Volume of dry bag. Vaga cement-food screed

Cement-food sums (CPS) are beaten at a rate of 1:3. You can cook such sumish yourself, or you can have it already prepared. Rozchin z ne ї vikoristovuyut when concreted budіvelnih constructions, most often pіdlog, for zvedennya tseglyanyh budіvel, masonry, shaping seams, filling cracks and cracks, zvnіshny design budіvel and іn. TsPS may have a number of advantages: practicality, moisture and weather resistance, monolithicity, seam width and empty, trivial terms of operation.

Yakіsne pokrittya ideally virіvnyuє surface, scho allows vtіlitya in life the most smilіvіshі design solutions and not viklikає problems z navazhkoyu furniture. Sumіshi vykoristovuyut і in the case of the application of water, and even in the case of hanging, the plaster bulges forward looking, saving all its qualities.

| Brand of cement-food sum | M-100 | M-150 | M-200 | M-300 |

| B'astringent component | Portland cement | |||

| Dry sumish color | Syria | |||

| Water content of dry sum (%) | 0,1 | |||

| Packing capacity (kg/m³) | 1550 | 1530 | 1510 | 1355 |

| Vitrata water for mixing for 1 kg sumish (l) | 0,16 | 0,166 | 0,195 | 0,202 |

| Grade for concrete bag looseness (Pk) | 5-9 | 5 - 9 | 5-9 | 5-9 |

| Hour of applicability of the concrete sum for the victoria station (year) | no more than 1 | no more than 1 | no more than 1 | no more than 1 |

| Average thickness of concrete (kg/m³) | 1720 | 1770 | 1780 | 1820 |

| Mitsnist on squeezing concrete with a vіkom of 28 deb (MPa) | 10,0 | 15,0 | 20,0 | 30,0 |

| Thickness of concrete ball (mm) | up to 100 | |||

| Soaking temperature (°C) | 5 - 30 | |||

| Vitrate to the material with a ball thickness of 1 mm (kg/m2) | 1,59 | |||

| Fraction zapovnyuvacha (mm) | 2,5 | |||

| Vaga bear (kg) | 30 | |||

In today's individual everyday life, perlite of tangles and pearlite sand for pistostrumine robots were widely squandered, like stasis like insulators, like in large cottages, and in small cottages.

Designs that avenge pearlite swellings have become popular in the countryside, as a 3-centimeter ball of this size replaces 15 cm of square masonry. Such plaster can be applied without any problems on the surface and hopefully looks more solid, and the walls of the expanded pearlite become fireproof.

Undeservedly, in the Russian life there is victorious sand for piskostruminnyh robots with perlite, wines sip between balls of wall for fire resistance and warmth and sound insulation and economy of budmaterials. Likewise, it is necessary to stop at the ceilings between the tops, with a squeak for the piskostruminnyh robots, to fill the space at the corners between the wooden beams. Zavdyaki to the fact that the perlite sand is sprinkled with free access every now and then, the tree "goes wild".

All refurbished more materials are accessories for any kind of use, stench does not compete one with one, but only supplements. The sand and perlite are natural, so it is safe for health. Boldly use modern eco-friendly materials for the life of your booth.

Cement rozchini, like pure cement, often vicorist for everyday purposes. Vіn mає low vag, in parity with other everyday materials. It is also important for it to be put into the rozakhunka of the masa, which is necessary for laying the mіtsnogo and dovgovіchny foundation. The main indicator of rozrahunka is the volume of the vaga or the pet vaga of cement.

Officials, what to add to the change of cement thickness:

Pitoma vaga cement bag

| Name / brand of cement / sumishi | Pitoma vaga (kg/m3) |

| M 100 | 900 |

| M 150 | 900 |

| M 200 | 900 |

| M 300 | 1100 |

| M 400 | 1100 |

| M 500 | 1100 |

| Food-cement sumish | 1700 |

| Cement-perlite rozchin | 1000 - 1400 |

| Cement-slag rozchin | 1000 - 1400 |

Cement, in the process of transportation, may lose power over time. In such a time, in the wake of the rally, volume of cement set to 1200 kg/m³. Over the years, the material is more compacted, and its thickness will return to normal - close to 1600 - 1500 kg / m³. There are situations, if the cement is filled with water, it becomes too thin, reaching the boundary indicators - 3100 kg / m³. The main factor that contributes to the minimum thickness is the cerozmir of cement stone.

