Connection of a three-phase electric motor. What are the main parts of the machine. Exhalation of the struma under the hour of passage through the chamber

Asynchronous electric motors are widely zastosovuyutsya in the industry of soundness and simplicity of design, good working characteristics, manual control.

Similar attachments are often used to the hands of a home master and wine, corroborating knowledge of the basics of electrical engineering, connecting such an electric motor for robots in a single-phase line of 220 volts. Most often it is victorious for emery, trimming wood, trimming grains and other simple work.

Navіt on okremih promyslovyh verstatah and mehanіzmа іz drives zastrіchayutsya zrazy raznyh dvigunіv, zdatnyh pratsyuvati vіdnієї ї ї ї ї trokh phases.

The most common stench is victorious capacitor start-up, as the simplest and most acceptable, although the only way, with the help of more competent electricians.

The principle of operation of a three-phase dvigun

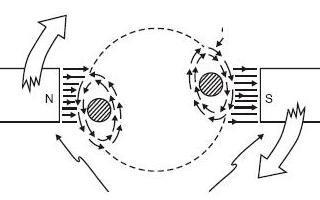

Industrial asynchronous attachments of the 0.4 kV system are produced with three stator windings. Tension is applied to them, they are pushed along the kutu by 120 degrees and call streams of a similar shape.

To start the electric motor, direct the streams in such a way that the stench created a total electromagnetic field, which wraps around, optimally flows onto the rotor.

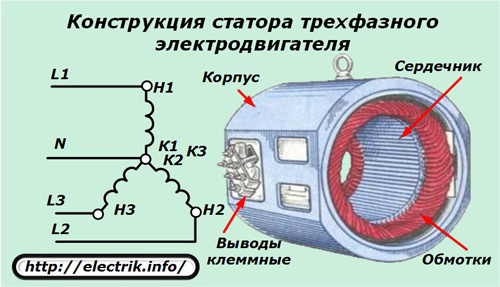

The design of the stator, vikoristovuvan z tsієyu method, is presented:

1. body;

2. magnetic circuit of the core with windings placed in the new triple;

3. with clamps.

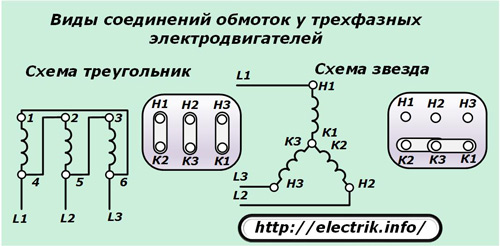

At the splendid vikonanna insulated darts windings are selected for the scheme of the star for the rakhunok, a jumper is installed between the terminal screws. Krіm tsgogo іsnuє podklyuchennya, zvane trikutnik.

In both windings, the windings are recognized directly: the cob and the end, the wrapping from the installation method - the winding during preparation.

Windings are numbered Arabic numerals 1, 2, 3. Їх kіntsi are designated K1, K2, K3, and on the cob H1, H2, H3. In other types of engines, a similar way of marking can be changed, for example, C1, C2, C3 and C4, C5, C6, or other characters, or else do not zastosovuvatsya.

Properly applied marking makes it easier to connect live wires. When the windings of the symmetrical scheme of the voltage expansion are arranged, the nominal streams are aligned, which ensures the optimal operation of the electric motor. In this way, their shape in the windings is constantly changing the voltage, which is to be introduced, I repeat it without any doubts.

Obviously, following the understanding, that this is a theoretical statement, but in practice, the streams add different supports, the trochs are breathed.

On-the-fly spriynyattyu processes, scho vіdbuvayutsya, help the image of vector quantities on the complex plane. For a three-phase motor, the streams in the windings, which are applied with a symmetrical voltage, are displayed in this way.

When an electric motor is powered by a system of voltages, with three equally spaced along the coil and vectors of the same magnitude in the windings, the same symmetrical jets flow.

Skin їх utvoryuє elektromagnіtne field, the force of іnduction ії kogo induce in the windings of the rotor in the field of the magnetic field. As a result of the collapsible interplay of the three fields of the stator with the field of the rotor, the wrapping of the rest is created, ensuring the creation of the maximum mechanical tension that wraps the rotor.

Principles of connecting a single-phase voltage to a three-phase motor

For a full connection of up to three identical stator windings spaced 120 degrees apart, two voltage vectors per day, and only one of them.

You can put yoga in one winding and shake the rotor around. But it is efficient to vikoristovuvat such a dvigun not viide. Vіn matima, there was even a little tightness on the shaft.

This is the fault of the manager of the connection of the phase circuit in such a rank that she did it in different windings symmetrical system strumiv. In other words, it is necessary to change the voltage of a single-phase line to a three-phase one. Similar assignments are violated by different methods.

