Winding darts with enamel insulation. Winding electric rods

The principle of work more electrical machines, foundations on the interplay of magnetic fields, which are created behind the auxiliary windings of the coils. Coils - obov'yazkovy detail of generators and transformers, bagatioh radio-electronic attachments.

For their folding vicorist, windings are wired. Rozpovimo about yoga, see that brand, especially that zastosuvannya different types.

Why do you need to know the features of wires for winding

Too many people to rob repair with their own hands, or choose self-contained structures. An electric motor, which often burns, rewinds independently, winds electromagnets (salt) transformers, magnetic antennas and inductance coils for radio-electronic attachments. In case of any damage, it is less than the diameter of the dart and the number of turns (the characteristics can be found in the docs, helpers for the repair or rozrahuvati).

- Ale is often important not only stench, but the th type of drotu, and wine can not be shown. For example, you need a number of turns through those who have chosen a brand with a larger ball of insulation, you can simply not fit into the dimensions of the cat.

- An important type of drotu and for reliability I will add, and navit yogo safety, so choose yogo with insufficient support for insulation, or non-purpose for work at such a temperature, then you can become intermittent zamikannya or prob.

- As soon as I’ve brought it only before I’ll get it out of the way, then another, if you don’t come in safely (grounded, zeroed out), you can be unsafe for life.

Cream of what has been said above, the price of darts is the same electrical characteristics, but different types can be significantly improved. Knowing, you can spare the materials.

Navіscho overpay for provіd, razrahovany pratsyuvati at podvishchenoї tematurі and vologostі for the transformer, at yakom can prіtsyuvati і the PEV brand is expanded.

Classification of darts

Classify darts according to dekilkom criteria.

Conductor material

Tse:

- Midny- Largest width.

- Aluminum- through the larger, lower at the middle of the pet, the support should be placed closer. And in the rest of the hour, the walls expand, because aluminum is cheaper.

- Three alloys support (nichrome thin)- Vykoristovuyut for deyakih outbuildings.

Geometry of the cut

Pererizi darts are round and rectangular. Other victors, if necessary, pass through the conductor of the great struma for conductors from the great area of the cross. For cooling coils, vicorist empty drіt.

Insulation material

vikoristovuyutsya different materials- type of paper and natural fibers, to the fold. Often zastosovuyut sprat balls, for example: papyrus and enamel.

For isolation, it is important as a dielectric power, and mechanical intelligence, and to create a community. There is less than that, more windings can be placed in the coil with a given diameter of the rod.

Marking of darts

The stinks of the dekіlkom are marked with letters and numbers, after the stamps sound, they indicate the diameter of the cut.

Respect. The diameter of the perimeter of the dart is measured along the midi, so you want to recognize yoga, freezing, for example, with a micrometer, and then see the insulation.

At medium darts the first letter P (provided), aluminum is designated AP, for alloys, the support is its own designation. Let's go ahead and identify the insulation, call for the cob letters of the materials and the storage balls and the number of balls. For straight-cut darts, the letter P (rectangular) is put in the kіntsi, then you can go through a hyphen for another number, which lets you know the tipi.

For example PELSHKO - Provid Emal Lacquer Shovk Kapronovy Single, medniy drіt covered with lacquer enamel, which is additionally insulated with one ball of nylon seam. Yakbi bulo two balls, then there would be a letter D (podviyna).

Respect. We are driven by branding, greedy in our country. An imported dart can get out of hand, even to the point that a leather company has its own designation system. Therefore, buying the material of foreign virobniks, it is necessary to change the passport characteristics and choose analogues for the minds of the exploitation.

Paper insulation

Such darts, through low dielectric power, ring out at low-voltage outbuildings, combine with other materials. Paper for these types of zastosovuєtsya special: cable or telephone.

Widely tapped winding wires for paper insulation for oil-filled transformers. They don’t only cool the windings, but they have more opir for probes. Butt marking APB - aluminum winding darts in paper insulation.

