Yak z'єdnati alyumіnієviy provіd іz mednim. Why can't you put copper and aluminum darts in?

Aluminum wiring in our days is more common. Vaughn perebuvaya most importantly at the houses of the Radyansk spore, as if to establish a greater part of the housing stock of our country. And now, the new electrical wiring is built up already in the middle wires. That is why you want more than that, but you often have to wake up aluminum darts. It’s possible to stop, but it’s necessary to work correctly and correctly. How robiti you can recognize z tsієї statti.

Copper and aluminum can be different Chemical power, yakі are signified as їх з'єднання. Upon contact with the middle, aluminum shvidko is oxidized under the influx of water, which is near the surface. Also, qi metal may be different linear expansion for temperature changes. Through this, in the midst of the meeting, midi with aluminium, the filthy contact is established and, apparently, the great transitional opir appears. That's why it starts to feel warm, tobto. The place of the day is heated, then the insulation will melt and may become an NP. It’s already nasty and it’s necessary to work at home in such a way that it didn’t happen.

From the foregoing, you can make such visnovkas that you need to turn on for a yakisny z'ednannya:

- direct contact between midi and aluminum;

- hit again in the middle of the day.

Іsnuє kіlka ways z'єdnannya:

- for an additional bolt with a nut and washers;

- for the help of the screw locks of ZVI;

- for the help of modern universal clamps;

- for help twisting through a ball of neutral speech;

- for the help of a terminal of the "Gorikh" type.

Let's take a closer look at the report of the skin method of making the day aluminum wires.

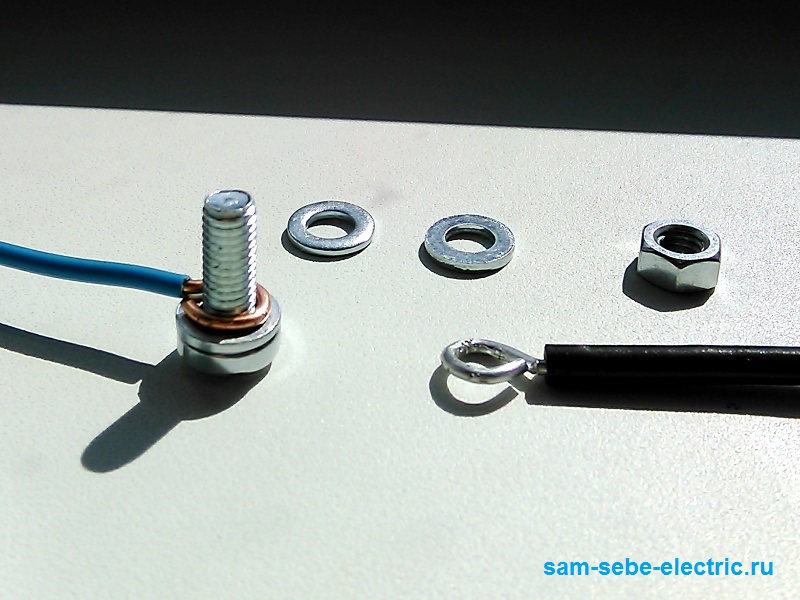

1. For an additional bolt with a nut and washers.

Tsey method of treatment is even simpler and more accessible for the skin. You need a bolt, a nut, a sprat of washers, or for a bunch of lock washers. Here we do it like this:

- cleaned up lived approximately 2 cm;

- robimo kіltsya z drotіv bolt diameter;

- take a bolt, put on a new washer, then the copper ring lived, I changed the washer, the aluminum ring lived, the washer and everything is tightened with a nut.

- all connections are insulated with electrical tape.

See photo instructions:

Don't forget to put an intermediate washer between the middle and the aluminum.

Kіlkіst lived, scho zadnuyutsya, maybe be different. Vono is surrounded by a dozhinoy bolt. Wire from one metal can be connected without intermediate washers. Varto indicates that this method is good for single-core (hard) cables.

The downsides of such an arrangement are its bulkiness, which can be easily accommodated.