In order to create folding schemes of current inverter installations, it is possible to implement such extended methods:

1. vikoristannya condenser start;

2. installation of throttles, inductive supports;

3. folding of different direct streams in the windings;

4. combinations of methods with phase support shifts to establish the same amplitudes in the streams.

Let us briefly examine the principles.

Exhalation of the struma under the hour of passage through the chamber

The most widely practiced is a capacitor start, which allows a strum to be blown into one of the windings for the connection of the sump support, if the strum is projected in the direction of the applied voltage vector by 90 degrees.

As capacitors sound like vicorous metal constructions of the MBGO, MBGP, KBG and similar series. Electrolytes are not connected for passing snake struma, Shvidko vibrates, and the schemes, which convey their victories, exude foldedness, low arrogance.

In this scheme, the strum is ventilated as a nominal value. The wind is less than 90 degrees, not reaching 30 pro (120-90=30).

Breathing the struma for an hour of passage through the inductance

The situation is similar to the previous one. Only here the strum shows the voltage at your own 90 degrees, but not thirty. In addition, the design of the inductor is not as simple as that of a capacitor. You need to expand, choose, set up for an individual mind. Tsey way without nabuv wide width.

When vikoristanny condensers and abo drosels in the streams in the windings of the electric motor do not encroach on the necessary cut on the thirty-degree sector, the indications in red colors in the picture, which already creates an increase in the consumption of energy. Alya has to be reconciled with them.

The stench is responsible for the creation of an even distribution of forces of induction, creating an effect that is galm. Dostovіrno otsіniti yogo vpliv smoothly, but with a simple approach, rozpodіlu kutіv go out (30/120=1/4) the cost is 25%. However, why can you rahuvati like that?

Exhalation of the struma by applying a voltage of reverse polarity

In the scheme of the star, a phase wire of the voltage is connected to the input of the winding, and a zero one - її kinets.

If in two separations by 120 pro phases apply one and the same voltage, but divide them, and in the other change the polarity, then the streams will destroy one by one along the kutu. The stench forms the electromagnetic field of the razor straight ahead, which adds to the vibrating tension.

Only with this method, the air strums come out on the kut at a small value - 30 o.

Tsim method koristuyutsya okremih vipadkah.

Methods complex zastosuvannya capacitors, inductances, change of polarity of windings

The first three methods are not allowed to create one by one optimally symmetrical windings in the windings. Vyvzhd vinikaє їх peroxide according to the cutout of a stationary scheme, transferred for a triphasic full-time living. For the account of which, there are opposing moments, which make the winding up, which lower the KKD.

To this end, the researchers conducted numerical experiments, which are based on various methods of their transformation, which ensure the greatest efficiency of the robotic three-phase engine. Circuit diagrams with a detailed analysis of electrical processes can be found in special textbooks. Їx education promotes the rіven of theoretical knowledge, but the stench of the world is rarely practicable.

A good picture of the spread of the stream is created by the scheme, if:

1. one winding is supplied with a direct-on-line phase;

2. on the other, that third of the winding is connected to the voltage through the capacitor and the choke is viable;

3. In the middle of the conversion scheme, it is necessary to change the amplitudes of the streams for the selection rate reactive supportsіz compensation unbalance by active resistors.

I would like to give respect to the third point, for which a lot of electricians do not give importance. Just marvel at the next picture and learn about the possibility of a uniform rotor wrap with a symmetrical addition to new forces, the same and different in magnitude.

The complex method allows you to create a folding scheme. Vaughn rarely zastosovuєtsya practical. One of the options for implementation for an electric motor with a pressure of 1 kW is lower.

For the preparation of a transformation, it is necessary to create an uneasy throttle. Tse will require spending time and material resources.

It’s also a problem to blame when looking for resistor R1, which will work with strums, which will change 3 amperes. Vin is guilty:

vodity to sweat, which exceeds 700 vats;

chill well;

superficially isolated from strum-conducting elements.

It is necessary to use more technical folds, so that you can do it to create such a change of three-phase voltage. However, the screw is universal, allowing the connection of a motor with an intensity of up to 2.5 kilowatts, ensuring its operation.

Also, the technical power supply of a three-phase asynchronous motor single-phase mesh virisheno at looking at the folding scheme of the reworking. Ale vin do not know practical zastosuvannya for one simple reason, which is impossible to get through - the dependence on the supply of electricity by the reworker himself.

The tension that is seen through the creation of the scheme three-phase voltage similar design, which exceeds the minimum of the second time and consume the electric motor itself. With all the sumarnі vantazhennya, svoryuvanі on the electrical wiring, scho to bring life, you can compare with the work of the old zavaryuvalnyh devices.

