Vlashtuvannya grounding budіvel. Installation of grounding electrical installations

What is a piece of grounding?

Most often, the role of a piece earthing worker is a conductor, preparing soil from steel and premises near a horizontal or vertical plane. In such vipadkas, there is a whole group of similar guides, as if they are joining each other. At this time, the earthing worker can be folded. If the electrodes make up the circuit, then there will be a ground circuit.

Why are one type of one vertical and horizontal grounding device used?

In fact, it is not necessary to understand the mind, to that, for example, in another person, it is absolutely unobvious, so that the grounding station of the ground was strictly horizontal. However, it is important that the conductors who establish the grounding or grounding circuit were at the required depth. It is necessary for you to have a good time earthen robot the stench did not take away the daily mechanical ears.

Through those that the surface of the earth on different її plots is not sufficiently even, horizontal grounding is due to follow the surface relief, as far as possible exactly repeating yoga.

So the very vertical electrodes can be installed not vertically, but with a slight impudence, which, in fact, will not directly inject into their work.

Is a horizontal grounding device placed on the yak clay?

Horizontal grounding is best laid at a depth of approximately 0.5 m. As earth ground, the depth is best increased to approximately 1 m.

As a rule, similar grounding devices are installed behind the help of special devices, and there is practically no manual work here. It should be noted that the upper balls of the ground are most often repaired more strongly by the electric stream in the povnyanni with more deep ones.

If you lay a horizontal grounding device close to the surface of the earth, then in which direction the electric strum is running along the ground, we do not pass it evenly, but at a greater depth, such an effect can be reached without winding up and down.

For horizontally installed conductors, the opir is significantly greater than for a parallel conductor with a similar conductor, which is installed in a vertical position. The very reason for the most part of the hour spent electrical installation robots crusted with vertical conductors.

It’s best for you to use vicoristovate glybine vertical electrodes, because the stench of the building is far from good electric strum ball the ground.

How to choose the number of piece earthing machines?

Grounding electrodes, installed in the soil, as well as visnovkas in them, whether they are jumpers, the fault of the mother is minimal allowable expansion:

Round steel - diameter 10 mm;

Round galvanized steel - diameter 6 mm;

Kutova steel - tovshchina police 4 mm;

The overburden for grounding workers from the protection system attached to them from the blisks - 160 mm2;

Smougasta steel - 4 mm, in case of a cut, it should be 48 mm2 (when preparing a grounding main, the span can be no less than 100 mm2, and for grounding with a bliskvkozakhistu - 160 mm2);

Rejected pipes - the thickness of the pipe walls is 3.5 mm.

Why are the minimum allowances calculated?

Indicated other minimum electrical wires for electrical devices in piece systems of grounding are taken as the main rank, for their victories in timchasovy installations, it is possible to resist corrosion by the minds, because stench will not play a major role.

If it is necessary to arrange a grounding system for a permanent installation, then in which case it is necessary to choose a grounding system in such a way that there will be a greater supply of corrosive materials. The best way to repair the negative impact of corrosive processes is round steel. On the right, in the fact that the rose of the metal irzhei without intermediary lie in the surface of the metal, as if it imperceptibly stikates from the earth. Through those that the round area has become the least, it is much more likely to collapse.

In order for the earthing worker to function properly for a long time, for example 40-50 years, for this preparation it is necessary to take the material of a richly large comrade, the minimum value is assigned. For example, if you know how to weigh a few pounds in a friendly way, then it’s not necessary, then the diameter of the grounding machine can be the largest by 2-3 mm. If the soil is vology, then the diameter is to blame but the larger one for the minimum value of the vdvich.

How to install a piece grounding device in the ground?

In the form of the grounded part of the electrical installation, the horizontal exchange of the grounding outbuilding is to be dispersed at the opposite straight lines. Well, if there are not two exchanges, but more, then it’s better to change them one to one.

Tse roblyat with this method, sob yakomoga large area land was conquered rationally. If you install grounding officers one by one, then the stench will be screened one by one, then, their efficiency will be significantly reduced. For the same reasons, one type of one and vertical grounding device is installed on a significant station. Vertical grounding devices should be installed as best as possible on a stand that is at least as expensive as the earthing device itself.

Through those potentials on the surface of the earth, they can not be subdivided evenly, but near the ground, unsafe voltage will be created. In order to eliminate different potentials, the grounding device is prepared in the form of a grid, so that it can be crushed from horizontal elements. For soils, it is necessary to lay a bridle across the electrical installation site. So they follow them one by one for additional help. As a rule, the size of one middle of the removed mesh should be made from 6x6 to 10x10 m.

