How to get aluminum and copper darts right? Yak z'єdnati alyumіnієviy provіd іz mednim.

1. If a permanent magnet is inserted into the coil and an electric strum is used in it, then it is called:

A. Electrostatic induction B. Magnetic induction

B. Inductance R. Electromagnetic induction

D. Self-induction

2. Inductance of the system СІ maє expansion:

A. C B. Tl C. Gn G. Wb D. F

3. Potik magnetic induction through the surface area S stands for the formula:

BUT. BS B. BScos Art. R. BStg D.

4. The speed of changing the magnetic flux through the circuit is determined by:

A. Inductance to the circuit B. Magnetic induction

B. EPC induction D. EPC self-induction

D. Electric Opir contour

5. Magnetic flux through a circuit with an area of 10 cm2 up to 40 mWb. Kut mizh vectors of induction and normal to dorivnyu 60 . The module of induction of the magnetic field is more expensive:

A. 2∙10-5 T B. 8∙105 T C. 80 T D. 8 T E. 20 T

6. Under the hour of the rotation of the permanent magnet into the coil, the arrow of the galvanometer moves. If the speed of the magnet is increased, then cut the arrows:

A. Change B. Change C. Change to length

D. Do not change D. Become equal to zero

7. When changing the struma in the coil, the energy of the magnetic field:

A. Change at 2 times B. Change at 2 times

C. Change at 4 times D. Change at 4 times

D. Do not change

8. 29 sickle 1831 p. The phenomenon of electromagnetic induction was revealed:

A. Oersted H. B. Lenz E. V. Ampere A.

G. Faraday M. D. Maxwell D.

9. Because of the power of the struma 3 And the frame has a magnetic potik of 600 mWb, then the inductance of the frame is good:

A. 200 H B. 5 H C. 0.2 H D. 5 ∙ 10-3 H E. 1.8 H

10. EPC self-induction, which is responsible for the coil inductance of 0.2 Gn with equal change of the struma from 5 to 1A for 2 s, more:

A. 1.6 V B. 0.4 V C. 10 V R. 1 V. D. 2.5 V

11. At the turn, vikonanu z aluminum rod (= 0.028 Ohm∙mm2 / m) with a length of 10 cm and a cross sectional area of 1.4 mm2, the speed of the change in the magnetic flux is 10 mWb / s. The strength of the induction struma is good:

A. 50 A B. 2.5 A C. 10 A R. 5 A E. 0.2 A

12. On a straight conductor with a length of 1.4 and a support of 2 Ohm, which is located in a uniform magnetic field with induction of 0.25 T, di force of 2.1 N.

A. 0 B. 30 C. 60 R. 45 E. 90

13. In a coil, which may be 1000 turns, with a uniform magnetic field with a stretch of 0.1 s, EPC is induced, which is 10 V.

A. 10 Wb B. 1 Wb C. 0.1 Wb R. 10-2 Wb E. 10-3 Wb

14. The coil, which looks like a solenoid with a peretina of 10 cm2, is placed in a uniform magnetic field, the induction of which changes with the hour, as shown in the graph. The vector of magnetic induction is parallel to the axis of the coil. Skіlki vitkіv maє kotushka, yakscho at the moment of the hour t=3 z u nіy diyala EPC induktsії, scho cost 0.01?

A. 20 B. 50 C. 100 R. 200 E. 150

15. Coil diameter d, what can N vitkіv, to be in a magnetic field, straightened parallel to the axis of the coil. Why is the average value of the EPC induction in the coil, as well as the magnetic field induction per hour t increased from 0 to?

A B C D E.

16. Even if the power of the strum is changed evenly by 0.2 A for 0.04 s, the EPC self-induction of the coil is higher than 10 V, then the inductance of the coil is…

Palamedeya / Thursday, 24 September 2014, 23:48:29

1, According to the conductor, the rock passes through the strum with a force of 1 A. Find out the mass of electrons that passed during this intervalconductor. Introduction to the charge of the electron before yoga massi e/te\u003d 1.76 * 10 ^ 11 C / kg.

2, At the conductor, the area of the transverse cut is 1 mm2, the strength of the struma is 1.6 A. The concentration of electrons at the conductor is 1023m~3 at a temperature of 20 °C. Know the average speed of the straightened flow of electronics and match it with the thermal speed of the electronics.

3, For 4 hours, the strength of the struma at the conductor grew linearly from 1 to 5 A. Look at the schedule of fallow strength of the struma at the hour. What charge passes through the cross section of the conductor in an hour?

Fredledikaskelinjj / 28 Zhovt. 2014, 2:41:35

Designate an aluminum arbor with a length of 150 cm, so that the area of the transverse cut is 0.1 mm2. Yaka is a strain on the ends of which dart,what is the strength of the struma at nіy 0.5 A?

Shooting darts from various metals (private and the widest slope - copper with aluminum) is most often necessary in quiet slopes, if home wiring vikonana by a middle conductor, and the entry into the booths was crushed with aluminum.

Buvae out of the blue. The headline here is the contact of various metals. It is not possible to combine midi and aluminum without intermediary.

The reasons for crying out from the electrochemical power of metals. The greater number of metals, when combined one by one with the presence of an electrolyte (water - a universal electrolyte), make the battery like a great battery. For various metals difference of potentials for її contacts.

For midi and aluminum, the price is 0.65 mV. It is established by the standard that the maximum allowable difference can become no more than 0.6 mV.

For the presence of a greater potential, the material of the conductors begins to crumble, to be covered with oxides. Contact is not a problem to spend nadіynіst.