The electric lichinik, to the delight of the sellers of electricity, soon begins to reinvest pennies from the gamantsy of the home master on the account of the energy-supplying organization, but it doesn’t suit the rulers. As a result, the folded technical solution of the creation of a good voltage switch turned out to be indispensable for practical stosuvannya in the home state, and industrial undertakings tezh.

4 wrappings

1. It is technically possible to switch a single-phase connection of a three-phase motor. For whom a lot of different schemes have been created from a different elemental base.

2. Practically zastosovuvat tsey method for trival work and drives in industrial verstats and mechanisms underestimated through great expenses energy saving, created by third-party processes, which lead to a low CCD of the system, the promotion of material costs.

3. At home minds, the scheme can be reversed for short-time robots on non-standard mechanisms. For a long time, such attachments can be used, but if so, the payment for electricity is significantly increased, and the pressure of the working drive is not guaranteed.

4. For the efficient operation of an asynchronous motor, it is better to turn on the three-phase mesh eating. If there is no such feasibility, then it is more likely to be in the form of a winding and a sudden tightness.

From the widest range of electric motors, which are launched at the present time, the widest range of motors is asynchronous three-phase. Mayzhe half of the electricity generated by the world is driven by the machines themselves. The stench is widely zastosovuyutsya in metalworking that woodworking industry. Asynchronous motor is indispensable in factories and pumping stations. You can't do without such machines in the butt, the stench vikoristovuyutsya and in other home technіtsі, and in power tools.

Cich stagnation area electrical machines expand with the skin day, so that both the models themselves and the materials for their preparation are perfected.

What are the main parts of the machine

By solving a three-phase asynchronous motor, you can design two head elements.

1. Stator.

One of the most important details - stator.In the photo of the animal, a part of the dvigun is zapped. Vin is composed of the following main elements:

1. Frame. Vіn is necessary for the storage of all parts of the machine. As the engine is small, the body is made of a solid cast. As a material vikoristovuyut chavun. Zastosovuyutsya also steel or metal aluminum. One case of small motors for the same function of the core. If the engine can be large and tight, then the hull is built from four parts.

2. Core. The main element of the engine is pressed into the body. To serve as a wine for the expansion of the magnetic induction cells. The core is made from electric steel plates. To reduce the cost, inevitably, due to the appearance of vortex streaks, the skin plate is covered with a ball of special varnish.

3. Winding. It is located at the grooves of the core. Stacked from coils honey dart, which are taken from the section. Z'ednani in song sequence, the stench is made up of three coils, like a stator winding. It connects directly to the middle, to which it is called the first.

Rotor- The part of the engine is broken. The photo of the vin is right-handed. Serve as a wine for transforming the strength of magnetic fields on mechanical energy. The rotor of an asynchronous motor is assembled from the following parts:

1. Shaft. Bearings are fixed on the shanks of yoga. The stench is pressed into the shield, which is bolted to the end walls of the stator box.

2. Core that climbs on the shaft. It is made up of plates of special steel, which can have such a price of power, like a low support for magnetic fields. The core, with the shape of a cylinder, is the basis for laying the armature winding. Rotorna, otherwise, as they call it, the secondary winding takes energy away from the magnetic field, as if the stator coil appeared right next to the stator coil for an hour when they passed the electric stream.

Move according to the type of preparation of the dry part

Separate engines:

1. Wash the short-circuited rotor winding. One of the options for viewing the details of indications for a baby. ![]()

An asynchronous motor with a short-circuited rotor has a winding, zroblenu with aluminum strands, which are milled in the grooves of the core. At the end part, the stench is short-circuited with rings.

2. Electric motors to make the rotor, made from contact rings.

In both types of asynchronous motors, the stator design is the same. The stench breaks out less than the anchors.

What is the principle of robotics

The yakir of a three-phase asynchronous dvigun, chiming in a similar rank, wraps around the effect of the vindication of the chang- ing magnetic field in the stator coils. In order to understand how you see it, it is necessary to guess the physical law of self-induction. We can say that it is like a conductor, like passing through the flow of charged particles, the magnetic field appears. The value of yoga will be directly proportional to the inductance of the core and the intensity of the flow of charged particles that flow into the sky. In addition, the magnetic field forms a force with singing straightness. Itself won't cackle us, shards are the cause of wrapping the rotor. For efficient work dviguna need a hard magnetic potik. Created in the windings by a special method of installation of the primary winding.

We see that life is waiting for you changing voltage. Also, the magnetic field near the stator is the same characteristic that it is possible to lie without a middle in the form of a struma in the measure that it gives. It is noteworthy that the skin phase is shifted one visually further by 120˚.

