How to determine the diameter of the pipe for scorching with primus and natural circulation

For an ideal design of a scorching system, it is important not only, but also to correctly open the pipe diameter.

For an ideal design of a scorching system, it is important not only, but also to correctly open the pipe diameter.

The very parameter determines the throughput of the building of the pipe, indicating the volume of heat transfer, which can be transported through it in one hour. The diameter of the pipes directly affects the length of the pipeline and it can be “decoupled”, and also determines the number of scorched radiators, which can potentially be connected to the system. The heat loss can be predicted by spiraling on the diameter of the pipes.

All pipes for scorching systems can be mentally divided into two types:

- metal: black metal, copper, brass, bronze;

- polymers: metal-plastic, polyethylene, polypropylene.

metal plastic pipes easy to install, resistant to temperatures that rise for a day up to 130 degrees, the stench of a gnuchka can be spread behind furniture. Polyethylene pipes are stretched when heated, which is why they are reinforced with additional reinforcement and compensation loops. Be it plastic pipes, they don’t make noise, which is one of them.

do not compromise with metal-plastic analogues, but for a bagatma their characteristics are reversed. The term of service of a copper scorching system reaches 100 years and fahivtsy, making this material ideal for a scorching system. Medium may have a high thermal conductivity, which is good for a heating system, but not so good in other scorching systems. І mid - dosit expensive material. Stainless steel is cheap for copper, but it is important to mount it, while not having the necessary thermal conductivity and bending.

If any of the refurbished materials may have their own advantages and shortcomings, it is better to use pipes made of PVC and polypropylene, shards of stench are pleasant to high temperatures.

See scorching systems

Opaluval systems are centralized and individual. IN central system scorching, like vicorist at rich tops, the pressure can rise up to 16 atmospheres at the time of cleaning the pipeline. In an individual system, like in private houses and cottages, the pressure does not exceed 2-3 atmospheres. Crimea, scorching systems are single-tube and two-tube, with a primus stove natural circulation. Zrozumіlo, trumpet the fault of the confirmation of the specific system of scorching.

Primus scorching system

for the installation of a primus system and maє buti malim, and the axis of what:

- with a smaller diameter of pipes for scorching, a smaller amount of heat transfer is needed, which heats up, which gives savings in savings per hour;

— the flow of heat transfer in the system is lesser, lesser pipes are cut;

- Installation of pipes of small diameter is easier to carry out;

— pipeline of small diameter economically viable.

Diameter of pipes and KKD scorching systems

Efficient functioning of the scorching system is only guaranteed by the correct design of the pipeline. Even at the planning stage, it is necessary to shorten the heat losses, otherwise you will not be completely efficient and cope with your tasks. An economical system with a high CCD is created only by improving the necessary aspects: the physical and chemical characteristics of the material, and the diameter of the pipes.

See pipe diameters

1) internal diameter (є the main parameter that determines the size of the fiber);

2) actual diameter (gives classification of pipes):

- Minimum diameter (5-102 mm);

- Medium (102-406 mm);

- Great (406 mm and more);

3) smart diameter (rounded to the nearest whole number of the value of the diameter, expressed in inches).

The material from which the pipe is made determines the difference between the inner and outer diameter of the pipe. Zovnіshnіy diametr zavzhda suvoro vrakhovuєtsya under the hour of installation of the system of scorching, shards from the new deposit vibіr krіplen. The internal diameter is the main criterion for choosing pipes for the system.

Pіdbіr pipe diameter for a private cottage stale in the way that heat transfer is supplied to the system. If the cottage is connected to the central highway, then the renovations are carried out the same way, as when installing the pipeline in the apartment. As for the cottage equipment, the diameter of the pipes is stale according to the scorching scheme and the material. For example, natural circulation will require one diameter, and primus - another.

How to unravel the diameter of the scorched pipes

On the choice of the diameter of the pipes in the line, the material is chosen, especially the distribution Opal system, type of heat transfer, pressure of water in the system and speed of heat transfer in the system.

For the formula, for which the pipe diameter is insured, the following must be insured:

- Selected breeding scheme;

- Outlet diameter of the inlet-outlet pipe;

- Fluidity of heat transfer in the system (ideal would be an interval of 0.3 to 0.7 m/s).

- temperature difference between supply and return in the scorching system, so that the cooling of heat transfer is increased;

- Coefficient of pipe support (supported by a picker);

— required quantity heat.