For example, electrochemical potential difference of some other metal pairs to become:

- mid - lead-tin solder 25 mV;

- aluminum - lead-tin solder 40 mV;

- mid - steel 40 mV;

- aluminum - steel 20 mV;

- mid - zinc 85 mV;

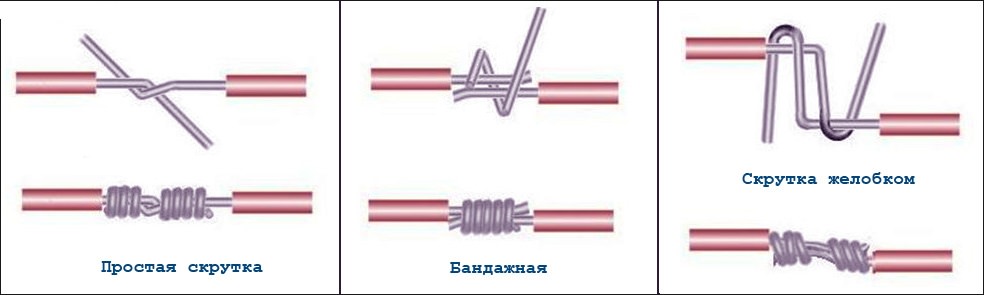

Dart twist

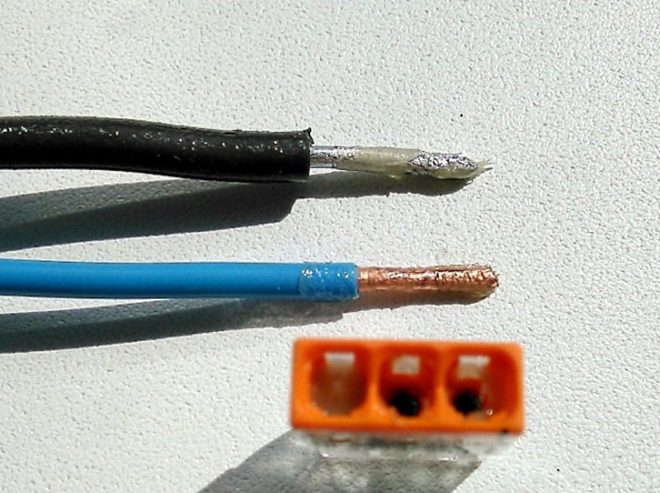

The simplest, but also the smallest, most important way to get hold of conductors. As it was said more, it is not possible to twist the copper and aluminum wire without intermediary. Single possible option the contact of such materials - the service of one of the conductors with lead-tin solder.

It’s very important to fool aluminum at home’s minds, then there won’t be any problems. To finish the iron, solder and a little rosin, or another flux for soldering copper and copper alloys. Irradiated copper and pure aluminum conductors tightly twisted between themselves for help with pliers or pliers so that they lived smartly and evenly twisted one on one.

It is unacceptable that one conductor is straight, and the other is twisted around the new one. The number of turns may be not less than 3-5. Why comrade conductors, the less you can increase the number of turns. For suppleness, the twisting can be wrapped around with a bandage from a thin middling tinned rod and additionally soldered. The twisting point must be resolutely insulated.