What is in the stator winding

The skin phase of the lifeline is connected to the stator coil, so the magnetic field that causes them will be shifted by 120˚. Dzherelo zhivlennya can change the voltage, then, like the stator coil, like an asynchronous motor, we can change the magnetic field. The scheme of an asynchronous motor is selected so that the magnetic field, which is caused by the stator coils, changes step by step and sequentially passes from one winding to the other. In this way, the effect of the magnetic field is created, which turns around. You can assign this wrapping frequency. Win in turnovers for whilina. Depends on the formula: n=60f/p, where f is the frequency of the changeable struma in the connected circuit (Hz), p is the number of pairs of poles mounted on the stator.

How to work the rotor

Now it is necessary to take a look, how processes are blamed on secondary winding. An asynchronous motor with a short-circuited rotor may have special design features. On the right, in that no voltage is applied to the yakir winding. It is there that the windings of the magnetic induction connection with the primary winding are blamed. To that, there is a process that turns out to be in the stator, according to the law, which is to say that when the conductor breaks, and in our case the rotor winding is short-circuited, the magnetic flux in the new blame electric strum. Are the stars taken from the magnetic field? Vono viniklo like the primary cat when connected to a three-phase dzherel zhivlennya.

Z'єdnaєmo stator and rotor. What can you see?

In this way, there can be an asynchronous short-circuited motor with a rotor, in which winding an electric stream passes. Vin and will be the cause of the fault of the magnetic field around the anchor winding. However, the polarity of the current flow is affected by the created stator. Obviously, and the power created by him, we enter into protidium with tієyu, which is viklikana by the magnetic field of the primary winding. That’s why I brought the rotor into rotation, so that the secondary coil was selected on the new one, the shanks of the armature shaft are fixed in the engine housing on bearings.

Let's take a look at the situation of the interplay of forces that are blamed on the magnetic fields of the stator and the rotor, for an hour. We know that the magnetic field of the primary winding wraps around and changes the frequency. Created by him is the power to move, looming similar to swidkist. Tse zmusit asynchronous dvigun zarobiti. І th rotor is free to wrap around the axis.

Forging effect

The situation, if the power flows of the rotor seem to be blowing out of the magnetic field of the stator, which turns around, took away the name of the forge. Next, set the frequency of the asynchronous motor (n1) to be less than the one that moves the stator magnetic field. You can explain it this way. Shchob at the rotary winding screw strum, it is guilty of buti twisted by a magnetic flux with a song kutovy shvidkistyu. To this, it is fair to say that the speed of the wrapping of the shaft is greater than zero, and even less the intensity of the displacement of the stator magnetic field. The rotor has a frequency of wrapping, which is due to the force of friction in the bearings, as well as to the magnitude of the amount of tension in the rotor shaft. That's why you see the magnetic field of the stator. Through itself, the frequency is called asynchronous.

In this manner, the electricity of the living quarters turned into kinetic energy the shaft that wraps around. The speed of this wrapping is directly proportional to the frequency of the life stream and the number of pairs of stator poles. To increase the frequency of the wrapping of the anchor, you can twist the frequency shifters. However, the work of these outbuildings may be supported by a large number of pairs of poles.

How to connect the engine to the dzherel life

To enable the start of an asynchronous motor, it is necessary to connect it to the triphasic struma. The asynchronous motor circuit is selected in two ways. The small diagram shows the wiring diagram of the motor, into the stator windings by the “zirka” method.

On this little image there is another way to get it, which I can call "trikutnik". Schemes are selected in a terminal box, which is fixed on the body.

The last thing to know is that the cob of leather from three coils, which are also called phase windings, are called C1, C2, C3, obviously. Similarly, the letters are signed, as they may be called C4, C5, C6. Even though there is no marking of visnovkiv in the terminal box, then the cob of that kіnci happens to be marked independently.

Yak zrobiti reverse

In case of faulty consumption, it is necessary to start the asynchronous motor by changing the armature wrapping directly, you just need to remember the two rods of the three-phase voltage that are connected.

Single phase asynchronous motor

It is problematic to switch three-phase motors through the presence of a necessary voltage supply. To that є single-phase asynchronous dvigun. Vіn also maє stator, but from the suttєvoyu constructive vіdmіnіstyu. Vono is used in the quantity and methods of winding roztashuvannya. Decide how to start the machine.

If a single-phase asynchronous motor has a stator with two windings, then the stench will be spread around the coil at 90˚. Cotushki are called launchers and robots. The stench is coming up in parallel, but, to create a mind for the appearance of a magnetic field, what to wrap around, to introduce additionally active opir chi capacitor. The windings windings winding phases, close to 90˚, are created, which causes the mind to create a magnetic field that wraps around.