Respect. The letter B can mean not only papers, but also bavovnyan yarn, I go to her for characteristics.

Fiber and plaid insulation

For her, there are different types of fibers and slicks: both natural (bavovna, shovk), and synthetic. The stench shows more mechanical tension, the lower windings are wired with paper insulation, and then they are burned according to the tovshchina.

We prepare most of the bagatospheric winding of fibers on the conductor. A possible option if the threads intertwine such a method is stuck for large diameters. Plivka is applied to passing through a bath with a rare insulating material. For the expansion of power, such isolation is combined with enamel, or with paper itself.

The designation of the materials of the windings is as follows:

- asbestos - A;

- arimid - Ar;

- bavovna - B;

- lavsan - L;

- kapron - K;

- trilobal - Kp;

- plastic - P;

- sklo - Z;

- slo z polyefіrom - Сl;

- fluoroplast (teflon) - F;

- natural seam - Sh.

Butt: PBBO darts - winding darts with paper insulation, a ball of settlements with a ball of wound bavovnya yarn.

enamel

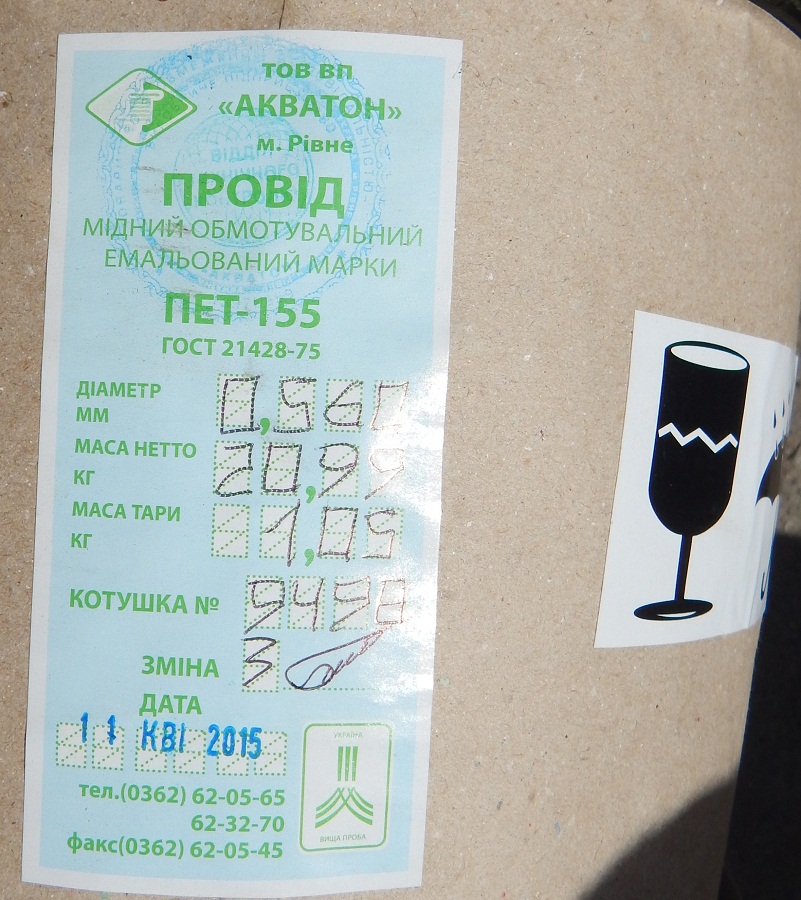

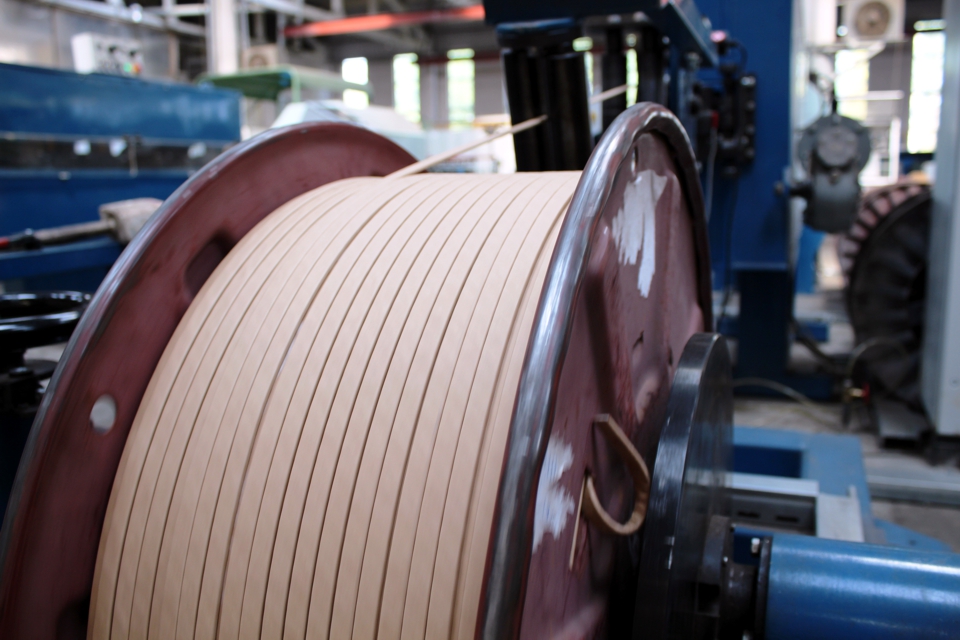

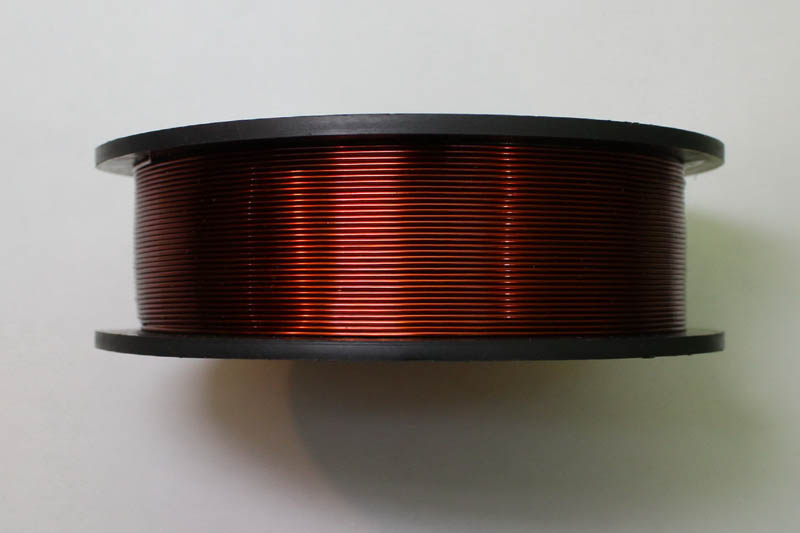

Qi droti vikoristovuyutsya most often. Mayzhe all windings of transformers and inductance coils in electronic attachments are wound with them. The photo on the cob of the article shows the coils of these darts in the factory packaging.

The stench of wide-spread electromechanical fittings lingers. Mayzhe skin is a standard engine, generator, or a contactor, which we are talking about, is not intended for work in special minds, better for everything, mother of a cat, in which winding darts are wound enamel insulation.

The advantage of this kind of insulation is the small size of the hard ball and the simplicity of application. Dosit zanurit provіd in enamel. signify insulating material the letter E, after which the step shows the type of enamel.

- Polyamide - An.

- Viniflex - St.

- Polyamidoftoroplastova - I.