Professional rozrahunki diameter pipes scorched dosit folded, let them be engaged in fahivtsі-heat engineering. Let's introduce a simplified formula:

D=√354∙(0.86∙Q:∆t):V,

de D – pipe diameter in centimeters;

∆t - temperature difference in degrees Celsius (supply-return for a two-pipe scorching system);

Q - navantazhennya on a specific lot of the system at kilowatts;

V - speed of heat transfer in meters per second.

When designing the scorching, follow the lines in the boiler inlet-outlet. The diameter of the pipes for scorching is due to smaller ones, the lower diameter, and on the cob space of the yogo to slab with metal, so that the entire pipeline is built from polymer pipes. For example, if a central pipe with a diameter of 1 inch is laid in front of the boiler, then the stripping should be done with pipes with a diameter of ¾ inch, and then a pipe with a diameter of ½ inch should be led into the neck of the remaining fitting. Up to rozrahunkіv pipe diameter for singing dotsilnіshe zaluchi fahivtsіv.

Important! In the pursuit of profitability, it is not possible to install pipes of smaller diameter, lower diameters in case of re-roofing, otherwise the entire scorching system will be noisy and ineffective. So it’s worth remembering that with an increase in the diameter of the pipes, the efficiency of the scorching system increases. The unrealistically large diameter of the pipes reduces the pressure on the system, which minimizes the heat at the booth.

Most of the pardons during the installation of the scorching system cannot be corrected vibirkovo, and the entire system must be redone, to which the fireworks may be corrected. Fahіvtsі dopomozhut to design the scorching system most rationally, and in this way include the need to reinstall the system and vitrates, which are connected with cym.

When installing the system for heating the booth, it is important to consider the diameter of the pipes for scorching. Vіn dopomozhe niknuti zayvih vtrat heat and vitrat energy.

Krіm tsgogo, the diameter of the pipe is determined by its dimensions, yakі sled vrahovuvat pіd h plonuvannya design primіschen.

About hydraulic sprayer for scorch pipes

In order to unravel the diameter of the scorched pipes for a house or an apartment, it is necessary to know the main parameters, tse:

- material, from which stench was prepared (for example,);

- internal diameter of the pipes themselves;

- similar parameter of fittings and fittings;

- the nominal value of the internal diameter;

- tovshchina of walls at pipes.

Follow the memory, what is not correct choice diameter for pipes and non-primed yogo zbіlshennya, with the method of increasing the area of thermal ventilation more, obov'yazkovo made a vice in the system of thermal input to fall.

Get respect!

Moreover i neobhіdny gіdravlіchny rozrahunok dvotrubnoї sistemi scorched, priznacheny for pіdboru such values dіametra vsіh dіlyanok conduit at yakih in cutaneous of tsirkulyatsіynih kіlets vise scho peremіschaє rozrahunkovu Quantity teplonosіya (in odinitsyu hour) perevischuvatime 10 vіdsotkіv vtrati vise vnaslіdok gіdravlіchnogo support.

The losses in the circulation circuits are divided into losses, which are blamed on the friction, and also the losses on the mass supports.

The formula for determining the diameter of the pipeline

Professіyny rozrahunok diametrіv pipes singed foldable and accessible only to fahіvtsam-heat engineers, so let me tell you about the simple scheme.

With such a calculation, the formula for the designation of the expansion of scorch pipes is as follows:

D = √354∙(0.86∙Q:∆t):V

De letters mean:

- D - pipe diameter, centimeters;

- Q - the charge per square foot of the system, in kilowatts;

- ∆t is the temperature difference at the supply and the return line, in degrees Celsius;

- V - speed, yak maє teplonosіy, in meters per second.

It should be noted that at the supply the standard water temperature is not guilty but less than 90º, at the return of the heat carrier it reaches up to 65/70º. Mean the value of ∆t is 20º.

Rozrahunok navantazhennia, so that the necessary thermal exhaustion of the system

Schob signify minimally necessary tightness opal system, you can vicorate this simple formula: Qt = V∙∆t∙K:860

- De symbols mean:

Qt - required thermal exhaustion, In kilowatts per year; - V - volume of room, which is heated (height, depth, width), in cubic meters;

- ∆t- difference between the temperature of the outside air required temperature in the host, in degrees Celsius;

- K - coefficient of heat consumption budіvlі;

- 860 means conversion from kW/year.

The coefficient of heat loss will be deposited in this type, as well as heat insulation.