If the stator has only one coil, then connecting to it with a single-phase life will be the cause of a pulsating magnetic field. At the short-circuited windings of the rotor, an alternating strum will appear. You can blame your magnetic flux. As a result of the two forces that have settled down, the result is zero. To start the engine, if you have such a design, you need additional supplies. You can do it by connecting the start capacitor circuit.

Connect the motor to a single-phase lance

![]()

Preparations for work in the case of a three-phase dzherel zhilennya, the electric motor can be used in the case of a home single-phase merezhi, but if this is the case, its characteristics will decrease, such as the KKD coefficient of tension. In addition, tension and start-up displays will decrease.

Well, you can’t do without a connection, you need three stator windings to choose a circuit, there will only be two. One robot, and another launcher. For example, there are three kotushki with cobs C1, C2, C3 and the ends C4, C5, C6 are clear. For the folding of the first (robot) winding of the motor, it is connected to the ends of C5 and C6, and the cob of C3 and C2 is connected to the dzherel single-phase strumu for example, 220 volts by butovy. The role of the other, starting winding, will be played by the non-separated starter coil. It is connected to the dzherel of life through a capacitor, connected from it in sequence.

Parameters of asynchronous motor

When choosing such machines, as well as during further operation, it is necessary to check the characteristics of the asynchronous motor. The stench is energizing - the coefficient of brown energy, the coefficient of tightness. It is important to call me at mechanical displays. The main of them is the staleness between the shvidkistyu wrapping the shaft and the working susillas that are applied to the new one. Use more start-up parameters. The stench determines the starting, minimum and maximum moments and їх spіvvіdnoshenya. It is also important to know, which is the starting strum of an asynchronous engine. For the most effective victorious engine, it is necessary to check these parameters.

It is impossible to deprive the posture of respect for energy conservation. In the rest of the hour, wines are looked at not only from the position of the change in operational costs. The economy of electric motors is reduced environmental problems, related to the generation of electricity.

Before the harvesters, the task of rozrobka and the release of energy-saving engines, increasing the operational resource, changing the noise level, is constantly put in front of the workers.

Polypshiti energy-saving indicators can be a way to reduce costs for an hour of operation. And the stinks lie in the working temperature of the machine. In addition, the perfection of these characteristics will inevitably lead to an increase in the term of operation of the engine.

It is possible to reduce the temperature of the windings by stopping the fan of the wind blowing, fastening to the shank of the rotor shaft. Ale tse to bring up to the inevitable increase in noise that vibrates with the engine for an hour of work. Particularly noteworthy is the showcase for the high speed of the rotor wrap.

In this rank, it is clear that an asynchronous dvigun can only be short. Vіn not building to increase the constant frequency of wrapping the shaft with growing voltages. Prote such a dvigun can be impersonal in comparison with similar electric motors of other designs.

First of all, I can't imagine the design. The robot of the asynchronous motor does not call the daily folds when it is changed.

In another way, an asynchronous motor is economical in terms of performance and operation.

Thirdly, this machine is universal. Possibility of vikoristannya in any kind of outbuildings, yakі vimagayut exact frequency control wrapped around the armature shaft.

Fourthly, a motor with an asynchronous principle of requesting and in operation, otrimuyuchi life is more than one phase.

Connection

Skin asynchronous three-phase dvigun for two rated voltage three-phase lines 380/220 - 220/127 and so on. The most common motors are 380/220V. Switching the dvigun with the same voltage on the other way is carried out by connecting the windings “to the star” - for 380 V or to the “trikutnik” - to 220 V. If the dvigun may have a connection block, then there may be 6 connections with the installed jumpers, the next jumpers should be put in order in order . If the dvigun has a daily block and є 6 vysnovkіv - ring the stench of the pick in bunches of 3 vyvedennya. In one bundle, the cob of windings is selected, in the other end (the cobs of windings are marked with a dot on the diagram).

At times “cob” and “kіnets” - understand the mind, it’s important that the windings were not directly wound, i.e. from the butt of the “zirka” the zero point can be like a cob, and the ends of the windings, and the “trikutnik” - the windings are due to buti z ' One day in a row, then the end of one with the cob of the offensive. For the correct connection to the “trikutnik”, it is necessary to designate the leather windings, arrange them in pairs and connect the following. scheme:

![]()

As soon as you open up this scheme, you will see that the coils are connected with a “tricutnik”.

If the motor has less than 3 windings, the next step is to take the motor apart: remove the cover from the side of the block and in the windings know the number of three winding wires(All other darts are collected by 2). Z'ednannya three darts є zero point of the star. Qi 3 darts should be ripped apart, soldered to them to see the darts and combined into one bundle. In this rank, we may already have 6 wires, as it is necessary to connect to the tricutnik circuit.