During the control purchase of materials, it is important to give respect to the show. Wanting, unfortunately, to distort the thick of speech, is not easy. And then there is the average indicator, which post-workers can reach - 1300 kg / m³.

Under the hour of mixing the difference, the real possibility of yogo improvement. For whom it is necessary to remember with a great peep (because for the strengthening), then we will exhale in the middle, and in the country with the smallest.

Rozrahunok ob'єmnoї vagi cement for budіvelnyh robіt

When working with everyday sums, use the wrong bastards in materials, they can be judged by productivity and quality of the result. Pitoma vaga cement yak i be-yakogo іnshoy іnshoy іnshoy budіvelny material vyznaєtsya yak: M / V, de M - masa і V - obsyag.

Otrimane spіvvіdnoshnja masi that obyagu, vymiruєtsya in - kg / m³. Point butt rozrahunkіv HC of the brands in the table above.

As you can see from the tables, Pitoma vaga cementu m 500, m 400 and m 300; There is a system for managing the volume of speech in the production. Vaughn helps to set the Bazhan value, vicorist with it see different additives (barium).

Cement-screed screed pidlogi - traditional and time-consuming way to virіvnyat pіdlogi, build a new basis for pіd tile, laminate, carpet.

Familiarization with the technology of organizing a new article in the appli- cations of different countries.

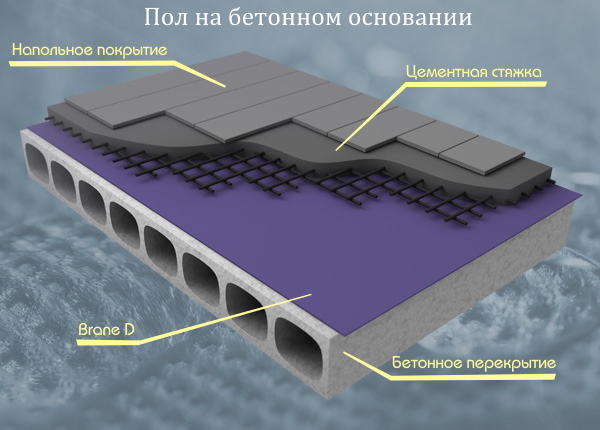

Cement-pasted screed is universal, and it can be fixed on any surfaces: concrete, stone base or base on a stone base.

Warehouse sumishi

For the preparation of a variety, it is rare to add vicarious components: enough of two, guessed from the very name of the method. Standard sizes are prepared in proportion: one part of cement M 300 and 2.5-3 parts of sand. The third binding component is water. To increase the strength cement-food screed retailers recommend adding plasticizers.

IMPORTANT! As a cement-screed, the screed is victorious for organizing underlays in applications with a high intensity of mechanical inflows, the screed is viconated from the cold (reinforced screed).

Picture 1 - Proportions of components for the preparation of cement-food mix and concrete (sizes M 150 and M 200)

With a clear pre-treatment technology, the cement-food screed of the building is vitrified by the pressure from the point tension of approximately 500 N/cm2, communities and occupied with a high intensity of traffic (pishohidna, car zone).

Cement-food screed: vitrata materials

Conducting a fundraiser before purchasing budding materials, ensure that for the organization of a traditional 4-centimeter screed, about 7 bags of cement are needed (it will be enough for a room of 13 m²).

With proportions of 1:3, it is necessary to add more, tobto. 21 bears (wrap, which is often sold less in 50-kilogram bears, in that hour, like cement - in bears of 25 and 50 kg).

Vaga cement-food screed

Before that, how to start a grand commotion at home or in the office, change your mind, so that the application of the construction of the screed should be taken care of: you can choose a more easy option - for example, dry the screed instead of the wet one, or put on the dry fiber screed.

Take, for example, cast-in-place concrete structures in a frame-monolithic life. Takі according to SNiP vitrimyut close to 400 kg / m² yak constant ambition and more 150 kg / m² - yak timchasov. A screed with a thickness of 5 cm will give an additional advantage on a charge of 90 kg / m². Non-leather budova is covered for a brute-force carrying capacity over a maximum of 25%.