In addition, in some cases, they have the potential to be used for additional grounding, which is being prepared in the form of concentric rings. It is necessary to place them in the ground and z'ednati from the grounding outbuildings.

The voltage on the surface can be reduced for the grid, only in this fall it’s all the same high mobility of the one that, beyond the boundaries of the net, the possibility of damage by an electric jet will be saved. At zv'yazku z tsim it is necessary to lay additional grounding, the depth of the laying of such can be gradually increased. Such additional structures are also necessary to be connected with the main grounding devices.

How dodatkovo secure the earthing station?

The area of the grounding device and the metal sheet can be shortened with the help of a special insulating fence, as it is installed along the perimeter of the earthing device. The next step is to indicate that the fence can be prepared with a dielectric. Such a pidkhid allows you to prevent the spread of an electric stream on the earth's surface. In addition, fencing with a dielectric allows you to increase the potential of the earthing worker.

Why is it better to make a fence?

For the purpose of this design, it is possible to vicorate any material that does not let the electric stream through, it is also the fault of the mechanical point of the gap, and the electrical power of it is to be no less than 1 MV / m. For this reason, insulators are best used, as they are prepared on a bitumen basis. For example, brizol is brought up to them, which is prepared from the inputs of virobnitstv. Yogo electric mіtsnіst sound more than 20 MV/m.

What problems can be caused by the preparation of a grounding worker?

The most common grounding devices, made of profiled steel, are not satisfied with your wishes, as they are presented to the structures to be grounded. It is permissible, in dry weather it is problematic to achieve the fact that each type of grounding maw is necessary for the conductivity of an electric jet. Difficulty mounting in rocky rocks this type grounding, and in an aggressive medium it is even more difficult to protect them from corrosion and at once reach the necessary level of conductivity of an electric jet. For such types, special designs of piece grounding devices are developed.

Why should a grounding worker be done in areas with dry soils?

For dry areas, such a design is most likely to win. The grounding device is made from cast concrete. Її place below the surface of the earth. The water is filled with such a capacity through a special sunroof.

Such a design has a water-spreading system. Vaughn є vіrіzkami steel pipes, In some є open for the drain of water, which is roztashovuyutsya evenly along all the pipes. Pipes are covered with a ball of material, building clay, for example, with concrete or cement. Swidkіst filtratsії vologi, z kakoyu water permeable through concrete and time into the ground, without intermediary lie down like brand concrete. Correctly poured concrete to allow speeding up the screed, straightening on a regular basis. The view from the concrete chamber is hung up with steel strands.

Yaki famous rice foreign construction of a modern earthing machine?

The main meta of this design is similar to the change in metal capacity and easier placement of the outbuilding in the ground. Grounding for any type of equipment with a thin-walled metal tube (the thickness of the walls is 1-2 mm). At the same time, a nap_zhorst haircut is inserted into it, made from plastic material. However, this hardness is sufficient to be a support for a spring tube with not too thick walls. Tsya authorities allow the grounding man to cross over, as if they are striding on yoga path. In order to maximize the term of service of this earthing device, the tube is made of stainless steel.

On the end of the pipe there is a cone-shaped steel tip, made from natural steel. Vіn appointments so that the tube can be hammered into the ground more easily. Since there is no tip, then the tube can simply be squeezed in breams.

The diameter of this tube should sound to be 15 cm. When the diameter of the core, which is to be pressed into such a tube, sound larger for yoga. The tube is sometimes filled not with a thick core, but with a fluid material, which is harder after the filling. The most common vicarious materials are epoxy resin, polyurethane or elastomer.

However, there is no trace of vicoristing for tsієї mark over that plastic materials, that stench is not enough to create enough mіtsnіst for the walls of the tube, even if you happen to score on a perceptibly large depth - approximately 2.3 m. I know it's hard. The design has a shoulder that rests against the end of the tube, as well as a ledge, which does not only interlock with the inner diameter of the tube itself, but also with a plastic core.

In order to secure electrical safety it is necessary to install a ground loop in the booth or at the reception. The earth is a good conductor, which is negatively charged, and as the body of the hard electrical appliances is connected with this conductor, for the help of vertical grounding, then you can not be afraid of being struck by an electric jet, winding a phase voltage around a turn.