The method of designating the beginnings and ends of the windings of a three-phase asynchronous motor

On the back it is necessary to designate the windings. For this, the windings are called with an ohmmeter and they are taken into mental bundles of 3 pieces.

A battery is connected to the windings of one of the windings (for example A1-A2), and a shooting voltmeter is connected to the windings of the other windings (B1, B2) (the digital multimeter is not supposed to be too inert). (div. below diagram)

At the moment I open the contact of the winding A with a battery, the arrow of the voltmeter hits in the yakus l. bik.

The battery is left on the same winding (preserving the polarity), and the voltmeter is connected to the forward winding - Z. Changing the polarity of the winding Z (minifying the windings of the winding by the places of the winding) achieves the release of the voltmeter in the same direction as in the front winding.

In this order (div. Scheme 1), when the contact of the winding A with the battery is opened, the voltmeter, being connected to the winding and connected to the winding C, is guilty of hitting the arrow in one beat. As the arrow goes up at different sides - remember the places (laying at different bunches) of the visnovi B1 and B2 or C1 and C2.

Connect the battery to the connections of the winding C (div. circuit) and reach in the same order, so that when the contact with the battery is opened, the needle of the voltmeter connected to the winding A sips in the same line as the voltmeter is connected to the winding B. Yakshcho the arrow goes in different sides on winding A and winding B, - remember the windings of winding A. (take care of the polarity of the voltmeter and batteries)

Turn over again from the very cob.

Such a rank can be taken.

when opening the contact of the battery with any of the windings on the other two windings, a short-hour electric potential of the same polarity is to blame (then the voltmeter needle is guilty of hitting one beat).

Now vysnovki, which are in one bundle, should be designated as "on the cob", and visnovki, which are in a different bundle - like "kintsi"

Asynchronous motors

Under the heading "Zahalne" we can look at the area of congestion, proportional characteristics, advantages and shortcomings of three-phase and single-phase asynchronous motors. We can also look at the possibility of connecting a three-phase motor to a minimum of 220 volts. Asynchronous motors in our time are widely occupied in various areas of industry the strong state. The stinks vikoristovuyutsya like electric drives in metalorizalnyh verstats, conveyors, pyomno-transport machines, fans, pumping equipment, etc. Engines of low pressure are stuck at the outbuildings of automation. Such a wide application of asynchronous electric motors is explained by their advantages in comparison with other types of motors.

Asynchronous motors, according to the type of voltage, can be single-phase and three-phase. Single-phase, it is important to vicorate up to an intensity of 2.2 kW. Tse obezhennya for potuzhnistyu pov'yazane through a great start-up and working jet. The principle of operation of single-phase asynchronous motors is the same as in three-phase ones. With a single difference, single-phase motors have a lower starting torque.

The principle of robotic circuit for connecting three-phase motors

We know that an electric motor is made up of two main elements of the stator and the rotor. The stator is an unruly part of the engine, and the rotor is a rumpled part. Triphasic asynchronous motors there are three windings, yakі roztashovyvatsya vіdnosno one one pіd kutom 120 °. If a change of voltage is applied to the windings, a magnetic field is created at the stator, which wraps around. It is called a change strum: a strum, which periodically changes its direction electric lansyug From the same time, the average value of the strength of the struma in the period is equal to zero. (Figure 1).

The phase of the baby is depicted as a sinusoid. The magnetic field of the stator, which wraps around, forms a wrapping magnetic pot. Shards of the stator magnetic field, which wraps around, collapses more than the rotor, then it is under the influence of induction jets that settle in the rotor windings, creating a magnetic field of the rotor. The magnetic fields of the stator and rotor form their own magnetic fluxes, these fluxes are attracted one to one and create a moment that wraps, for which the rotor begins to wrap. You can marvel at the report about the principle of operation of three-phase motors.

At the terminal well, three-phase motors can have three to six terminals. Either the ear of the windings (3 clamps) or the ear and the end of the windings (6 clamps) are shown on the circuit of the terminals. The cob of windings is taken to be denoted by the Latin letters U1, V1 and W1, the ends are designated as U2, V2 and W2. In domestic motors, the windings are designated C1, C2, C3 and C4, C5, C6, respectively. In addition, in the terminal box, there can be butts and additional terminals on the yak, a thermal shield can be generated, which will be introduced into the windings. For motors, if you can make six terminals, there are two options for connecting windings to a three-phase line: “star” and “trikutnik” (Mal. 2).