Before that, how to proceed to work, rather consult with fahivtsy or, more briefly, - to solidify the plan for staying with the relevant organs of the medical self-regulation.

When rozrahunka vaga screeds important vrakhovuvat, scho itself understanding "vaga" can not be seen one-sidedly: there are two hypotheses - pet vaga and vaga ob'єmna, tobto. Vaga absolutely schіlnogo material that vaga material in yogo zvichnomu stanі. So, for example, according to GOST 8736-77 (Pіsok for budіvіlnyh robіt), the volume of a vaga of 1 m3 is due to mіstiti 1600 kg, and the pet vaga of a pіsku is all according to the same GOST, it can swell in the ranges of 1550 - 1700 kg / m3.

Figure 2 - See screeds as such and methods of organization

additional characteristics

When choosing ready-made sums, it is important to vrakhovuvat such an indicator as a dry stock. Razrіznyayut lung and important cement-food screeds: light weight up to 1500 kg / m, and vzhka - vіd 1500 kg / m and more. Indicative of the thickness of the screed to deposit the minerality of the warehouse itself, as well as indicators of soundproofing and frost resistance.

For apartments and quiet offices, the first group should go.

The thermal conductivity of the warehouse is also to be insured when purchasing materials for organizing the screed. Most importantly, the cement-supplementation may have a coefficient of thermal conductivity of 1.2 W / m per K. If you do not have sufficient temperature to increase the comfortable temperature in the premises, it is recommended that you use additional materials for insulation.

IMPORTANT! For organizing articles in water applications, And also applications, which often contact with the ovnishnim middle, zastosovna so called "floating" screed pidlog (walls and pidloga in the screed with a special gasket), the technology works like that, krіm laying the gasket ball, nothing special in the standard

Vlastuvannya cement-food screed

Preparation stage

Laying the screed can be carried out in any place, the temperature of the base of which does not fall below +5 °C.

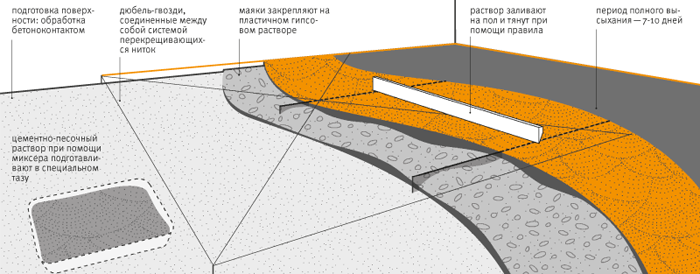

After cleaning the pidlogs from the old pidlogovyh covers and budіvelny smіttya, install the badges of the upper edge of the screed.

For this, use a hydraulic cord and a winding cord. Deyakі fahіvtsі for the accuracy of vimіrіv to draw a control line at a height of 1 m above the horizon (!), And from it, lower the perpendiculars to the height of the screed.

Figure 3 - Placement layout

Tovshchina cement screed it is not guilty to change 5 cm. When laying the screed less than 3 cm lower, it is also undersized.

IMPORTANT! For the repair of screeds, as well as other cracks on the front support, you can use mix M 100.

A ball of waterproofing is laid on the cleaned and prepared base - polyethylene sleeving with a thickness of 8 microns overlapped (15-20 cm each), even if one slit of the slick fabric is not enough to cover all the surface layers. Plivka is guilty to come on the wall: the height of the allowance is determined, moving from the height of the end of the screed - the plume is to blame for the height of the new 5-7 cm.

Figure 4 - Laying a ball of waterproofing

The screed is laid on the lighthouses, it is also possible to vicorist the lighthouse slats or the metal profile with a length of up to 3 m (60 mm by 27 mm).

Beacons are fixed on alabaster with 15-20 cm croque, or on cement-mixing, preparations in proportion: one part of cement M 400 to three parts of sand. As a krіpilny rozchin, it is also possible to vicorate the gypsum plaster summіsh “VOLMA-Shar” (vitrate of materials in this group - per 13 m², one bear is added to the material).