- L - lacquer enamel on olive basis. The widest type. Tse not guarded may on the uvazi stіykіst itself to the infusion of electrical varnish, more precisely retailers, to enter the yogo warehouse. On the right, in that the coils for dodatkovy zakhistu and mechanical fixation of the conductors after winding will leak out with varnish. Emal is not guilty of extortion of authority after the operation has been carried out.

- Polyefircianuraatimide winding to freons - F. Provides windings with enamel insulation of this type vicorist for windings cooled by freons.

- Poliefirna - E.

- Poliefirimidna - EI.

Likewise, darts are vibrated by the maximum temperatures, as if they were vibrating their cover without wasting their powers. Divide them into groups (indexes) - 105, 120, 130, 155, 180, 200, 220 and more likely.

Some other features of isolation can be shown in marking

Crimean type of material for insulation and number of balls, additionally in marking can be specified:

- Those who won are strong - U.

- Witonchen - I.

- Covered with a ball of additional varnish on the surface of L.

Winding wire for high frequencies

- Crim of standard single-core darts for coils, which work at high frequencies, vicorist special darts - litsendrati.

- On the right, in that the high-frequency streams pass less than the surface of the conductor. Opіr at times, there is no way to deposit in the area of the conductor's perimeter, as in the case of the old perimeter.

- In order to maximize the її, the winding wire is wrapped with a rich core - from thin bundles, with a diameter of a fraction of a millimeter, conductors. The splitting is carried out in a special way. These darts are designated by the letter L.

Pererakhuemo the most wide brands of such darts:

- LEP and LEL- a bundle of conductors without additional insulation.

- LESHO and LESHD- wrapped with a seam in one and two balls.

- LEPKO- with fibrous kapron coating.

Respect. Clean up the insulation from such wires in a mechanical way, through thin wires it’s important, so before їх ludinnyam for soldering the vicorist, special pickling warehouses are used. Only LEP and LEPKO can be soldered immediately - even insulation is seen when heated with a soldering iron tip.

How to choose wire for winding or coil

Before speech, hand-wound winding is distinguished by a special quality (with the highest qualifications of practitioners).

Peretin and mark of drotu in the windings are indicated in the passport in the form, often given are written on the extension itself. If the document is spent, then there are a few ways to recognize data.

- For electric motors, contactors, inductance coils and throttles, it is easy to know the characteristics of the drivers - only if you don’t get a copy of the cordon virobnitstv, or we’ll erase the markings.

- Just like the voltages on the transformer windings are both tight, then the methods are clumsy. The instruction, as it were, is clumsy - it is necessary to freeze the resection of the core and literally pierce the formulas. It is even simpler, electromagnets and inductance coils and chokes are rozrakhovuyutsya.

- If it is impossible to put two methods in front, then simply when sorting out the burnt or broken winding, the diameter is measured and the number of turns is changed. Obviously, take a lot of time for a great number of turns, or you can win the winding with the winder.

Knowing the cut and the number of turns, it is necessary to carry out, with the necessary insulation, with an eye on all the officials. The need for marking can be determined by visually recognizing the insulation.

But it is necessary to protect other officials. So, for windings that are wrapped around tightly, do not go with enamel insulation - the electrical power will be ruined at temperatures above 180 degrees Celsius, and it will simply melt.

How to practice in the minds increased water content, then do not block the fibrous winding through її hygroscopicity. Clean up the exploitation of the wires are reported on the passports.

Porada. If the problem is caused by the purchase of a rod of the required diameter, then it is possible to wind the winding with two or three connections in parallel, moreover, the amount of the area of \u200b\u200bthe span (you can find out in the windings) will reach the required size. Well, it’s great to be able to fit into the rosemary of the cat.

Let's be glad, as our article helped you with repairs other outbuildings otherwise, in an independent design, that folding. It’s bad to know that we just ruined the knowledge in electrical engineering and now you know what the winding wires are winding with paper insulation like PEV.