In order to carry out the installation of vertical grounding, which complies with the current rules and standards, it is necessary to familiarize yourself with the basic principles of the correct installation of this method of electrical engineering.

Materials for vertical grounding

As practice has shown, the best vertical grounding device is a steel round shear, which is installed in the ground, without intermediary hitting the object that is being protected. Crim of a steel bar, it is allowed to vicorate as a ground medniy drіt. Ale vrakhovuyuchi high versatility of this material, it is not often vicory as a grounding conductor. One rod is not enough for the safety of a nadiy zahist in the face of an electric strum, so the shearers placed on the sing-stand alone need one for the help of an electric blast.

In order to zdіysniti z'єdnannya shearing among themselves, it is necessary to add fittings, so that they can be welded to the skin grounding device from round steel, and introduced into the booth for connection to electrical appliances and attachments.

The price of a steel shear is small, and for the presence of an electric welding machine, all robots can be vikonated independently. The versatility of stained glass materials in the course of carrying out similar work will also not be too great, to that grounding, like vikonan with steel shears and fittings, does not mean significant financial contributions.

Razrahunok parameters

The first step is to analyze the installation work, it is necessary to set the correct design of the grounding parameters. The area of \u200b\u200bzіtknennya vertical grounding with rock without a middle lie down in the support of the soil.

As a rule, it is located near the pivnіchnyh regions of the country, de grunt freezes on a significant depth, the area of the conductor with the soil may be larger, lower on pivnі, de grunt does not freeze on a depth of 0.5 meters.

When the soil is frozen, the opir sharply increases, which negatively affects the efficiency of the ground loop. Therefore, in order to ensure the proper level of electrical engineering, in the minds of permafrost, installation technologies can be installed, which are introduced into the air.

As if the ground was frozen over, it is necessary to drill on a significant depth, install metal electrodes and sip open the soil earlier.

Vіd breed, in yakіy it is necessary to build grounding, also to deposit the area dotik ґruntu with ґrunt that nursery opir speeches.

The most important support in skelny and stony soil. The length of the vertical grounding device, at which point, will be maximum, in order to ensure the normal passage of the electric stream in the rock. In such minds, the installation of vertical grounding is the only way to improve the electrical protection of the object. The most optimal option for installing an electrical installation in such minds is the installation of a special vibrator, which allows you to easily install a shear in a rocky or stony ground.

If it is necessary to install grounding in black soil and peat, then for the provision of normal grounding, it is enough to ground the electrode to a depth of 1.5 meters.

The diameter of the vertical grounding device must not be less than 16 mm. Sound like a vertical shear for grounding, metal fittings with a diameter of 18 - 20 mm are beaten.

Installation

After the type of soil is determined, the installation of grounding is planned, it is possible to proceed before the installation of shears.

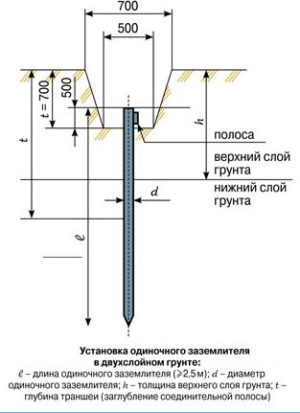

The first step is to install the shears into the ground, it is necessary to take the upper ball of soil to a depth of at least 0.5 meters. Sound such a trench to fight along the perimeter of life. Vіdstan mіzh vertical earthing machines can be no more than 5 meters. The number of vertical grounding contractors is not very important to cheer up, as if to add a deep trench length to “5”. For example, with a deep trench of 50 meters, the number of vertical grounding devices in the warehouse is 10 pieces.

In order to increase the penetration of shears at the soil to the required depth, you can drive them in for help with a sledgehammer. If the soil is soft, and the length of the shearing does not exceed 3 meters, then manual installation will not take a lot of time and effort. For the convenience of a distant installation, it is necessary to install vertical shears in the trench in such a way that the stench hangs from the bottom at a height of 10 - 20 cm.

If you want to finish the soil with stones, you can use a hammer with a special nozzle for installing vertical shears.

In the original way of installation, they fit in the same way, as a tractor-excavator of the Pivnik type. The hydraulic drive of lifting with a bucket allows, with sufficient susills, to pour on the vertically placed shear, so that the remaining part of the wind is wound around the stoney soil.

After the installation of all vertical grounding devices, they are connected between themselves by horizontally spreading bars of reinforcement.

The diameter of the horizontally folded shearings must be no less than 10 cm, otherwise it will not be possible to show the support on the necessary level.