Also, it is often necessary to have enough aluminum wires to wash from the distribution box, which is insufficient for this method. Then you have to stop zastosovuvati іnshi options zadnannya drotіv.

Bagato who cares about the bolting of the middle ones with aluminum wires is the best. However, my practice has a proliferative depression. Look at the photo below. Here you can clearly see how everything has oxidized and the insulation has melted heavily. Tsomu poednannyu zі slіv lord is only two fates.

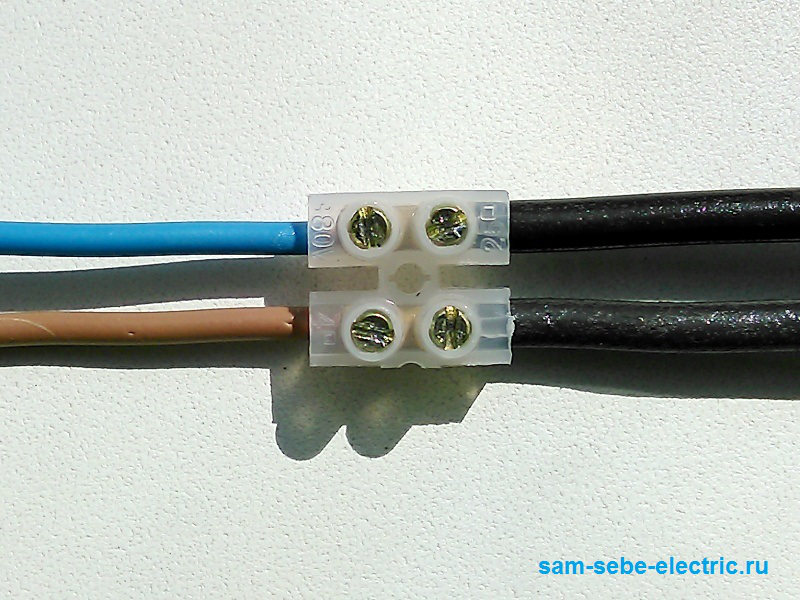

2. For the help of the screw locks ZVI.

Gvintovі zvіskі ZVІ sogodnі razhenіnі. Three additional lamps and chandeliers are connected to them.

Here we do it like this:

- we clean the darts halfway through the glue;

- it is inserted from the outer sides of the terminal block;

- tighten the bolts.

See photo instructions:

If you put the darts in the zatskach, then try to make sure that the mids and aluminums do not live one by one.

Here, don’t overdo it and don’t smash with a bolt the full aluminum drіt, the shards of wine are soft. There were fluctuations, if you want to twist it more and more, and as a result, it turned out that they simply flattened the vein and it broke out.

Which way of living has the right to life, but especially me wines are more appropriate.

