded z'ednanny - obviously not the best idea.

Polypropylene

For . The instruction is related not only to their greater importance: polypropylene can have a great coefficient of thermal expansion, which changes to reinforcement.

What is it with the cicavim for us?

- Working temperature of the material is 90 - 95 С.

- Applications vice 20 - 25 kgf/cm2 pipes vitrimyut at 20C. At the maximum operating temperature, the air pressure drops to 7-9 atmospheres (div. also stat.).

- From mechanical engineering, everything is safe: it’s important to break the pipe. Poshkoditi zvarne zadnannya tezh non-trivial task.

To win respect: to add warto to the war low price the kind duzhe shvidky installation.

Sewing polyethylene

Vіd zvichaynogo polyethylene PE-X vіdrіznyaєtsya greater thermostіykіstyu and mekhanіchnuyu mіtsnіstyu.

- The maximum operating temperature in the fallow during the virobnizstva method is 80 - 95C.

- Working vice - 6-12 atmospheres fallow temperature.

- Poshkoditi fittingove z'єdnannya i, tim more, it is practically impossible to open the pipe.

Pipes are supplied in coils up to 200 meters and can achieve a low thermal expansion coefficient, and also stable linear expansion. The main nedolіk — dosit road (about 15 thousand) possession for installation.

In the photo - a pipe made of sewn polyethylene.

Metaloplastik

Without repeating, let's just say: the operating temperature and pressure of most metal-polymer pipes are the same as those of polypropylene. The compression fittings of the pipes can wind a child; however, press-fittings sound on the scorched vicor, which requires a special attachment for the pressing. On the right, in that the compression fittings with union nuts repair the leaks after a few heating cycles and cooling.

Bend the pipe and bend the aluminum core with a small diameter, it is not easy, because the mechanical strength of the metal-polymer on the singed is more difficult.

Visnovki

The stench is obvious.

For centralized scorching systems, the obvious choice is galvanized steel pipes.

What plastic trumpets are the best for scorching in a private booth?

- For high-temperature breeding.

- For laying near water heat best choice become solid, without roses, a pipe made of sewn polyethylene.

How do you know, additional information about the authorities different types You will find pipes in the video attached to the article. Warm winters!