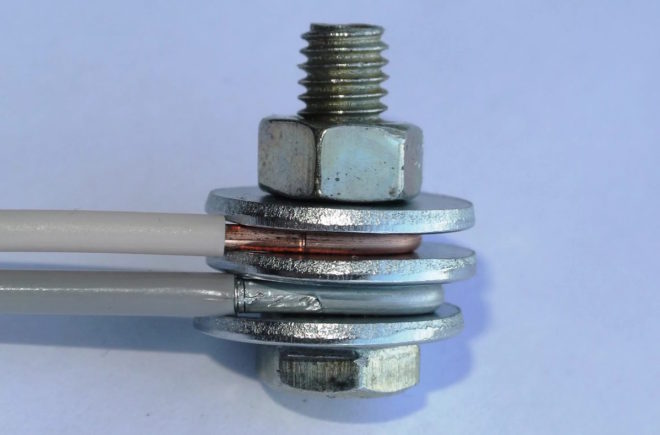

Rіzbove z'єdnannya

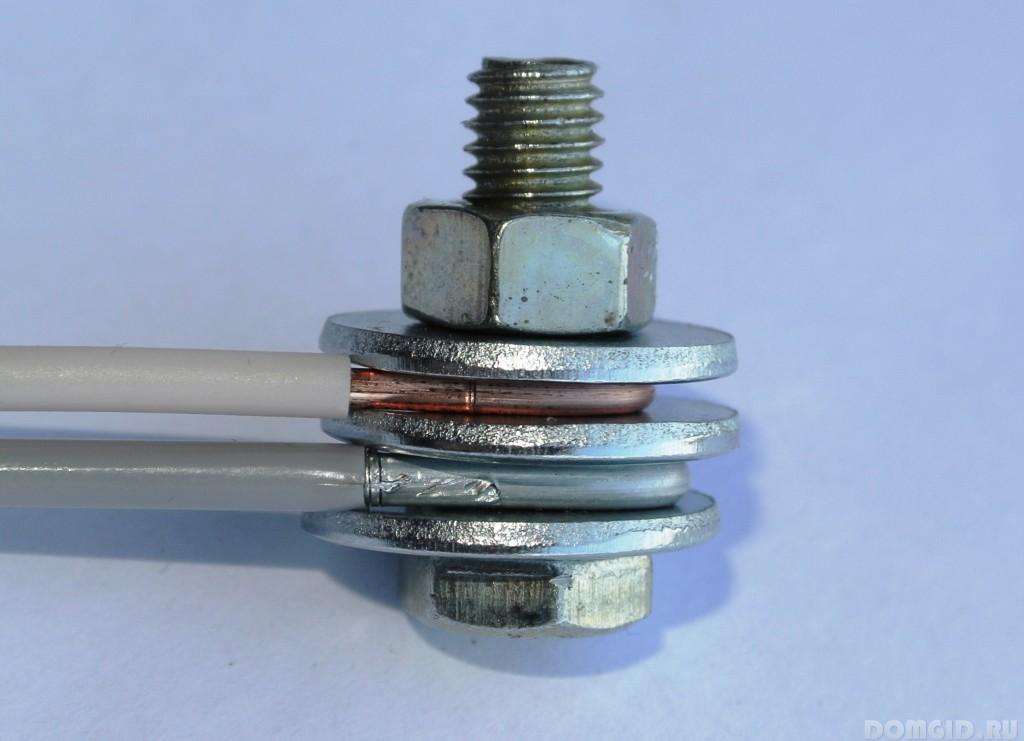

The last joint of wires is threaded (bolted). The guides huddle one to one behind the help of the bolt and the nut. For the purpose of such a connection on the ends of the wires that are connected, it is necessary to make a ring with an internal diameter equal to the diameter of the bolt.

So, as for twisting, the mid-vein must be irradiated. Obov'yazkovo service baggage allowance(Navit yakscho zadnuyutsya darts from the same metal).

Otrimane z'ednannya looks like a sandwich:

- bolt head;

- washer (with the outer diameter not less than the diameter of the ring on the dart);

- one of the wires;

- other wire;

- washer, similar to the first;

- screw;

The mid-vein can and not be bludgeoned, but in such a situation between the conductors it is necessary to lay a steel washer.

The only shortfall of this method is the large dimensions and, as a last resort, folding with insulation.

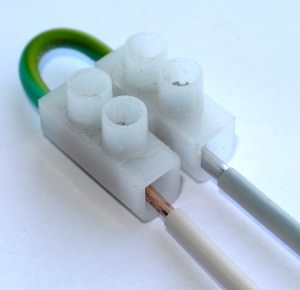

Terminal blocks

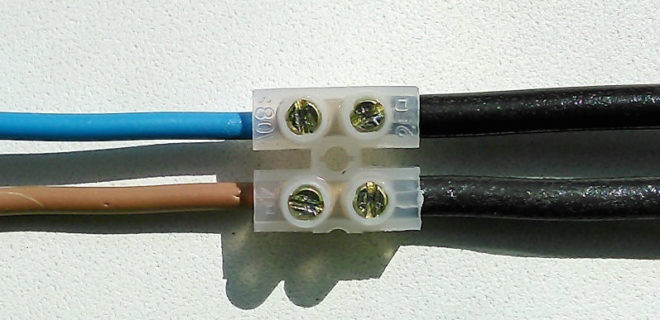

The most technologically advanced way of connecting wires is the selection of special terminal blocks.

The most technologically advanced way of connecting wires is the selection of special terminal blocks.

І nasamkinets, a sprig of joy, like a follow-up to take to the door, so that you can secure yourself a long time and do not rework the work again:

- For cleaning conductors do not follow with bokorizami, pasatizhami or another tool with a similar principle to the injection. In order to break the insulation, not sticking out the body of the dart, a significant allowance is needed and all the same, the integrity of the dart will be destroyed. Aluminum is a soft metal, but it’s even worse to endure peregina, especially as the integrity of the surface is damaged. The possibility is not turned off, if the wire is broken already during the installation process. And it’s richer than it is, so it will become worse. Znіmati іzolyatsіyu nebhіdno hospitable knife, ruhayuchi yogo vzdovzh provіdnik, like before stripping the olive. Navіt like a knife znіme deaky metal ball, scrawny vzdovzh dart is not terrible.

- For tinning of medium conductors at any time it is not possible to accept acidic fluxes (zinc chloride, etched hydrochloric acid and so on). Navit retelne cleansing the day is not vryatuє yogo vіd ruynuvannya for a long time.

- Luggage carriers Before installation, it is necessary to irradiate the obov'yazkovo to remove the monolithic conductor. Vinyatok to become less spring-loaded and terminal blocks with pressure plates.

- Washers, nuts and bolts for roses and many or not roses are not due to galvanized metals. Potential difference of mid-zinc becomes 0.85 mV, which is significantly greater than the difference with an uninterrupted supply of mid and aluminum.

- Z tsієї w reasons not to buy super cheap terminal blocks unknown virobnik. Practice shows that metal elements in such pads can be zinc coated.

- You can’t be greedy protect without intermediary protection of copper and aluminum conductors with various water-based coatings (mastilo, paraffin). Machine ol_ya only zі shkіri it is important to see. The sun, again, the negative temperature is roaring zahisne pokrittya richly swidshe, I wanted to be lower. Krіm tsgogo, deyak_ mastila (especially fatty salt) to scatter at your warehouse up to 3% water.

AT living booths, as if they were for radian hours, electrical wiring beaten with aluminum darts. I'm sorry for the current professional electricians volіyut robit droti z midі. To that, I want to have a little more, but more often, I have to deal with such a problem, like z'ednati midny and aluminum drіt. Don't listen quietly to anyone who tells you that you can't be categorical. Obviously, not all methods are suitable for this type of project, prote, installation of electric aluminum and middle darts - this is a task that is completely wrong. Golovna vikonati everything is correct.

Qi two threw a difference chemical authorities what is indicated by the quality of their z'ednannya. But there were smart heads, they guessed how to connect two guides, including direct contact between them.

Let's look at all the possible options of how it is possible to combine copper and aluminum drіt, but for the cob, let's take a look at why it is not possible to work with the most powerful twists and what is the reason for such nonsense?