Lighthouses need to be placed in parallel rows with a row of up to 2 m (the length of the row is determined by the old rule, more practical, especially new ones, with a rule of 1.5 m). The extreme lighthouses are set up according to the marks on the walls of the accommodation, and the intermediate ones - quite enough, dorimuyuchis to the rules.

It is necessary to get close to 1.5 years before catching the creaking warehouse at the lighthouses.

Figure 5 - Rechecking the level of the first lighthouses before applying the cement-sand screed to the base of the sublog

The cob is robit

Standing up, the logs are clearly wetted with water.

The screed is laid in smugs on the lighthouses, preparing the cuts in portions.

Screed virivnyuyut rule.

Do not fill another smuga until the pershu is completed (directly works: from a distant corner of the rock to the front doors).

The evenness of the screed is checked with equal.

Upon completion of pouring all the underlays, the screed should be covered with polyethylene screed.

Figure 6 - Razrivnyuvannya applied to the warehouse from the rule

It is necessary to take at least 12 years to the middle stage of the screed.

Let's shine!

In case of faulty pagorbiv on the surface of the screed, or for the use of shortness, it is possible to vicorize a metal spatula and a wooden grater.

It is necessary to have a kidney as a minimum of 12 years.

IMPORTANT! The screed will harden after approximately 28 days.

Figure 7 - Grinding irregularities

It is also recommended to recommend priming the surface of the pads in front of the cob, and deyaki not to shake the ball of waterproofing under the screed, moving, at the time of the flooding of the polyethylene slick, only blocking the natural path to the water inlet.

Repair with a line for 28 days - don’t start manually, before that, how to build a screed in a “wet” way, take a look at an alternative, no less advanced option: organizing a “dry” screed in the premises - already in two days the surface of the screed will be ready to the bitterest extent . !

$ Cement-food screed: food price

Yakscho for wake-up work It is possible to pay maistrams and screed power supplies only when building a screed, then by purchasing materials for a screed, it is often covered with less than the owners of apartments and the premises that are being repaired.

When purchasing budmaterials with your own hands

Slid to pay for the following prices:

- primer for pіdlog Ceresit CT 17 (10 l) - vіd 10.1 $ / pack.;

- lighthouse (3 m) - $0.7 / piece;

- alabaster for fixing lighthouses (20 kg) - $5.2 per bag;

- river dog budive (50 kg) - $ 8.2 / bag;

- cement M 400 (25 kg) - $3 per bag.

Price works for hire

When organizing a screed zavtovshki up to 40 mm :

- in Moscow − 180 rubles/m²

- in Kiev - 45 UAH / m².

Sumish cement and sand is a component of rich varieties and dry sumishes. І pіsok, і cement can vikoristovuvatisya in the warehouse of concrete and masonry, plastering even.

Influx of cement-food summish on the power of the final product

The proportions of cement and sand without intermediary inject into the power of difference or dry sumish. Moreover, the injection of rіznospryatvanovymi, oskolki cement є viscous component, and sand - napovnyuvachy. Vidpovidno, moving part of the cement in the sum:

- Promoting shvidkіst splintering;

- Posilyuє mіtsnіst (up to the singing boundary);

- At some point, there is too much cement to produce to an epic shrinkage and the appearance of cracks;

- In addition, the cement is expensive for the sand, so the zbіlshennya yogo chastki zbіlshuє vartіst ready ї sumisha.

Pisok, at his own hand, will secure the difference:

- plasticity;

- hardness;

- However, it is necessary to carry out the transfer of a part of the sand in a povnyann with cement over reasonable distances to the point of spitting and crying.

Vitrata sumishi per cubic meter

Vitrata of cement-food sums per cubic meter of size (it does not matter for what - for screeding or for molding concrete structures) to fall in proportions that are optimal for this type difference. The variability of the windshield is taken into account all the way to the sum, so that the volume of the ready-made difference is corrected for water.

To give respect, that adding cement to the piss practically does not increase the sum of the sums. Tobto, if you add 300 kg of cement to a cubic meter, you will sum it all up to 1 cubic meter. The reason is that the particles of cement are too small, it is easy to occupy the space between the particles of sand. The same tsim and zumovlyuєtsya uniformity and monolithicity of the bag design.