The back of the haircut is possible with a steel line. The width of the stitch can be no less than 48 mm, and the width of the metal - no less than 4 mm. Zvaryuvannya can be vikonan yakіsno, so that at the places of zadnannya the metal does not settle the process of corrosion, which can be signifi- cantly settled by strums, which can pass through the zvarny seam.

To ensure the continuity of the termination of the electric stream along the conductor, follow the safety along the entire perimeter of the electrical circuit, rely on vertical grounding, which is 4 Ohm. It is impossible to reach such an ideal indicator of support, for example, the value of up to 10 ohms, without compromising the power of vertical grounding.

As soon as the installation of an electrical installation is to be put into operation, it is necessary to remove the vertical shear, it is necessary to pour a significant amount of water. In this way, we are trying to establish the structure of the soil, which is the most efficient way to transfer the electric potential from the metal shavings of the earth.

Self-installed

Vertical grounding electrodes can be installed independently. When installing, it is necessary to know the warehouse of the soil, in order to estimate the approximate depth of installation of working electrodes. For installation of grounding, it is necessary to bring a zvaryuvalny apparatus that required quantity electrodes in order to make vertical and horizontal grounding devices.

For the production of metals, it is not recommended to vicorize different zatiskachi and other threads. In the course of such a year, such a month can significantly worsen the conductivity of a deli. electric lansyug which will negatively affect the efficiency of the ground loop. How the soil does not freeze through winter hour to a depth of more than 0.5 meters, and not skelnym or kam'yanistim, it is possible to win a round shearing no more than 1.5 meters.

For the unfriendly minds of the installation of grounding, the depth of the placement of the shearing can become less than 3 meters, and the other way around them can be changed to 4 meters. It is not recommended to change between electrodes;

Since there is no way to deal with the installation of grounding on your own, then you can turn to specialized firms, yak short term install vertical grounding on the spacer, which lies close to the booth. Irrespective of those who spend money on such servants, the savings can be significant for an hour. If this resource is more important, then it is better to entrust the work to professionals.

The grounding of the buildings and other parts of the underground and butt electrical installations, which do not change the sound under the pressure, allows you to bring in an electric jet at the ground. Tse transferred by the Rules safe operation electrical installations and expandable on the flanges of the supporting insulators, shields and control cabinets, handles of the drives of the switches, housings of the winding transformers, charging devices and other equipment. Installation of a grounding system, transferring the installation of grounding pins and attaching grounding conductors to them, which are connected to the electrical housings.

The grounding of the charging apparatus, which is a stationary installation, is dependent on the method of safe operation. The main vimogi to the grounding of the offensive:

- All non-permanent parts of electric welding installations and one second visnovok are grounded.

- Grounding equipment may be equipped with a special contact (type of bolt or stud), suitable for grounding.

- The grounding bolt is to blame buti with a contact maydanchik, marked with a special grounding sign.

- Subsequently, the earthing of a number of installations is blocked: for the skin maє buti, an additional point of entry was transferred.

Portable brewery automatic settings the kind of automati that are connected to the merezhі snake struma over 42 V (and more than 110 V DC), also equipped with grounding contacts. As a grounding (grounding) for installation, it cannot be blocked or the installation of grounding is difficult, the electrical supply is due to the mother of the ELV (adaptation of the electrical connection).

Grounding can be victorious and for the power of a blissful cossackist.

For objects that are powered by a step-down transformer with a dead-earthed neutral and a voltage on secondary winding 380/220, re-grounding dominate on the introduced. With the help of the ground loop, zgіdno z PUE, is not guilty of being larger than 10 ohms. In order to secure such parameters, it is necessary to use grounding conductors with a large contact area and garnier conduction. The top surface of the wine is cleaned with a glass of olії and farbi. Attachments for whom:

- pipelines from metal (krim is quiet, which is connected with combustible sources and gases);

- metal sheaths of cables;

- casing pipes;

- foundation elements.

Scheme for installation of a grounding circuit in such a situation can transfer the subway to the grounding main. For the arrival of grounding conductors to the grounding conductors, a zvaryuvannya is made. For this purpose, the seam is to blame for the buti vdvіchі wider for the rectangular shape of the conductor (at the crossbar) and six times - round. It’s impossible to make a vicorous brew - clamps are stuck, yak, like a brew seam, protect bitumen from corrosion with a ball. Before applying the clamps, the surface of the natural earthing machine is to be cleaned up here.