If the heating of the scorched pipes is carried out, you can use such simple values for different types wake up call:

- K, equal 3/4 - life, which does not have thermal insulation (the construction is simplified from wood or corrugated metal sheets);

- K, vіdpovіdniy 2/2.9 - a small step of thermal insulation (the design of the building is simple, for example - single masonry with pins, simple design of covering that window);

- Dorіvnyuє 1 / 1.9 - the average level of thermal insulation (the design will be standard, for example - hanging masonry with chains, a small number of windows, standard covering);

- K, equal 0.6/0.9 – high thermal insulation equal (the design of the building is reduced, stone walls can be used for underwire thermal insulation, a small number of vicons, which can be used for underwire frames, the base of the underlayment is insulated, and equipped with yakish thermal insulation).

If you need a change in the diameter of the pipe for scorching, the difference between the current temperature will be checked and the temperature you need in the premises, it will be calculated, depending on the climate in your space and that level of comfort, as you plan to take the system off.

For example, it is possible to use a bed with a height of 3 m, a length of 5 m and a width of 3 m.

The average winter temperature in Podmoskov'ї, depending on the special tables, is -28º. She and operative. Let's wait a bit, so that the temperature of +20 in the rooms is comfortable. The same value for ∆t: 28+20=48º.

Value Up to 0.9 is acceptable.

Substitute all values in the formula: Qt=45∙48∙0.9:860. By changing the calculation, we take into account the necessary pressure of the opal system in this application: 2.26 kW/year.

Heat transfer rate

Get respect!

The minimum level of speed, as the mother of the heat-bearing one is to blame, is 0.2 / 0.25 m / s.

If the speed is less, then it starts to be seen again from the heat transfer, but it will lead to the establishment in the system of repeated traffic jams.

Lastly, it may be a frequent waste of practice of scorching.

The upper level of the heat transfer rate can be stored 0.6/1.5m/sec. How to reach out upper threshold Shvidkіst, tse allows you to eliminate hydraulic noise from the system. 1.5m/sec. and is accepted as the required value.

Now, knowing all the values we need, we introduce them to the final formula: D = √354∙(0.86∙2.26:20):1.5. At the result of our calculations, we take a clear figure for the inner diameter of pipes 12 mm.

Table of designation of the internal diameter of pipes.

Zvichayno, planning the system of scorching - rozrahunok pipe diameter best zdіysnyuvati, koristuyuchis special table, so that all the numbers and formulas you can not remember. The table clearly shows the parameters, how much more heat transfer, the specific scheme of distribution of the pipeline, the technical characteristics of the heating devices and other.

Therefore, it is necessary to use a table with a table, conducting a pipe + diameter for singing, to the fact that the skin from specific scorching systems can bind it to accessories and work on a specific heat transfer agent - water, oil, antifreeze. Crimson, table and vrakhovu і type of circulation: piece natural.

The scorching of a private booth is a folding structure, which is made up of pipelines and impersonal fittings. In order to create such a system, like warming the booths, without spending money on the wind in the process of exploitation (the one at the installation stage), all the elements of the system are to be optimized, properly selected and supplied to the needs of the booth in heat one to one.

The diameter of the trumpet varto pіdbirati with the marriage of rich mindsFor the correct expansion of the diameter of the pipes, they are taken to respect the total cost in the premises during the coldest winter period. Vihodyachi z thogo, counted

- number of blocks in the skin radiator.

On the diameter of the pipeline it is also poured:

- Distribution type (single or double pipe)

- Circulation method (primus stove, self-fueled)

Boiler

If there is a need, when a cauldron is installed, it is supplied with gas, then a gas-fired boiler in a private booth is unequivocally selected as the most economical one. Rozrahunok potuzhnostі boiler vykonuєtsya vіdsotkovomu spіvvіdnoshenі 1KW. year per 10 sq. square meters with a height of 3 meters.

Scorching boiler without a middle element for the expansion of the diameter of the pipelineOn the vibrator of the pressure of the boiler, also pour in:

- Yakіst paleva (rozrahunok vykonuvavsya vikoristannya gas);

- Heat losses are allowed, like a cauldron for heating on a deakіy vіdstanі vіd house. At the same time, the thermal insulation of pipelines is not sufficient;

- Weak thermal insulation of walls.

- Vykoristanya hot pobutovyh minds. The two-circuit boiler, which is selected for supplying hot water, is to blame for the exhaustion;

- Slid vrakhovuvati and those who collect pressure from gas pipelines inevitably fall.

All vishchezgadanі factors zmushyuyut vikoristovuvat obladnannya intensity in the second or two times greater, lower is necessary for autonomous scorching at home.

Water supply to the boiler: natural two-pipe scorching in Leningrad

Self-priming supply of water to the boiler is charged for centralized water supply. Ale, as a zabudovnik, we take water from the well individually;

A circulation pump is installed in the heating system, which optimizes the heat transfer rate, and ensures safe turning of the heat into the boiler. the problem of overcoming traffic jams, as they are constantly running out of heat transfer. It is recommended to choose a self-adjusting pump with a wet rotor, which is in contact with the heat carrier during operation, for a private booth system. The whole pump works silently, the building itself is made to change the operation of the boiler, the wines are economical and long-term. Yoga tightness and KKD is enough for a cottage.