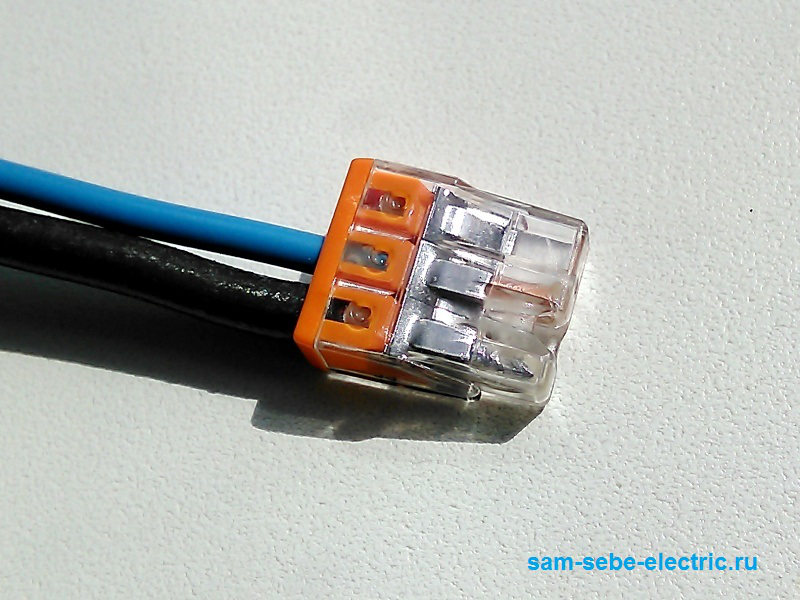

3. For the help of modern universal terminals.

Ce popular and cry out for the greatness of the number of superechok Wago terminals. Special series are produced from Alu-plus contact paste. This paste prevents the appearance of electrical corrosion in the area of contact between aluminum and copper darts. It is possible to change the number of adhesives according to the indications on the "Al Cu" packaging. These are the upcoming Wago series:

- 2273-242, 2273-243, 2273-244, 2273-245, 2273-248;

- 773-302, 773, 304, 773-306, 773-308;

- 273-503;

- 224-111, 224-122.

Znimaєmo іzolyatsiyu s lived on dozhina, vkazan on the terminal block itself.

We insert the leather wire until it stops at the nest (open). Through the opening of the building, one can see that until the end, she lived in the clema.

Such a Wago series is considered to be disposable. They put darts in and then we don’t need it, it’s just breathtaking. If you want to neatly wrap around the sides of your life, then you can pull them up. The axis is only part of the special oil tezh vіdіyde. In the photo below, you can see the oil on the wires and you can see the opening at two openings of the terminal block itself.

4. For help twisting through a ball of neutral speech.

Here there is a strong twisting of two wires. Only the middle vein should be covered with lead-tin solder. So turn on the direct contact of the aluminum with the middle. Twisting must be done carefully, as the aluminum wire can be twisted with slight twisting. Dane z'єdnannya next good isolyuvati. A viable option would be the twisting of a thermo-twisted tube. Especially this option is not suitable, and I did not become a photo of this process. Wanting to htos tsim in the same way coristuetsya.

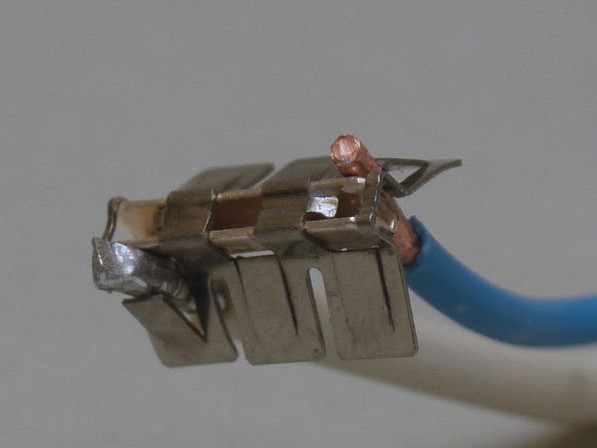

5. For an additional grip of the "Gorikh" type.

About this type of convoy, I reportedly wrote in the article: There you can find out what sorts of terminals there are, how to choose them correctly and how to use them. I won’t repeat it here, but I’ll just post a small photo instruction.

Razbiraemo "gorіh" and cleaned lived on dozhina dies.

We insert the darts at the die from the different sides under the special grooves. Mіzh middyu and aluminum obov'yazkovo may be present protіzhna plate. It includes direct contact between the two metals. Let's tighten up the chatter.

Z'ednannya is inserted into the dielectric housing.

We close the body and put on the place of the stop ring.

I did my best to explain how to zadnuvati midi and aluminum darts my simple. Have I got it? :-)

And in what way do you get copper and aluminum darts together?

Don't forget to laugh:

Judge electrician:

- Why didn't you rush to viconrobe, if Yogo was strumming?

- So, I didn’t think that yoga would be a strum. Screaming like a fiddle.

Most New Buds electrical distribution back to back medium darts. This is dictated by the growth of interest in the mesh, calling the great number of electrical appliances. Krym tsgogo, mіd dovgovіchnіsha, do not oxidize and may have better indications of electrical conductivity.