Appointment winding electric darts polygaє at their choice when preparing the windings of transformers, devices, electrical machines and accessories. At tsikh windings of electrical appliances, there are soundless windings.

Winding darts on the vіdmіnu vіd installation ta installation wires characterize by the diameter of the veins, and not by the flatness of their peretina. That's a lot of stamps winding wires may have lived even of a small diameter, their comrade's insulating sphere was tiny.

There are about 100 brands of wires of small diameter, and all the beginnings of the development of technologies for the production of especially thin wire and the creation of progressive electrical insulating materials.

For a thriving hour, the winding wires were prepared only from midi. Also, for these purposes, zastosovuyt aluminum, as well as alloys with a significant pet electrical support. Vikoristannya aluminum allows you to save copper - a scarce material, and the accumulation of alloys with a great support allows to increase the heat resistance of the winding wires.

Winding rods are classified in the fallow type in the form of insulation. , at the same time looking at the material, from which the strum conductors were prepared:

With enamel, sklovoloknisty or fibrous insulation;

- with enamel-fibrous (combined) insulation;

- with plaid insulation.

When preparing winding wires, vicorous lacquers (for insulation of wires) and lavsan, bavovny, seam threads (for insulation lived in the weaving and braiding of windings).

Winding darts are designated according to the same principle as assembly darts- for additional help, indicate the material from which the core or insulation was prepared.

Let's talk about the main literal meanings, With the help of those, specify the brand of winding wires. We designate the material from which the winding wires were prepared. On the first place, put the letter P on the marks of all medium darts and at the same time signify: “provid”, yoga was prepared from the midi. In order to make the middle wires with enamel insulation in aluminium, for example, mark the letter A, for example: PEV - conductor with the middle conductors; PEVA - conductor with aluminum conductors.

Let's talk about the main literal meanings, With the help of those, specify the brand of winding wires. We designate the material from which the winding wires were prepared. On the first place, put the letter P on the marks of all medium darts and at the same time signify: “provid”, yoga was prepared from the midi. In order to make the middle wires with enamel insulation in aluminium, for example, mark the letter A, for example: PEV - conductor with the middle conductors; PEVA - conductor with aluminum conductors.

For marking wires made of alloys with a great support, the letters are indicated: HX - nichrome, K - constantan, M - manganin; if it is necessary to signify that the drіt is soft (burned), then after the letter M or K put the letter M; for the purpose, which is hard, put the letter T. The axis is applied: PEMM - dry, yoga vein is prepared from soft manganin; PEMT - provіd, yoga vein made from solid manganin drotu; at the annex there are no other wires.

Letters for marking the type of insulation for winding darts:

EB - high-quality enamel on a polyvinyl acetate base;

EL - enamel on olive basis;

EM - high-quality enamel on a polyvinylformal base;

ELR - high-quality enamel on a polyamide-resol base;

Ш - natural seam;

L - lavsan;

C - fiberglass;

Pro - one ball winding;

B - bavovnyan yarn;

D - two winding balls;

ShK - capron.

It is clearly marked with another letter P, plaid insulation is marked, for example: PPF - insulation with fluoroplast.

When specifying for those wire grades made from combined insulation, the letters are in the order of the passage of the balls in the insulation from the inner ball to the outer ball, for example:

Apply (how to decipher the marks of winding darts):

PELR - midline wire with insulation from high-quality enamel on a polyamide-resol base; PEVKM - wired with soft constantan dart with insulation from high-quality enamel on a polyvinyl acetate basis;

Winding wires are wires that are used for the preparation of windings of electrical machines, devices and accessories. Significant number of winding wires is also used in the manufacture of accessories, in various radio-technical outbuildings, in TV sets, in aviation and space technology, too.