In vibro-insecure applications, natural grounding can be more vicarious as an additive. The main maє buti grounding piece, vikonan vіdpovіdno up to PUE.

The internal ground loop is fastened with anchor bolts without a middle to the wall. At the places of the shackle, with cables or pipelines, they transfer protection from pipes. Admissions high level water resistance and acidity, the internal grounding circuit is to be fixed on supports on a stand 100 mm from the wall.

Different types of grounding

With presence natural grounding the installation of the outer ground loop is to be carried out, until such a connection is made to the connections and the electrical control terminals.

Piece grounding can be implemented from vertical or horizontal grounding devices. For vertical vicorist pipes, pipes are made of steel or coils, as if they are connected one by one, as a result of which the contour is established. Suitable elements for horizontal grounding: zastosovuetsya for this metal swag not less than 4 mm or round overcut fittings with a diameter of 10 mm.

Horizontal earthing machines can be used to look like metal smugs, which are laid at the bottom of pits, preparing the foundation for everyday life. Smugi is roztashovuyutsya in such a rank, so that the largest surface of the bula is oriented at the edge of the earth. Peretin smug - 30 × 4 mm, round steel fittings with a diameter of 12 mm can be twisted.

It is not allowed to scrape aluminum for laying buried grounding, the shards of this metal will easily crumble at the ground due to electrocorrosion.

There, de installation of horizontal grounding is impossible (for example, through land plots, free of asphalt and other communications), the technology of clay grounding is being implemented. When tsimu at one point in the ground in a different way metal shearings are introduced: the end of the dermal step comes down from the front, establishing the ground from the great contact area.

How to win horizontally grounded

The technology of grounding installation is simple. Vikoristovuetsya for vikonannya robit grinder with a stake for metal, zvaryuvannya, a sledgehammer and a metal shield for cleaning the place of zvaryuvannya. The whole process consists of such points.

- Procurement required materials. Need:

- smuga from the same material 40 × 4 mm or round drill (reinforcement) with a diameter of 10 mm;

- hot-zinc coils of 2.5 m each (with 50 × 50 × 5 mm peretina - 3-4 pcs).

- We are compiling a project, so that in the adjacent territory there is enough space for the distribution of vertical electric wires on the stand, so that we can move the water up to 2.5 m.

- A trench is swarming with a width of about 400 mm and a sag of 700-800 mm.

- In some places, the coils with sharpened tops are hammered with a sledgehammer, covering the surface of 200 mm.

- Welded to the ground loop: smuga metal is welded to the tops, to be washed above the ground.

- Zvaryuetsya grounding with a drotom or a bus, laid up to rose under the shield abo shafi keruvannya.

- Zvaryuvannya smugi grounding with kutochki and good drіt is covered with bituminous mastic for protection against corrosion.

- All the elements are attached to the earth, as if we were to be rammed.

- The earthing opir is vimiryuetsya.

- If the result is changed by 4 ohms, it is necessary to add one more vertical element, which will fit into the other design.

Installation of vertical clay earthing

Crimea saves space, deep grounding can have one more thing: for the contact with the lower, deep and rich ground water balls of the soil, a good conductivity is reached.

Do-it-yourself grounding installation is possible in a different way. Choose to lie in the power of the ґruntu in tsіy mіstsevostі:

- for fluffy rocks, there is an indentation, screwing in, that clogging of the electrodes, which are made up of a few shearings;

- at shchіlnі that zlі ґrunti elektrodi zanuryuyuyutsya by the method of clogging or vibrozanurennya;

- in rocky rocks, the electrodes are buried in a specially drilled hole.

Electrodes, fallow in the soil, vicorous are different. The stench is square, the hood is round. Retin їх is selected for soft soils at the boundary of 12 - 14 mm (for example, the driving depth is sufficient up to 6 m), for deep soils that significant driving depth (more than 10 m) the cutting of the electrodes may become 16 - 20 mm. For clay hammering of vicorist, special vibrators are used;

As for the power of the ground, nothing is known, when installing clay grounding it is so.

- Prepare the electrodes of the necessary supply.

- Clog the first earthing pipe and win the earthing support.

- Up to the upper end of the clogged windpipe, the offensive element is welded and hammered.

- I am starting to carry out the reconciliation in such a way that the docks continue, the docks do not take away the necessary value of the grounding support.

- To the upper end of the rotten electrode, weld the bus or dry, the other end of which is to start at the rozpodilnu shaf or shield.