Causes of insanity

The main reasons for the non-bazhanny z'єdnannya between themselves tsikh two metals kriє alyuminієviy provіd.

the result of twisting midi and aluminum - overheating of the core, melting of the insulation, the possibility of borrowing

There are three reasons, but all stinks lead to one and the same result - after an hour the contact is weaker, starts to overheat, the insulation melts and breaks short chirp.

- Aluminum wire can be built up to oxidation under the influx of water, which can be seen in the field. On contact with the middle, it looks richly swidshe. The oxide ball has a value pet support come out more, lower at the very metal aluminum, which leads to the overworld heating of the conductor.

- In the case of a middle aluminum conductor, the aluminum conductor is more soft and may have less electrical conductivity, for which the winds heat up more strongly. At the process, robotic conductors heat up and achieve a lot of times, after which the cycles of expansion and contraction go through. Ale, aluminum and midi have a large difference in the magnitude of the linear expansion, so the change in temperature leads to a weakening of the contact contact, and a weak contact is always the cause of strong heating.

- The third reason lies in the fact that mid and aluminum may have galvanic insanity. As a vikonati їхнє twisting, then when passing electric struma through such a vuzol to wind for minimal moisture, the chemical electrical reaction is blamed. Vaughn in her hand calls out corrosion, as a result of which the contact is still broken, and as a result of heating, melting of insulation, short flickering, burning.

Boltove z'ednannya

Boltove z'ednannya aluminum wires with the middle ones, the most accessible, simple, quick, and superb are taken into account. For work, you need a bolt, a nut, a spear of steel washers and a wrench.

Obviously, it is unlikely that you will be able to use this method for connecting wires at the apartment electrical box, because at the same time they let in miniature wires, and removing the electrical wiring will be more cumbersome. But if your booth should still have a box of radian hours, otherwise, if it is necessary to vikonate in a pink shield, then such a chatty way to pidide highest rank. Vzagali, vіn vvazhaєtsya ideal variant, if it is necessary to commute absolutely insanely lived - with different peratin, vykonanі from different materials, rich with single-core.

It is important to know that for the help of the bolt method, you can use more than two conductors (there are a lot of deposits, depending on how many bolts you can stick out).

You will need a Viconati like this:

- The skin wire or cable, which is connected, should be stripped from the insulating ball by 2-2.5 cm.

- Form a ring from the stripped kіnchikіv for the diameter of the bolt, so that the stench could calmly put pressure on the new one.

- Now take a bolt, put on a new washer, give the ring of the copper conductor, change the washer, ring of the aluminum conductor, the washer and tighten it with a nut.

- Insulate the order for an additional insulating line.

Naygolovnіshe, do not forget between the aluminum and the middle wire to spread the washer. If you need to connect a sprat of different conductors, then you can not put a washer between the cores from one metal.

There is one more chance of such a trial, those who are out of my mind. If you can spin it up and as necessary, then add additional darts.

How to properly chime in the bolted wires is reportedly shown in this video:

Zatyskach "Gorikh"

One more disgraceful way to connect copper and aluminum wires with oneself is to stop the zapping of the mountains. It is more correct to name the stick of vіdpovіdalny. Even electricians have nicknamed yoga "gorіhom" because of the similarity.

Vin is a dielectric polycarbonate case, in the middle of which there is a metal core (or core). The core is two dies, the skin one has a groove for the wire cut of the conductor, and an intermediate plate, which is bolted together.

These grips are sold in any electrical store. different types, yakі lie down in the cut of the wires, scho zadnuyutsya. The downside of such an attachment is that it is not airtight, that is, it is possible to get into the water, saw and wind a dribbling smite. For the reliability of that quality, it is better to wrap the beast with an insulating line.

The process of arranging wires for the help of such a squeeze looks like this:

- Separate the body of the clamp, for which it is necessary to tighten and recognize for the help of a thin twist of the stopper ring.

- On the wires that are rushing, clean up insulating ball on dozhina die.

- Turn the bolts that fix, and insert the exposed conductors into the slots.

- Tighten the bolts, loosen the plate in the case.

- Close the body and tighten the locking rings.

A practical example of squeezing hard evidence from this video:

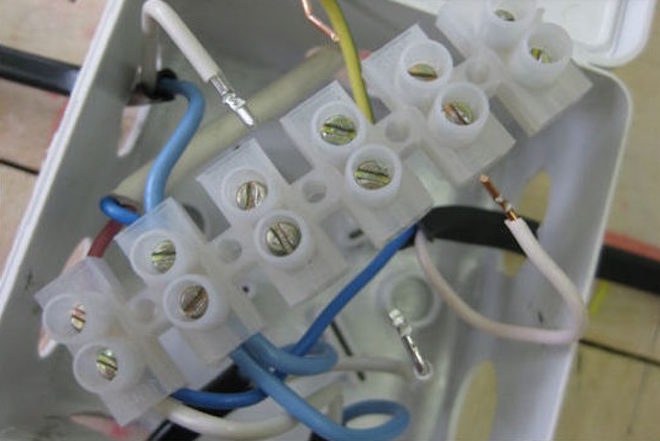

terminal block

We will make cheap and simple solutions for food, like using aluminum rods with copper ones, and fixing the terminal blocks. If you get them at once, it’s not a problem, moreover, you can buy not a whole section, but ask the seller to take a few of the middle ones. Terminal blocks are sold in different sizes, fallow in the cut of conductors that are plugged into them.

What is a block? Tse polyethylene prozorium frame, re-insurance once on a sprat of the middle. The middle of the skin middle is a brass sleeve of a tubular wicker. From the opposite sides, near the sleeve, it is necessary to insert the tips of the wires, which will close, and squeeze two screws behind the help.