Winding darts can be classified:

on zastosovuvanih conductor materials: copper, aluminium, and three alloys support. A small part of the wires is released from conductors from bimetals, expensive metals and special alloys, superconducting wires;

for types of insulation: winding darts with enamel insulation, or enameled darts; winding darts with fibrous or combined enamel-fibrous insulation, including fiberglass and paper; winding darts plastic insulation, including plivkova. In addition, winding darts with succulent glass and scrambler insulation are let out in the room;

for the value of working temperature (heating capacity class). The largest group of winding wires and enameled wires, which may be the source of the warp: more thin insulation allows for a greater groove filling factor electrical machines and devices, increase their exhaustion or reduce the overall dimensions of electrical appliances for the conservation of essential parameters. Also, from the point of view of minds, the choice of enameling darts is less laborious and is coupled with wires, the insulation of which is superimposed on the dreat, for example, by the winding method. Therefore, during the transition to the release of enameled wires, the productivity of cable factories increases. An important trend in the production of enameled wires is more important than the increase in the production of thinnest wires, the improvement of the microminiaturization of radioelectronic equipment and computational equipment. The number of enameled darts is expanding at the same time special recognition, dart cores with an additional adhesive ball, which are used for winding coils of winding systems of televisions, as well as for windings of electric motors without zastosuvannya rozchinnikov. important momentє also the transition to victorious enamel varnishes with less toxic retailers and the introduction of enamel technology from the melting of resin without zastosuvannia of retailers. Today, the choice of winding wires requires specialists from cable factories to obtain deep knowledge from the gallery of possession of that technology, methods of testing, how to install conductors and electrical insulation materials. The practicality of the winding wires at the warehouse of the bins is rich in what is determined by the correctness of their choice from the point of view of the minds and modes of operation, the design of the bin, and also to lie in the technology of preparing the bin itself. The term of service of one and the same door at the warehouse of different types can vary in a few times, so the operating temperature is close. Basic conductor material, which is victorious for the selection of winding wires, є mid. According to the electrical conductivity, copper outweighs all other materials, with a little credit, which allows you to secure the minimum dimensions of the windings of electrical machines, devices and accessories. Vіdpovіdno to GOST 859–78 mіd for a chemical warehouse is subdivided into a sprat of stamps. In the cable industry, there is less than mid-high purity grades not lower than Ml, M00k, M0k, M0ku, M0ob, M0b, M1k, M1b, M1u. The M1f grade copper does not stagnate due to the addition of phosphorus (0.012 ... 0.06%), which reduces the electrical conductivity. In addition, for winding wires, it is not possible to use vicoristan copper of the M1r brand, deoxidized with phosphorus and contain iogo in an amount of 0.002 ... 0.012%, although such copper can be vicorated for other types of cable products, for example, stitches. Change midi at a time from srіblom in these brands midi to become 99.9 ... 99.99%. Indexes for grades may have the following meanings: k, ku - cathode copper, b - acid-free, y - cathode remelted, p i f - acidified. The numbers 00.0 and 1 are used instead of midi, and the largest inmist midi may be M00k and M006. Domishki give an unfriendly injection on the mechanical

the electrical power of midi, to that midi from the house is higher than 0.1% in cable vibrations. The best parameters from the point of view of the stagnation of the winding wires, and in the first line of the enamelled, may be without kisneva mid, may be vilna in the place of kisnya. It overturns the ultimate plasticity and secures the removal of droth with a thinner surface.

Appointment and classification of lacquers.

Electrically insulating varnishes, which are used for enameling droth, are varieties of high molecular weight smelting compounds or low molecular weight reactive oligomers in organic volatile soils. When the enamel lacquer is heated in the enamel oven, the molecular weight of the smelting speeches increases more, and the maker is steamed, as a result of which hard enamel smelting is set on the dart. Different synthetic resins, as well as deaks of dewy olives, are like a melting pot. Retailers of smelting materials for that other retailer can have a different concentration depending on the diversity of the lacquer base. Enamel varnishes can be synthetic or oil-tar based. Synthetic lacquers are used on darts with more iron and heat resistance of enamel plating, which is why it stinks of practical use of lacquers on an oil-tar base, in which, before that, there are state-deficient olive olis. So, about 95% of the used enameled darts are made from the overdose of synthetic lacquers.