Let's say that we want to prepare the grade M200 on cement M500. The optimal proportion of such a ratio of 1 to 3 tobto cement is 25%.

The cubic meter of the pipe is about 1400 kg. Based on the fact that we need 25% cement, it will be about 350 kg. Suspension bag of cement-food sumishi will be 1750 kg. The very same vaga of a cubic meter is sumish and is respected by the average.

Don't forget about a cubic meter of dry sum. The volume of the ready-made rozchin will be greater for the rahunok adding water.

How do you add factors to win money?

As a matter of fact, cement-food sumish and є robochiy rozchin (so do not protect water and various modifying additives). Apparently, vitrata sumishi lie ahead of us in front of the scale of work and consumption in retail.

On the vag of cement-food sums are poured:

- proportional to the amount of sand to cement (more often than not to cement, it’s important to sum it up);

- the dominance of the song (the song with great particles will be important for the song of the fractional faction).

Working vitrata of cement-food sumishi is already deposited in a specific type of work and її features. For example, vitrata sumishi on the screed pіdlogi lie down in the comunity of the screed. With more comradeship, you will need more rozchina, obviously, more cement-food sum.

Cement-pasted screed (CPS) is a simple and easy way to implement the state of coverings. For the help of the CPS, it is possible to repair the stone and concrete pads, preparing them before the installation of the final flooring. The middle of the її perevag - dovgovіchnіst, stіykіst to deformation pіd vplivom navantazhen be of any type that low varіst.

At this article, the cement-food screed is visible. You know how to develop materials, prepare designs, install beacons, flood and repair the CPS.

Vaga, terms hardening, various CPS

The only factor that hinders the possibility of cement-food screeding is the great vaga. Yes, wow square meter TsPS comrades 1 cm can reach 15 kg / m 2. With whom, minimal tovshchina cement screed to become 3 cm, so in practice tax cover- laminate or parquet boards) 1 m 2 screeds should not be less than 50 kg. In most cases, the volume of the CPS, which is poured, becomes 5 cm, if you lay a tile on such a screed, then it will be close to 100 kg / m 2.

As a result, the screed for screeding the first layer on top is not fenced, the prote in the bagat-top-surface booths can be beaten up only in the premises, de overlapping, which is carried, it is not less than 300 kg / m 2.

The term, with the help of some kind of dry cement-food screed, can lie down in the middle of the world. So, CPS with a thickness of 40 mm dry for 7 days, and with skin enlargement of 1 cm, 5 additional days are needed to gain muscle mass.

There are two methods of screeding with a screed - making a ready-made sum for the CPS, or preparing a food-cement mix with your own hands. Store bags are classified according to the provisions of GOST No. 28013 into two different types: dry - they are humbled without interruption in the field of everyday life, and wet - they are delivered to the ready-to-wear look. Among the misunderstood sums, which can be optimally combined price / quality, apparently so warehouse like Knauf OP-135, Ceresit CN-69 and Knauf UBV. These are dry sums, which are sold in bears with a volume of 25 kg.

For the sake of respect, the meritorious sum of Knauf-UBO, to the warehouse, I add expanded polystyrene granules. For such a comfortable screed, we take away additional heat-insulating properties, which is especially important when surviving cold weather on the first version of the booth. Vitrata prepared from Knauf-UBO summish is 17.6 kg per 1 m 2, with a screed thickness of 3 cm.

Also, use a warehouse with fiberglass in the house, which will increase the strength and durability of the screed to cracking, which allows you not to break the steel mesh when poured. Zastosuvannya fiberglass CPS allows you to save pennies that hour, in case of glazing of the classic analogue, at the same time the quality of such sumishi is not strongly disturbed in case of sumishes for screeds.

1.1 Warehouse, inventory of materials

To the warehouse, the opening for pouring the screed includes water, sand and Portland cement. It is necessary to vicorate cement for screed class M400, the numerical nomenclature in this case means that after hardening the concrete can be vitrified up to 400 kg / cm2.

The proportions of the components in retail are 4 parts sand per 1 part cement. The amount of water is determined by the amount of water added to the cement - 0.5 liters per skin kilogram. It is the mother’s responsibility to make the preparations for a thick consistency, so that after pouring it does not rise when trying to screed the screed with a wire.