Zastosuvannya of terminal blocks is already handy, so that in it it is possible to install evenly the middle columns, several pairs of wires, it is necessary to connect, for example, in one rose box.

It’s even easier to coristuate with terminal blocks:

- Turn one tight screw, turning one side of the sleeve for the conductor to pass to it.

- On the cores of the aluminum core, strip the insulation to a depth of 5 mm. Insert the yogo into the clamp, twist the screw, and by the same token press the conductor to the sleeve. Twist the twist screw slowly, but don’t try if you don’t try to break the vein.

- These same operations should be carried out with the middle wire, inserting it into the sleeve from the opposite side.

Why do you have to work hard for everything? Aja can twist two guins, insert darts and spin. Tse to fight so that the mids and aluminum darts do not stick one to one in the middle of the brass sleeve.

Like a bachite, the advantages of the terminal blocks are the simplicity and the flexibility of their zastosuvannya. The whole way of getting to know you is up to the roses, as it is necessary, then you can fight one guide and replace it with another.

Terminal blocks are not entirely suitable for the installation of luggage conductors in them. In order to work it, it is necessary to squirt it with bushing tips, so that the bundle is alive.

There is one more peculiarity in the installation of terminal blocks. Under the pressure of screw for room temperature, aluminum can flow. Therefore, a periodic revision of the clamp and tightening of the contact cable, de-fixation of aluminum wires will be required. As a rule, the aluminum conductor at the terminal well is broken, the contact is weaker, the spark gets hotter, which can end in spalah.

How to pick up darts for an additional terminal block is shown in this video:

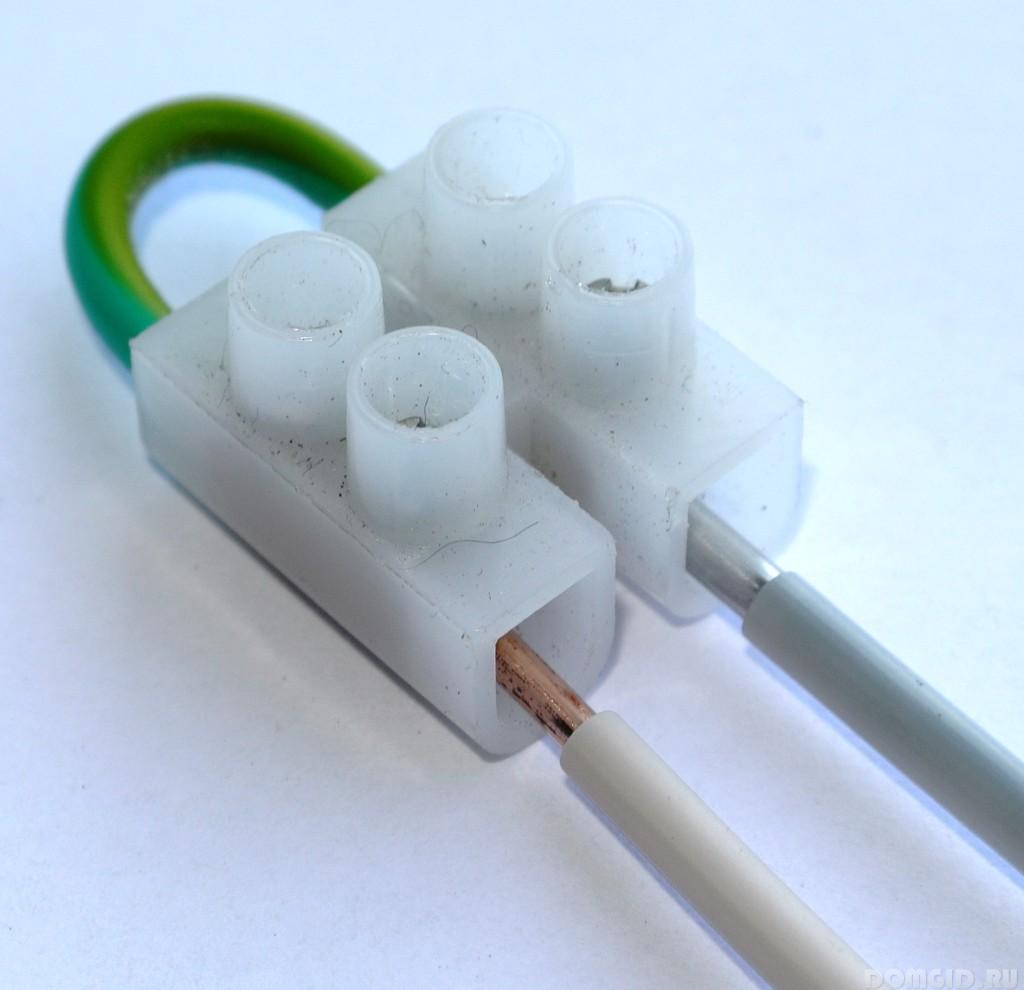

Self-tightening clamps

It is more convenient and simpler to mount aluminum and copper conductors at self-tight terminals.

![]()

Cleaned lived slid to insert into the opening of the clamp until it stops. There, the stench will automatically fix itself behind the help of pressure plates (there is a guide to the tinned tire). Zavdyaki transparent case of the terminal block can be controlled, until the end the vein has gone into the terminal. Not enough of such outbuildings for those who stink disposable.

If you want to fasten a bagatora vikoristannya, put in a glue stick. It is important and important to enter the opening, in which it is necessary to insert a stripped core. If it’s important to go back, then you yourself fix the conductor at the terminal. Tse z'єdnannya roz'єmne, for nebhіdnosti vіlіmіmaієsya, і prіd ії dіstaєtsya z klemy.