Ale at the old booths everywhere laid aluminum conduction. A lot of people planning overhaul, change aluminum darts to mid Prote, not everyone can have such a possibility. In addition, sometimes replacement is impossible due to technical reasons.

What next to know

In these vipadkahs, it is necessary to have aluminium, and they lived in midi among themselves. And yet, we’ll forgive the twisting of the fence: between wires, electrochemical corrosion is repaired, viklikana natural moisture, such contact is quickly destroyed. It's best to shoot darts from one material.

Ale z'ednannya midnyh and alyuminієvih provіdnikіv dosit more widely. For whom you can vikoristati different ways, yakі good for themselves have proven practical. The most significant options for such a meeting are presented below.

Methods for reliable connection of various wires

Z'ednati aluminum and copper in electrical wiring can be done in many ways. The main task of all these methods is to ensure reliability and durability of contact, minimizing the possibility of electrochemical corrosion.

Gvintove z'ednannya

The screwed method of connecting aluminum and copper wires is breathtaking in simplicity, being reliable and durable. This variant can be victorious at times, as it is necessary to bring the darts of a different number of the great cross. The essence of that technology, which method is used in the offensive:

- The ends of both wires are cleaned in the form of insulation (approximately 30 mm);

- For help, round-nose pliers are buried in a colo.

Let's take a bolt of the same diameter. Folding structures are carried out in the following order:

- A special washer is attached to the bolt;

- Circumference of the first explorer;

- I know the puck;

- Ring of another dart;

- One more puck;

- The design is squeezed behind an additional nut;

One of the advantages of this method is the possibility of using more than two wires. The maximum number of veins, which are squeezed, are surrounded only by the bolt's dove.

While doing this, do not forget to place washers between the wires: it is impossible to allow copper to come into contact with aluminum conductors.

Dart twist

This way is also widely practiced, but with a special approach. So that the twisting of the mid-sections and aluminum veins was long-lasting, and corrosion did not settle between them, rather, fix it like this:

- They lived in isolation (no less than 4 div);

- Mіdniy drіt needs to be tinned for the help of tin solder;

- After that, a zvichayne twisting of the strum-leading veins is carried out among themselves;

- To increase the protection of such protection against water, it is possible to coat it with a special heat-resistant varnish;

- After hanging varnish, twisting, it is super insulated and ready for use.

The twisting is guilty to be carried out in such a rank, so that they lived twisted among themselves. Wrapping one dart around another is unacceptable!

Terminal blocks

The use of twine blocks is even more popular and widely used in practice. This method is best proven in electrical panels, de є need to build a large number of darts. So the pads get stuck in pink boxes, for the safety of arranging contacts, which will facilitate the revision and repair at the time of consumption.

Let's look at the order of work when choosing a method to combine copper and aluminum:

- Yak zavzhdi, kіntsі drotіv need to be cleaned. Insulation increases by approximately 0.5-1 cm;

- After the cleansing of the ends, they are inserted into the cleats and squeezed with twines from the middle susilla, so that they did not live.

Please! Before that, how to squeeze the single-stranded darts with screws, rather flatten the trochs with a hammer or with pliers. This is necessary for increasing the area of contact.

This method is used both for pads made of black plastic, and for terminals, with more thin insulation made of white plastic. On food, like a block is more beautiful, it’s a thought that there were less terminal blocks (for a mechanical vikonan). Therefore, the stench is most often victorious as an adapter for connecting lamps, chandeliers and other low-pressure lamps.

Okremo it is significant that it is less possible to attach glue under plaster in that case, as if the stench was placed in a box under the roof.

Plugs and terminals WAGO

The most modern version of the shoe for fitting the German WAGO molder. Such adhesives are issued in two types:

- Neroz'єmnі pads mayut lithium often prozory case. For fixation, it was sufficient to insert cleaned ends of the wires into such a cap, zatyskach overly fixing them. The minus of this and that is disposability: in order to rebuild the day, it is necessary to taste the old zatyskachi;

- Roz'emnі klemniki pozbavlenі tsgogo nedolіku. The special importance allows you to easily fix the darts, and if necessary, pick up the air, it’s enough to lift it up the hill, zatyskach rose up and out of the way with glue.