Zagalni vimogi to enamel varnishes

The last representative of polyvinyl acetal lacquers, which is very common in the veterinary practice, is PL 941 lacquer, or metalvin. Varnish metalvin - ceroxins of polyvinylformal and phenolformaldehyde resins at a mass ratio of 2: 1 with the addition of a stabilizer - trietanolamine. The smelting for its electrical insulation and mechanical powers does not break down in the smelting of the vinflex lacquer, but I turn the rest for the stability to the influx of organic retailers and water. Behind the cordon, varnishes for enameling dart on the basis of polyvinylformal resins known as formex, formvar, toshcho. Colored lacquers are treated with a warehouse of modifying agents, as well as often with the help of a warehouse of the main resin.

Varnishes for wires with a temperature index of 105 ºС

In the yakost insulation covers enamel darts are the most widely used coatings based on polyvinyl acetal lacquers. Polyvinyl acetals are products of interaction between polyvinyl alcohol and various aldehydes (formaldehyde, acetaldehyde, butyric aldehyde, etc.). Polyvinyl acetals are called polivinylformals, polyvinylformals, polyvinylbutyrals, etc. Polyvinyl acetals are called polyvinyl formals, polyvinyl acetals, etc. The most widely used polyvinyl acetate lacquer in venerable practice is cell lacquer PL 931, or vinflex. Vin is a variety of polyvinylformalletyl and resole phenolformaldehyde resins in the sum of technical chlorobenzene and ethyl cellosolve in a 1:1 ratio.

Varnishes for wires with a temperature index of 120 ºС

Polyurethane varnishes are applied for enameling darts with a temperature index of 120 ºС. Polyurethane is a product of interchange of diisocyanates with half-shells, which can cover two or more hydroxide groups. Vytchiznyany varnish UR 973 is used in combination with monophenylurethane, phenolic and polyester resins with the addition of polyvinyl acetal resin. Small additions of polyvinylformaletital to improve the appearance of the varnish and increase the brightness of the surface. In the remaining hour, the polyurethane lacquer of the brand UP 9119 can be broken down in the remaining hour to enamel small-diameter darts over the lacquer UR 973. Adding 0.3% zinc naphthenate to the lacquer will speed up the process of hardening in the process of thermal processing of the coating on the darts. Coating based on UR 9119 lacquer can improve anti-slip resistance.