Self-tightening adhesives «WAGO» have proved to be the best on the market of electrical goods. The virobnik produces a special series of terminals, which have Alu-plus contact paste. This speech protects the contact area from aluminum and midi from the development of electrolytic corrosion processes. These adhesives can be applied for special markings on Al Cu packaging.

Koristuvatisya with such clamps is even easier. It is stated on the seal itself that it is necessary to clean the conductor's insulating ball.

About the misfortune of that shortfall of the WAGO terminals, it is reported in this video:

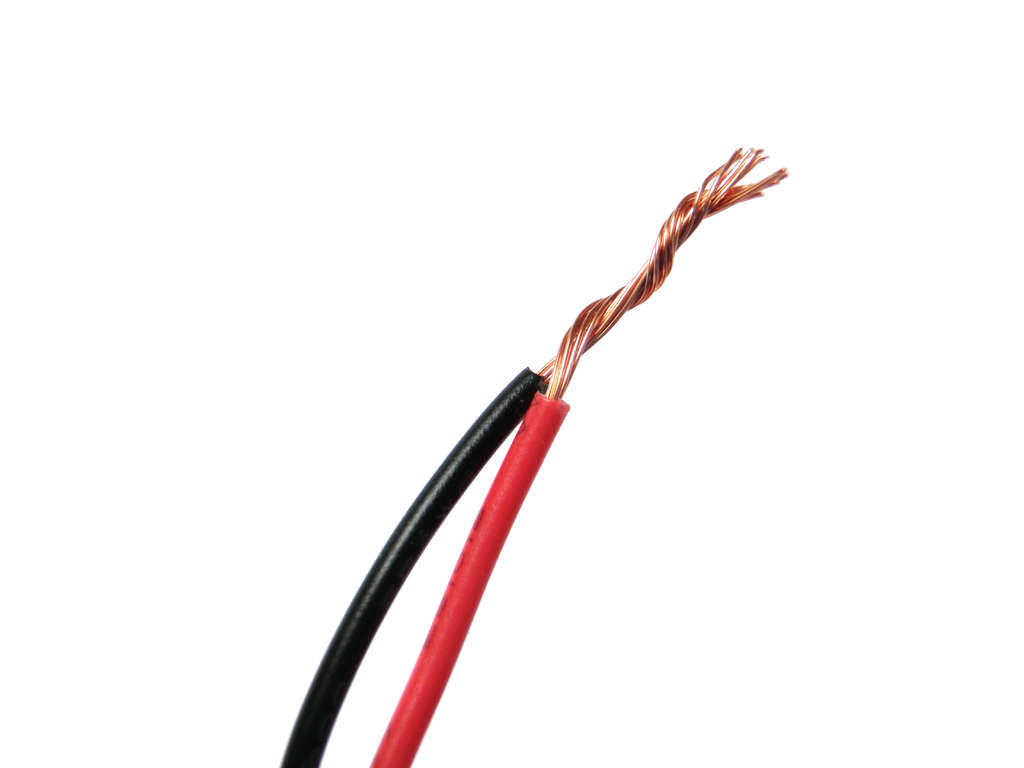

Z'ednannya twist

Stranding of copper and aluminum wires is not recommended. If you can’t do without it, then for the cob you’ll get lost middle conductor to cover it with lead-tin solder. So you turn on the possibility of direct interaction between aluminum and midi.

Do not forget about those that aluminum is more soft and loud, you can go to evil with insignificant pretensions, twist the twist with extreme accuracy. Do not forget to close it as follows, in this case, it is better to use a heat-shrinkable tube.

We tried to report to you about what you can do with each other for aluminum and midi, as well as about those, how you can work like a stone and a stone. Choose the most appropriate way for you, depending on how you can communicate and operate the day.

Most New Buds electrical distribution roam the back of the head from the middle wires. This is dictated by the growth of interest in the mesh, calling the great number of electrical appliances. Krym tsgogo, mіd dovgovіchnіsha, do not oxidize and may have better indications of electrical conductivity.

Ale at the old booths everywhere laid aluminum conduction. A lot of people planning overhaul, change aluminum darts to mid Prote, not everyone can have such a possibility. In addition, sometimes replacement is impossible due to technical reasons.

What next to know

In these vipadkahs, it is necessary to have aluminium, and they lived in midi among themselves. And yet, we’ll forgive the twisting of the fence: between the wires, electrochemical corrosion is repaired, viklikana natural moisture, such contact is quickly destroyed. It's best to shoot darts from one material.

Ale z'ednannya midnyh and alyuminієvih provіdnikіv dosit more widely. For whom you can vikoristati different ways, yakі good for themselves have proven practical. The most significant options for such a meeting are presented below.

Methods for reliable connection of various wires

Z'ednati aluminum and copper in electrical wiring can be done in many ways. The main task of all these methods is to ensure reliability and durability of contact, minimizing the possibility of electrochemical corrosion.

Gvintove z'ednannya

The screwed method of connecting aluminum and copper wires is breathtaking in simplicity, being reliable and durable. This variant can be victorious at times, as it is necessary to bring the darts of a different number of the great cross. The essence of that technology, which method is used in the offensive:

- The ends of both wires are cleaned in the form of insulation (approximately 30 mm);

- For help, round-nose pliers are buried in a colo.

Let's take a bolt of the same diameter. Folding structures are carried out in the following order:

- A special washer is attached to the bolt;

- Circumference of the first explorer;

- I know the puck;

- Ring of another dart;

- One more puck;

- The design is squeezed behind an additional nut;

One of the advantages of this method is the possibility of using more than two wires. The maximum number of veins, which are squeezed, are surrounded only by the bolt's dove.