For the help of such zatiskachiv, it is possible to tie a wire harness (type 2 to 8) of the wire, as well as to wire a terminal box as an adapter for wiring in electrical wiring. Another advantage of this method of connecting copper and aluminum is the necessity of additional insulation of contacts. The body of the WAGO pads is completely insulated and superimposed.

Neroz'єmnі z'єdnannya

Let's look at one more way, how to connect copper with aluminum wires. For whom you need a special riveting tool. At times, such outbuildings are widely popular, and already among wealthy masters.

The technology of this method is similar to the method of fixing a bolt and nut. Let's look, like a vicorous riveting tool, you can vikonate on the electric darts:

- Having cleaned them, they lived in isolation, and round-nose pliers turn in a small ring. Importantly, so that the diameter of the buv is yaknameless, so that the rivet does not turn too much;

- Then the structure is folded in the same order as with the screw method: copper and aluminum conductors are put on the hairpin, like a gasket, the washer is small;

- If I cut the rivet into the head, I will add it, the handles of which are squeezed to the clatter. Z'ednannya ready!

The minus of this is the impossibility of arranging the design. If it is necessary to put one more time, the rivet will have to be checked and re-sealed. Also, do not forget about the importance of the isolation of the line of the business: you can win the cambric or the insulating line.

Pіdbivaєmo pіdbags

We lived the widest and most stagnant different materials: midi and aluminum. The stinks are breathable, ensure long-term contact and turn off oxidation, which can lead to electrochemical corrosion.

Many of us know that it is not possible to smash copper and aluminum darts without interruption. Іsnuє kіlka vіdpovіdey on the food chain.

Myth number 1. Aluminum and midi have a different coefficient of thermal expansion. If a strum passes through them, the stench expands in a different way, if a strum sticks, the stench reaches in a different way. As a result, a series of extension-sound changes the geometry of the conductors, and the contact becomes weak. And farther in the place of the filthy contact, the heat is being blamed, the wines are getting hotter even more, an electric arc is appearing, and I will complete everything.

Such a thought is impossible through those that have a linear coefficient of thermal expansion for metals that can be used for electrical installation: mid - 16.6 * 10-6 m / (m * gr. Celsius); aluminum - 22.2 * 10-6m / (m * gr. Celsius); steel - 10.8 * 10-6m / (m * gr. Celsius). However, the inflexibility in the linear thermal expansion is easily compensated for by the overpressure of the overpressure, which creates a permanent pressure on the contact. Let's expand the metal, we'll squeeze the well-tightened bolted connection for help, we'll only get killed, and the temperature drops can't seriously loosen the contact.

Myth number 2.Aluminum makes an impervious oxide coating on its surface, as from the very cob the contact deteriorates, and the process is followed by a growing one: heating, further deterioration of the contact, arc and ruinuvannya. This option is also not known, because oxide smelting allows the use of aluminum conductors instead of steel and other aluminum conductors.

Myth number 3.Aluminum and copper make a “galvanic couple”, as it is simply impossible not to overheat at the contact point. I reheat, arc and so on. prote, medniy drіt nick tezh dosit quickly pokryvaetsya okis s tієyu raznityu, scho okis midi big-mensh to carry out strum. As a matter of fact, copper and aluminum conductors, their oxides can decompose on charge of ion. They aluminum oxide and midi, being particles with a different electrical potential, begin to take part in the process of stream flow. The process is being started, like "electrolysis". In the course of electricity, they carry charges and move themselves. When they move, the metal collapses, the empty shells settle. Aluminum is especially valuable. Well, and there are empty shells, there is no longer possible to have a natural electrical contact. The filthy contact begins to grow, it becomes more and more severe, and so on until the loan.

Particularly unsafe is the construction of a copper and aluminum dart on the street. Under the influx of natural moisture and passage through the pipeline electric struma the process of electrolysis and the outdoors, the process of destroying the contact will be significantly accelerated. As a result, in the area of \u200b\u200bz'єdnannya, shells are settled, heating and sincere contacts are being heated, and insulation is being charred.