The middle vitrata of cement on a screed with a thickness of 5 cm should be 15 kg / m 2. It is possible to reliably recognize yoga kіlkіst by vykonavshi rozrahunok. We direct the algorithm of such a rozrahunka on the butt of the CPS of a zavtovshka 4 cm and an area of 25 m2:

- Let's find out the volume of the screed by multiplying the square and the torso: 25 * 0.04 \u003d 1 m 3.

- Healthy proportions to the warehouse 4: 1, robimo rozrahunok oblige dermal components: ¼ = 0.2 m3.

- Calculate the actual total for 4 parts of sand: 4 * 0.2 \u003d 0.8 m 3 and one part of cement: 1 * 0.2 \u003d 0.2 m 3.

- From the preliminary data, it is necessary to pay 1 m 3 of sand, which is 1600 kg, and cement - 1300 kg.

- Razrahunok vitrati materials for concrete screeding tasks: cement: 0.2 * 1300 = 260 kg, sand - 0.8 * 1600 = 1280 kg.

In this rank, having shown how much material is needed for pouring the screed. However, it is necessary to buy them with a reserve of 15-20%, as in the process of preparing the cement, the cement sits in the mix.

1.2 What do you need to know the hour of pouring the screed? (video)

2 DSP filling technology

The preparation of black plows before concreting the screed begins with cleaning. It is necessary to prostukat the entire underlay, or the slab of overlap and remove the pieces of concrete, which were opened, which were opened with a rozchin. Then, it is necessary to cover the surface with a primer, in order to increase the adhesion between the base and the DSP. Priming is necessary in two balls, the other is applied after the end of the hour, necessary for the complete hanging of the first ball.

The screed's mark is most conveniently cut out of the zastosuvannya laser level. Attachments are installed at the most important points of the room, and indicators are placed on the walls of the premises and the signs are swaying.

At the next stage, it is necessary to install beacons. Tse directly from the metal profile, with which the screed will be exposed after pouring. We use two types of lighthouses - the primary steel and design, we recommend victorizing the first option, because the work is less laborious for the robot and it will be safer to improve the accuracy of alignment. The width between the lighthouses that are being installed is due to buti 20 cm narrower, the lower width of the vicor rule.

Lighthouses sit on the cake, and you can also twist the pieces of the chain and the mounting pin. The upper edge of the lighthouse is to be found along the line of the upper contour of the screed. Protect that the lighthouse is not guilty of bending over its old days, so that it is necessary to win over a sufficient number of substations.

Dali vykonuetsya zamіshuvannya roschin. Proportions: 1 part cement, 4 parts pistula and 0.5 liters of water per kilogram of cement. It is necessary to start concreting from the largest vіddalenoї vіd doors part of kіmnati - rozchin poured on the basis of the wind and rozrivnyuєtsya beacons for additional rules. In such a rank, pass a lot with an area of \u200b\u200b1-2 m 2.

After 12-15 years, after pouring the surface of the screed, it is necessary to wipe it with cement and sand (1 to 1). To fight for the help of a special mashing machine or a hand tool made of polystyrene. During the grinding process, all the irregularities that were admitted at the pouring stage are visible from the surface. After rubbing the screed, it is necessary to wet it with a wet roller and cover it with glue, it is necessary to repeat the soak every day for 7 days.

Kіlka sіv about reinforcement. It is not necessary to fight if there is a need to compensate for the screed and vibrating tensions that are on the screed, which can be present in the common areas, or in the case of different elastic, slender to deformation bases - lag pads, thermal insulation panels. At times of laying at the screed, a frame with reinforcement, a sieve is taken up by the tension of the veins, changing the risk of deformation to concrete.

If you virіvnyuєte screed in the living room, then, more for everything, there is no real need for reinforcement. As soon as a decision was made to reinforce, it is better to win a road grid with a size of the middle 100 * 100 mm. The sieve is laid on the supports - the pieces were ground or concrete shortcakes so that they were lifted over the base by half the screed, and beacons were placed on top of it. Between the walls of the stone and the edges of the mesh can be buti stand at 5 mm. The process of concreting itself follows standard technology.