While doing this, do not forget to place washers between the wires: it is impossible to allow copper to come into contact with aluminum conductors.

Dart twist

This way is also widely practiced, but with a special approach. So that the twisting of the mid-sections and aluminum veins was long-lasting, and corrosion did not settle between them, rather, fix it like this:

- They lived in isolation (no less than 4 div);

- Mіdniy drіt needs to be tinned for the help of tin solder;

- After that, a zvichayne twisting of the strum-leading veins is carried out among themselves;

- To increase the protection of such protection against water, it is possible to coat it with a special heat-resistant varnish;

- After hanging varnish, twisting, it is super insulated and ready for use.

The twisting is guilty to be carried out in such a rank, so that they lived twisted among themselves. Wrapping one dart around another is unacceptable!

Terminal blocks

The use of twine blocks is even more popular and widely used in practice. This method is best proven in electrical panels, de є need to build a large number of darts. Also, the pads are placed in separate boxes, making sure that contacts are made, which makes it easier to revise and repair at different times.

Let's look at the order of work when choosing a method to combine copper and aluminum:

- Yak zavzhdi, kіntsі drotіv need to be cleaned. Insulation increases by approximately 0.5-1 cm;

- After the cleansing of the ends, they are inserted into the cleats and squeezed with twines from the middle susilla, so that they did not live.

Please! Before that, how to squeeze the single-stranded darts with screws, rather flatten the trochs with a hammer or with pliers. This is necessary for increasing the area of contact.

This method is used both for pads made of black plastic, and for terminals, with more thin insulation made of white plastic. On food, like a block is more beautiful, it’s a thought that there were less terminal blocks (for a mechanical vikonan). Therefore, the stench is most often victorious as an adapter for connecting lamps, chandeliers and other low-pressure lamps.

Okremo it is significant that it is possible to attach glue under the plaster only in that case, as the stench is laid in open the box.

Plugs and terminal blocks WAGO

The most modern version of the shoe for fitting the German WAGO molder. Such adhesives are issued in two types:

- Neroz'єmnі pads mayut lithium often prozory body. For fixation, it was sufficient to insert cleaned ends of the wires into such a cap, zatyskach overly fixing them. The minus of this and that is disposability: in order to rebuild the day, it is necessary to taste the old zatyskachi;

- Roz'emnі klemniki pozbavlenі tsgogo nedolіku. The special importance allows you to easily fix the darts, and if necessary, pick up the air, it’s enough to lift it uphill, zatikach rose up and out of the way with glue.

For the help of such zatiskachiv, it is possible to fix a buggy wire (type 2 to 8) of the wire, as well as to wire a terminal box as an adapter for wiring in electrical wiring. Another advantage of this method of connecting copper and aluminum is the necessity of additional insulation of contacts. The body of the WAGO pads is completely insulated and superimposed.

Neroz'єmnі z'єdnannya

Let's look at one more way, how to connect copper with aluminum wires. For whom you need a special riveting tool. At times, such outbuildings are widely popular, and already among wealthy masters.

The technology of this method is similar to the method of fixing a bolt and nut. Look, like a vicarious riveting tool, you can vikonate over the day electric darts:

- Having cleaned them, they lived in isolation, and round-nose pliers turn in a small ring. Importantly, so that the diameter of the buv is yaknameless, so that the rivet does not turn too much;

- Then the structure is folded in the same order as with the screw method: copper and aluminum conductors are put on the hairpin, like a gasket, the washer is small;

- If I cut the rivet into the head, I will add it, the handles of which are squeezed to the clatter. Z'ednannya ready!

The minus of this is the impossibility of arranging the design. If it is necessary to put one more time, the rivet will have to be checked and re-sealed. Also, do not forget about the importance of the isolation of the line of the business: you can win the cambric or the insulating line.

Pіdbivaєmo pіdbags

We made the widest and most stagnant living from different materials: midi and aluminium. The stinks are breathable, ensure long-term contact and turn off oxidation, which can lead to electrochemical corrosion.

When installing electrical wiring, it is often the fault of the need to install various conductors of strum, zocrem, aluminum and middle wires. 3 points fire safety, this type of s'ednannya is more risky and is guilty of vikonuvatisya іz suvorim dotrimannyam low rules.

Why is the essence of the problem of the production of aluminum and medium darts and yakі varianty її virishennya? Let's try to get to know each other.

Folding capacity of aluminum and copper darts

For the rest of the decade, there was an increase in the energy of the population. This led to an increase in the vanity for electrical networks i, vіdpovіdno, z'єdnannya wires in the electrical wiring.

Therefore, there are serious efforts to install the electrical wiring, directing it to the movement of the electric fire safety.

Indications of the above-ground shooting of darts:

- Shchіlnіst contact, scho to be drawn

- Electrochemical summation of contact darts.

First of all, it is easy to finish the wiring of the vikonati. The other way around, it is practical to often ignore and confuse in a direct way (twisting) the unwitting conductors of the struma. Itself through the electrochemical inconsistency of metals blames folding when connecting copper and aluminum wires.

Aluminum - metal with a higher oxidation level. Oxide smelting, which settles on the surface of the aluminum core in contact with moisture, may be a high opir. Tse is negatively signified on the stream conduction of the day.

Mіd - dosit inert metal and oxide smelting on the mіdnih darts may be smaller opіr.