How to properly connect copper and aluminum conductors.What is the work, if it's necessary to use the resources? There are only two paths left: back through the other metal or use the sealed rubble oxide smelting. The first type of vikoristovuyutsya different z'ednuvachi: terminal pads without a direct dotik of various conductors, a zahisny ball from the third metal, washers, special tips.

Special pastes are used to seal midi and aluminum with vicor, to protect the contact from the oxidation of the water, to pass the far contact to the contact. If a third is needed for the friendship of these two metals, then you can make one of them. For example, puddles of medny baggage allowance miraculously vikonaє zavdannya at the connection with single-stranded aluminium.

For a specific plant, connection to an aluminum riser in the underside of the shield is made of vicorous clasps (grips) with or without punctures. The stench is an intermediate plate that turns off the middle contact. Є copies like with paste, so without it. For larger butteries, it is possible to vicorate terminal blocks with partitions or other sockets for conductors made of midi and aluminum. It is possible to make a victorious bolt z'ednannya, but do not forget to lay a washer between the middle and aluminum rods, galvanized or stainless steel.

About those in electrical wiring it is not possible to insert copper and aluminum darts, to know how to build a rich habitation, without seeming already about professional electricians. In this article, we will try to find answers to the question: "Why can't you work?" It would have been better, for the old norms and the rules electrical wiring zastosovuvalis like copper, and aluminum darts. The stench could have been freely connected in one wire! They could (okremі linії), ale zadnuvati could not! If the stench started to rise, then it was necessary to constantly control the month of the day. Otherwise - heating up and burning up!

From which drive is blamed the natural power: “ And why do you feel sleepy? Why should the middle of the steel not burn, the aluminum of the steel should not burn, and the aluminum of the middle - to burn?!

On the rest of the supply, you can feel the difference. Axis part of them:

Aluminum and midi have a different coefficient of thermal expansion. If a strum passes through them, the stench expands in a different way, if a strum sticks, the stench reaches in a different way. As a result, a series of extension-sound changes the geometry of the conductors, and the contact becomes weak. And farther in the place of the filthy contact, the heat is being blamed, the wines are getting hotter even more, an electric arc is appearing, and I will complete everything.

Aluminum makes an impervious oxide coating on its surface, as from the very cob the contact deteriorates, and the process is followed by a growing one: heating, further deterioration of the contact, arc and ruinuvannya.

Aluminum and copper make a “galvanic couple”, as it is simply impossible not to overheat at the contact point. I reheat, arc and so on.

Is it true and what is true in the areas of production of midi and aluminum?

First of all, it is impromptu to guide you. The axis of the tabular data for the linear coefficient of thermal expansion for metals, which is required for electrical installation: mid - 16.6 * 10-6 m / (m * gr. Celsius); aluminum - 22.2 * 10-6m / (m * gr. Celsius); steel - 10.8 * 10-6m / (m * gr. Celsius).

It is obvious that the yakbi on the right was in the expansion coefficients, then the least important contact buv b between steel and aluminum conductor, even if their expansion coefficients are doubled.

But without tabular data, it is clear that the performance in the linear thermal expansion is easily compensated for by the overpressure of the overpressures, which creates a constant pressure on the contact. Expansion to metals, we squeeze, for example, for the help of a well-tightened bolted connection, only a little more is left, and temperature drops are not enough to seriously loosen the contact.

The option of oxide melting is also not known. Even though oxide smelting itself allows the use of aluminum conductors with steel and with other aluminum conductors. So, obviously, it is recommended to apply a special oil against oxides, so, a systematic revision is recommended with regard to the participation of aluminum. Ale, everything is allowed and practiced by fate.

And the axis version with a galvanic couple is right for the base. Ale here still can not do without oxides. Aje middle conductor tezh dosit shvidko pokrivaєtsya oxide s tієyu raznityu, scho midi oxide more-less to carry out strum.