Varnishes for wires with a temperature index of 130...180 ºС

For the production of enameled wires with ТІ 130, 155 and 180, lacquers on a polyefirnіy, polyefіrіmіdnіy, polyеfіrcіanurаtimіdnіy and polyеfіrіramіdіmіdnіy bases are vicorated. Tsya group of lakiv nіnі є the main one like our country, and there. At vіtchiznyanіy praktitsі vikoristovuyutsya two polіefіrnі varnishes scho rozrіznyayutsya method for obsession, PE 939. PU 943A i Nezvazhayuchi on vіdnosno temple nagrіvostіykіst, іzolyatsіya on osnovі polіefіrnih lakіv Got spetsifіchny nedolіk - znizhenu stіykіst to thermal shock, yak polyagaє in fact scho at roztyaguvannі abo Whip droti to the singing world sharply for a short time after a high temperature rise can lead to cracking of the insulation. With the method of increasing the resistance of enameled wires with polyester insulation to thermal shocks with an one-hour increase in resistance to heating of vicorous, modified polyefire varnishes are applied. Modified polyester lacquers were expanded to increase resistance to heating of insulation of enameled wires, mechanical resistance to abrasion, resistance to thermal shock and other types of wear. For the modification of polyether resins, vicorous acids are used. Heat resistance of insulation based on polyether urate varnishes to become 155...180 ºС. The main types of modified polyester lacquers are polyefirimide and polyefircyanurathimide. Polyefirimidi - all polymers that can be heated, that can be avenged by imitations, ethereal groups and aromatic cycles. In domestic practice, polyephirimide lacquer has a brand of PE 955 and is a product that is used with dimethyl terephthalate, ethylene glycol, glycerin, trimelite anhydride and diaminodiphenylmethane. PE 999 polyethercyanurate lacquer is a zebra polyethercyanurate amide resin based on dimethyl terephthalate, ethylene glycol, TGEIC, trimelite anhydride and 4,4 diaminodiphenone methane in the sum of tricresol and xylene. Vitchiznyany varnish ID 9142 looks like varnish PE 999 by moving in the middle of the imitation part. Coating on the basis of lacquer ID 9142 can improve resistance to abrasion, adhesion, temperature of insulation penetration, resistance to thermal shock. For the production of PEVTL 155 enamel darts, polyurethane lacquer UR 155K, which can resist up to 28 ... 32% of the non-volatile part, in the composition of cresol, solvent, xylene, with a viscosity of 25 ... 50 the chemical basis of such polyimide of alicyclic budov. The penetrating voltage becomes 8000/10000 V. As a retailer for these varnishes, cresol, solvent, xylene are used. Їх viscosity according to ВЗ 246 at 20 ºС: 120...106 s (for ПІ 180FA) and 35...45 s (for ПІ 180ФБ). Provid PET 180 can be carried to free-standing darts. Process Іntensifіkatsіya vigotovlennya emalovanih provodіv at vikoristannі visokoshvidkіsnih emal agregatіv zazhadala rozrobki novih emal lakіv scho volodіyut spetsifіchnimi vlastivostyami: roztіkalnіstyu Garnier, Neznachny vmіstom nizkomolekulyarnih fragmentіv plіvkoutvoryuyuchoї resin SSMSC vigoryayut at temperatures pіdvischenih i emaluvannya etc. Elisvan 155 (155t) І ПІ 180 ФМ FOR EMALYUVENNA Warning on Emal aggregates З Vd> 50. Zvitchy way of removing Polііmіdіv alkikkіniy Budovi є Polіcondersatsey, if in the result of a matter of dialing diranhydrides i dіamіnіv SMIFOVYE HAPPY POLIMIKOVOTOVATE, ZAKOY POLIMID, Yak Potіm moreover, the temperature regime of the thermal processing of the forpolymers is hard - from 80...100 to 300...350 ºС. Apparently, among the polymeric slurry materials, polyamide slurry occupies a special place with high thermal, physical and mechanical power, dielectric characteristics, chemical stability.

Varnishes for wires with temperature index 200...240 ºС

For wires, for a long time, they are operated at a temperature of 200 ... 220 ºС, lacquers on a polyamide base are used. Polyamidimides are polymers, yak crim amide groups to avenge amide aromatic cycles. Vytchiznyany polyamide lacquer AT 9113 is a variety of polyamidimide in the sum of N methyl 2 pirolidon with stone carbon solvent at a ratio of 9: 1; in the varnishes PAI 200A, PAI 200B, the composition of the retailers N methylpyrolidone, xylene is vicorated. Crimean high heating polyamide lacquers are safe from mechanical coatings, which outweigh the coatings on the basis of polyvinyl acetal resin. Polyimide varnishes are applied for insulation of wires, which are used for a long time at 220...240 ºС. In the process of saving for room temperature, the viscosity of polyamide varnishes decreases. At elevated temperatures, on the other hand, gelatinization through cyclization and a stronger increase in viscosity are possible. The selection of polyamide varnishes is connected with the choice of expensive and scarce materials. The productivity of work when enameled with polyimide varnishes decreases, which also leads to more expensive drota. Therefore, the zastosuvanya of darts from polyimide insulation is surrounded. In addition, it is worth noting that enamel plating based on polyamides may have less mechanical strength for erasing, lowering, zokrema, plating based on polyethers.