The connection behind the “star” circuit (Y) can be removed, in order to close the terminals W2, U2 and V2, and to the terminals W1, U1 and V1 apply voltage to the lifeline. With such an increase in the strum of phases, the strum of the phases is more dense, and the voltage of the phases is more equal, the stress of the strum is divided into the root of three. and V1 apply the voltage of life. With such an added strum of phases, the strum of the struma is more dense, and the voltage of the phases is more equal, the stress of the strum is divided into root of three. life voltage jumpers. With such an adjoining strum of phases, the struma of the struma is divided into three, and the voltage of the phases is equal to the strain of the strand. For the help of these circuits, you can connect a three-phase asynchronous motor to two voltages. If you look at the nameplate of a three-phase motor, then the operating voltages are indicated there, with some kind of electric motor data (Small. 3).

For example, 220-240/380-415: the motor runs on a voltage of 220 volts when the first windings are connected to the “tricutnik” and 380 volts when the windings are connected to the “star”. More low voltage, the stator windings must always come to the "trikutnik". More high voltage windings are attached to the "star". The strum when the dviguna is connected to the "tricutnik" is 5.9 amperes, when connected to the "strum" the strum is 3.4 amperes. To directly change the wrapping of a three-phase asynchronous motor, remember to remember the times, whether it be two darts on the terminals.

The principle of robotic circuit for connecting single-phase motors

single-phase asynchronous electric motors Mayut two windings, yak_ roztashovanі pіd kutom 90 ° vіdnosno one one. One winding is called the main winding, and the other winding is called the starting or auxiliary winding. The fallow number of poles of the skin winding can be divided into sections. Between single-phase and three-phase dvigunami іsnuyut vіdminnostі. A single-phase motor has a change of poles during a skin cycle, and a three-phase magnetic field has to live. Single phase electric motor it is not possible to start the robot on its own. For yoga run vicariously different ways: start through a capacitor and a robot through a winding, start through a capacitor and a robot through a capacitor, with a constant starting capacity, with a rheostatic start. Single-phase, eclectic motors, equipped with a working capacitor, are permanently connected and connected in series with the starting (additional) winding. In this rank, the starting winding becomes additional, if the electric motor reaches the operating frequency of the wrap. You can look at how the windings are connected in a single-phase motor (Fig. 4)

For single-phase asynchronous motors є deyaki obezhennya. The stench in the same time is not to blame for the work at low pressures and in the idling mode, overheating of the engine occurs. For these reasons, it is not recommended to operate the engine with a load less than 25% of the total load.

On (Sk. 5) there is a company plate with the characteristics of the engine, which is installed in the Pedrollo pump. It contains all the necessary information about the engine and pump. The characteristics of the pump are not visible.

From the factory plate it can be seen that it is a single-phase motor and it is re-wired for connection with a voltage of 220-230 volts of a 220-230 volt jet with a frequency of 50 hertz. Number of turnovers 2900 per piece. The pressure of the engine to become 0.75 kW or one kinska power (HP). Nominal strum 4 amperes. The capacitance of the capacitor for the selected motor should be 20 microfarads. The capacitor can be used with a working voltage of 450 volts.

Advantages and shortcomings of three-phase motors

Before the override of asynchronous three-phase motors, you can see:

- low price por_vnya z collector dvigunami;

- high arrogance;

- simplicity of construction;

- pratsyyuyut bezperedno vіd merezhі zminny struma.

Up to a few asynchronous motors next to freeze:

- the launching strum, when turned on, is high;

- low pressure coefficient, with small pressures and at idle;

- for smooth regulation of the wrapping frequency, it is necessary to stop the frequency changeover;

- calm down reactive tension, even more often when asynchronous motors are blocked, a connection with a lack of tightness can be blamed for problems with an elastic life.

Advantages and shortcomings of single-phase motors

Prior to the transition of single-phase asynchronous motors, you can see:

- low varity;

- simplicity of construction;

- trivalent term of exploitation;

- high arrogance;

- a robot in the middle of a 220 volt strum without reversing;

- low noise level due to collector engines.

Up to a few single-phase asynchronous motors should be sealed:

- arc high launch jets;

- large dimensions of that vaga;

- obmezheniya range of tension;

- sensitivity to changes in the voltage of life;

- with a smooth regulation of the frequency of the wrap, it is necessary to stop the frequency changeover (for sale, the frequency changeover of single-phase motors).

- it is not possible to vicorate in low idle modes.

Irrespective of the number of shortcomings and the rich successes of the asynchronous motors, they successfully work in the different circles of industrialism, the strong state, and I will try. stink robbing life modern people more comfortable and handy.