Ale, as well as the copper and aluminum conductor, their oxides may be able to dissociate, so that they will decay on the charge of the ions. Dissociation is possible for natural hair, for example, in the air. They are oxides of aluminum and midi, being particles with a different electrical potential, begin to take part in the process of stream flow. The process is being started, like "electrolysis".

In the course of electricity, they carry charges and move themselves. Ale, moreover, they are parts of metal conductors. When they move, the metal collapses, the empty shells settle. Aluminum is especially valuable. Well, and there are empty shells, there is no longer possible to have a natural electrical contact. The filthy contact begins to grow, it becomes more and more severe, and so on until the loan.

It is significant that there is more moisture dovkilla, moreover, the transfer processes are intensively proceeding. A non-thermal thermal expansion and a sphere of aluminum oxide, which should not be carried out, is only a tightening factor, no more.

It is not uncommon to wind up at the time of stretching new wiring to be connected with copper wires with aluminium. That would be used on the introduction to the booths, even the wire of the LEP for aluminum, and also, to come to the next line of the same aluminum wire, or the medium, but with the guards. It is not possible to bring two numbers of metal together without a middle, and the axis of what is needed. Copper and aluminum are metals of different activity, they have different opirnist, different and other physical powers. On copper, the current collapses with the smallest support, which means that the building capacity of the middle darts is high. Not only that, but the direct twisting of copper and aluminum wires causes problems.

What does it look like with direct twisting

For the cob we will sort it out with a throughput capacity. Show that you are letting water through pipes of a sufficient diameter. Let's step by step increase the pressure on the water. Sooner, the moment will come, if I don’t blow the trumpet through the building, the vice has more growth, and it will be better. Mayzhe tse vіdbuvaєtsya i drotі. The movement of the opir in aluminum should be warmed up, as if it would be twisted with the middle wire of the same section. Ale, the most headless one, gets herself twisted at the mist.

Chemical properties of metals

Entering into a reaction with sour water, metal, as it seems, begins to oxidize. The degree of oxidation and the power of oxide smelting are different in them. At the midpoint, the process proceeds properly, and oxide smelting can lead to the conductivity of the stream. And the axis on aluminum oxide smelting is different, and it’s even worse to carry out a strum. As a result, a zone of a moving or active transitional support is created on the twist, which may be like a spiral of your home electric kettle or prasky. Stronger heating is expected. But still not all.

Acts of physical power of metals

We also know well about the linear expansion of metals. Mid and aluminum have a different stench. They gave the tension - the twisting heated up, the darts expanded unevenly, they took the tension - it became ringing, the twisting weakened. Dzhe shvidko schіlnіst skruchuvannya vtrachaєє - start sparking! This is the most safe moment, if high temperatures and at the same time from the width become the cause of fire.

How to get rid of problems?

A deck of simple rules:

- Reach out to professionals, zamovlyayuchi electrical installation services - stink for sure, everything is broken up correctly, it will be necessary to wind up the copper and aluminum darts.

- Vikoristovyte transitional metals or special z'ednuvachs - a great metal bolt, three washers and a nut - an axis for you and a primitive way of connecting through metal. Ale on the market of electric control of the mass of the rіznih z'єdnuvachіv on the terminals, yakі specially for this purpose, є і transitional plates.

- Ludinnya - just a soldering iron and soldering iron under the hand - go ahead, tinker with a mid-drill (you don’t see it with an aluminum wire, you won’t need it anyway)

- Zmaschennya - additionally zastosovyte special oil, so as not to allow the metals to oxidize

- Properly account for the vanity - have a kind of vipadku lived aluminum drotu maє buti a bigger cut lower mid. Otherwise, the aluminum plate will be heated

You can get all the special supplies and oils in the electrical supply stores, but the stink of the fahivtsy is still there. І the last joy - not varto zaoschadzhuvati. Let everything be done more quickly from the middle wires, if you want it to be more expensive. Then zrobite once and forget about the problems. There are more companies that provide services to electrical installation, sell materials at the most reasonable prices, which you can’t buy at stores.