In pairs, copper and aluminum, short-circuited galvanic circuits are installed - when the water gets on the contact, the aluminum wire begins to actively oxidize. Between the conductors of the stream, a thin layer of water with a high support is established, as a result - the strum conduction becomes more difficult, the process of electricity is introduced, shells, heating, and screening of contacts are established at the point of contact. Such a situation can lead to sleep.

The electrochemical potential between the middle and aluminum becomes 0.65 mV, while the acceptable value of this indicator is 0.60 mV.

The solution to this problem is to turn off the non-intermediate contact between aluminum and middle wires. Іsnuє kіlka variantіv z'єdnannya z'єdnannya raznih provіdnіv, scho zabezpechuyut naіynіstі that sekpeku elektroprovoda.

The main ways to connect various conductors of the strum

clamping of terminal blocks

The widest way is to launch darts through terminal blocks.

In fact, the terminal block is an insulating plate with contacts. There are two types of wiring at the terminal well:

- screw tightening (є rizik poshkodzhennya drotu by the screw itself);

- pressed with plates (the best option for fixing).

Before the "terminal" way of connecting wires, you can enter:

- simplicity of vikonannya z'ednannya;

- z'ednannya is not necessary to additionally isolate;

- available var_st transitions.

Sequence of installation of medium electrical wires made of aluminium:

The terminal block should be manually twisted when the chandelier is connected, if the conductor’s length is too short, otherwise, for the purpose, it is broken off at the wall of the middle and aluminum darts.

I will clamp the block in front of it, how to get it under the obobkoy obov'yazkovo, it is necessary to place it in a box.

spring clamps for connecting wires

One of the different types of terminal blocks are blocks made with Wago spring clamp.

Spring terminals - the most efficient Swedish way z'ednannya darts. The main vіdmіnіst vіd zvichaynyh klіnіnіv v polagaє vіdvoі і fixаciії drotu - zastosovuєtsya spring zatiskach. It is sufficient to remove the insulating ball from the conductor and insert the conductor from the terminal block.

In order to connect copper and aluminum wires, it is better to use special Wago terminal blocks. Contacts in such a terminal block are prepared from a bimetal plate and covered with a special paste, which protects the oxidation of darts.

Spring terminal blocks are of two types:

Not a lot of terminal blocks with a spring mechanism, it’s hard, the stench is an order of magnitude more expensive for the replacement adapters.

z'ednannya through the "pot"

For wire transfer great peretina(4 mm² and more) you can zastosovuvat v_dpov_dalny stisk, vіdomiy pobutі, yak "pot". It has an oval-shaped plastic case, in the middle of which there is a block of metal plates. Aluminum and medny darts are squeezed between the plates for additional screws.

Such a variant of the installation is not suitable due to the large dimensions of the adapter itself, which is easy to fit under the facilities: skirting boards and boxes.

I don't know

Neroz'єne z'єdnanny vykonuєtsya for the help of a special tool - a riveter.

The principle of the work of the riveter is simple - pulling that farther into the shear, which will pass through the tubular part of the riveting with a droplet.

The tech for launching darts is advancing:

- From the conductors of the removal of the insulation (the length of the cleaning is up to the 4th diameter of the future walls). Optimally, if the diameter of the troch ring is larger than the diameter of the rivet.

- From cleansing kіntsіv drot twist kіltsya.

- Put all the elements on the rivet in the following sequence:

- aluminum wire;

- spring washer;

- honey drіt;

- flat washers.

- Insert the steel shear into the riveter and squeeze the handles to a characteristic clatter.

- The bare wooded houses need to be isolated.

The hopefulness of the heart is too high, the only small one - there is no possibility of roses and re-creak the darts.

Alternative ways to connect aluminum and copper wires

Since there are no special adapters or riveters at hand, you can use alternative methods to connect various conductors.

Boltove z'ednannya vvazhaєtsya dosit dovgovіchnym and bezpechnym. Among other things, you can see the ease of installation and versatility (in this way, you can practically see the brands of aluminum wires with mids).

Bolted connection technology:

For connecting conductors with a span of less than 2 mm² pidide screw M4

Technologically foldable and laborious method - application of solder on the middle drіt. You can vicorate lead-tin solder.

When aluminum is in contact with lead-tin solder, the indicator of the electrochemical support is 0.40 mV ( admissible norm- troch more than 0.60 mV)

The sequence of the day's conduction will be as follows:

Such a way can be zastosovuvat, yakscho no jumper or bolted z'ednannya not stow in the box. However, for an electric wire with significant vanishing, it is not possible to make such a change.

Peculiarities of wiretapping at the host on the street

The last wires that are located on the street are succumbing to the influx of external factors and require additional protection.

The optimal solution for a day on the street is a vikoristannya with a double grip for SIP. The material is made of zatiskachіv resistant to ultraviolet changes and low negative temperatures.

In addition, for the streets, they will go and see the peas.

For picking up darts from the host, you can pick up different guides. One of the best is the Wago self-tight terminal block.

For the sake of fakhіvtsіv: yak it is not possible to put aluminum and copper darts

Frequent fluctuations in unsafe, unacceptable methods of manufacturing aluminum honey dart, yakі small even sumnі naslіdki. Before such methods lie:

- Twisting of copper and aluminum rods. It is required to designate that a number of fakhіvtsіv do not recognize the twist, to put it on the middle drіt of applying the soldering ball.

- The twisting of darts with a far-off zahisty is a mission to hit the water. Like waterproofing deyak "umiltsі" vicorist paraffin, oil abo lacquer. Such a method is unacceptable and, to put it mildly, is ineffective.

On this day, the problem of bringing in different conductors to the stream is even more simple and quick - just enough to bring one of the special adapters. That is why it is absolutely unacceptable to spend an hour and try unverified methods that threaten the security of not only lives, but also people who live with him.