Three-phase motor in a single-phase line

There are situations in life, if it is necessary to turn on 220 volts at home by some kind of command. And here you can get food, but what can you do? Vidpovіd - so, if you want to in this situation, you will inevitably spend the strain on the moment on the dvigun shaft. In addition, the cost of asynchronous motors is up to 1-1.5 kW. To start a three-phase dvigun in a single-phase line, it is necessary to reverse the phase from the damage to the first corner (optimally by 120 °). It is possible to achieve this zsuvu, for example, to win the phase control element. The most important element is the capacitor. On (Fig. 6) there is a diagram of the inclusion of a three-phase motor in a single-phase line when the windings are connected to the “star” and “trikutnik”

When starting the dvigun, it is necessary to boost the forces of inertia and calm down. To increase the wrapping moment, it is necessary to install an additional capacitor, which comes to the main circuit only at the time of launch, and after the launch it is necessary to turn it on. With the help of the method best option bude zastosuvannya button SA, scho zamikaetsya, without fixing the position. Press the next button at the moment of supplying the voltage of life and starting capacity Sp. create an additional destruction of the phase. If the engine spins up to nominal speed, the button must be released, and the circuit will have a working capacitor Srab.

Razrahunok of the size of the capacity

The capacitance of the capacitor can be determined by the selection method, starting from a small capacitance and step by step moving to larger capacitances, until the elimination of the second option. And if it is possible to reduce the strum (the lowest value) in the measure and on the working capacitor, then you can choose the most optimal capacity. Vimiryuvannya struma need to be carried out with the right movement. The starting capacity is built up depending on how well the sufficient starting torque is created. The whole process is trivial and laborious. In practice, they often coryste more swedish way. It is a simple way to calculate the capacity, the truth is that the formula gives a better order of numbers, but s її values. І tinker around with your vipadka to get it.

Srab \u003d 66 Pн

De

РН - nominal pressure of the engine kW.

Tsya formula is useful when the windings of a three-phase motor are connected to a tricycle. When using formulas on the skin with 100 W of triphasic motor pressure, you need a capacity of about 7 microfarads.

If the capacitance of the capacitor is increased, lower it is necessary, the engine will overheat, and if the capacitance is less, then the pressure of the engine will be underestimated.

At deyakih vipadkah, krіm working capacity Srab. vikoristovuetsya that starting capacitor Sp. It is necessary to know the place of both condensers, otherwise the engine will not work. On the back of the head, there is a significant amount of capacity, which is necessary for the rotor to wrap around. With parallel inclusion єmnіst Srab and Sp. add up. We also need the nominal value of In. I give information we can look at the company plate, which is attached to the engine.

The rozrahunok of the capacity of the condenser should be carried out fallowly in the form of a connection diagram of a three-phase dvigun. When the windings of the engine are brought to the “star”, the opening of the capacity is carried out according to the following formula:

Srab = 2800 I/U;

At the time of the winding of the motor winding to the "trikutnik", the working capacity is expanded as follows:

Srab = 4800 I/U;

De:

Srab - operating capacity of the capacitor at uF;

I- nominal strum at amperes;

U is the voltage in volts.

The capacitance of the additional starting capacitor is to blame but 2 - 3 times greater than the capacitance of the working one. If, for example, the capacitance of a working capacitor is 70 microfarads, then the starting capacitance of the capacitor can be 70-140 microfarads. What is the sum of 140-210 microfarads.

For three-phase motors with a voltage of up to 1 (kW), it is sufficient to use only a working capacitor Srab, an additional capacitor Sp can not be connected. When choosing a capacitor for a three-phase motor included in a single-phase circuit, it is important to correctly rotate it operating voltage. The operating voltage of the capacitor must be no less than 300 Volts. As a capacitor, the mother works more voltage, in principle, nothing bad will happen, but if you increase the dimensions, and, of course, the price. If the capacitor is vibrated with a lesser working voltage, lower is required, then the capacitor is more likely to vide out of tune and can vibrate. Even more often there are such situations, if there is no capacitor of necessary capacity. Then it is necessary to connect a small capacitor in parallel and sequentially in order to take the necessary capacity. It is necessary to remember what parallel connection number of condensers last day the total capacity changes depending on the formula: 1/C=1/C1+1/C2+1/C3 and so on. Also, do not forget about the working voltage of the capacitor. The voltage on all capacities that are connected in parallel is guilty but not lower than the nominal one. And the voltage on the capacities, which are connected sequentially, on the skin capacitor may be less than the nominal value, but the total amount of voltage must be not lower than the nominal value. I will direct the butt, є two capacitors єmnistyu 60 microfarads with a working voltage of 150 volts leather. When they arrive in sequence, the total capacity is 30 microfarads (to change), and the operating voltage increases to 300 volts. On what, maybe, mustache.

Thanks for showing interest.