Manometry allows control of the vice.

The control of the grip in the system of scorching is obov'azkovym, so that at any moment it can be possible and you need to really understand the working grip.Optimum for a home scorching system can be a buti press at a second-two atm. Stribok vise up to 3 atm. Building rose cauldron, pipelines. In order to avoid a sharp displacement of the vice in the scorching system, after moving the pressure of the water, an expansion tank is installed at the exit from the boiler.

Heat conduit at the apartment house: how to choose pipes according to the outer and inner diameter of the sleeve for the radiator

The system for heating the booth does not have the correct choice of pipe, which is the flow of heat. Type of diameter to deposit

- Throughput building pipeline,

- how many waters to be in the opiate circuit at one hour, i, vіdpovіdno, teploviddacha;

- a vice of water at the contour.

Let's look at it, how to tear it up correct system heating with primus circulation, most suitable for scorching in a private booth. Vibrating pipes for the opal circuit, following one factor: copper and plastic pipes are marked according to the outer diameter, and in technical characteristics steel and metal-plastic mills - internal re-cutting is prescribed. This factor is of greatest importance in case of re-roofing of diameters and installation of pipelines. The diameter of the pipe for the scorching of the zamіsky booth is not easy to choose, as if under the hand of the heating engineer.

The diameter of the scorched pipes is important during installation and refurbishment of the systemHow are the pipes for connection wet booth to the centralized heating main, then the diameter of the pipes for scorching is taken the same as in the apartments of richly-topped houses.

Alezovsіm in a different way, the diameter of the pipe is secured for scorching a private booth. It is important to remember thate on the entire length of the heat pipeselect for scorching

blow one roar. On the singing plots, the docks of the world are cleared, their lanes are changing.

The formula for rozrahunka pipe diameter for scorching a private booth

Rozrahunok vykonuetsya for the formula

Formula for rozrahunka pipe diameter for singingD-pipe diameter, in millimeters

∆t° - temperature difference (between water, which is supplied and turned back into the boiler), indicated in degrees Celsius (Co);

Q - the amount of thermal energy required for heating the room in kilowatts, and previously insured by us;

V - speed of heat transfer m / s - is selected from the singing range.

Based on this formula, for simplicity, calculate the created data that allow you to expand the diameter of the pipe.

The list of data (below) shows the values for pipes made of polypropylene, which is why it is more and more often used for the scorching contour. Based on this, determine the diameter required for the given heating system. The rosy color has seen the optimal flow of water movement - carrying heat. If you are planning to install steel or metal-plastic pipes, then you may need to upgrade the pipes.

We can see how the heat carrier is moving near the circuit from the primus circulation. She is working for the help of a pump, a collector, and a carrier of thermal energy. If you install pipes with a smaller diameter, then the intensity of the flow of hot water will be greater, it will be more efficient to turn the pipeline around and turn into a boiler unit. Vіdpovіdno, shirshij trupoprovіd upovіlnіt ruh teplonosіya.

The thin pipe is grooved for more fluid circulation and heat transferSecrets of the installation of the scorched riser: vikoristanny polypropylene pipes 25 mm

The scorching circuit is installed with a pipeline with a smaller diameter for the most common reasons:

- Chim thin trumpet, Tim lower price;

- At for critical installation the stench doesn’t fall so close to the vіchі, but when it’s closed, there’s less depth in the strobes.

- The smaller the diameter of the pipes for scorching, the less heat is present in the system. Tse to bring to the economy a pale.

The temperature of heat transfer in the scorching system should be deposited as well as the flow of heat transfer through the pipeline.

How to carry out a rozrahunok zgidno with an installed boiler:

On the back, it’s obvious that the pipe is needed for the winding of the boiler to the first opening in the booth. Admissible, dorivnyuє 38 kW. According to the distribution, which shows this ostentatious display, we pass to clitins, stuffed with erysipelas and marveling, as if the diameter of the pipes for scorching a private booth is given to these zones. It is obvious that the pipes are 40 and 50 mm. Choose less, tobto 40 mm. The diameter of the pipe for the scorching system is chosen by the right specialist at your right hand.

Dali following the pipeline to the booth. For example, two on top. There is more heat on the lower surface of the clay, Let's assume that 20 kW are clayed on the first surface and 18 are transferred to the other one. According to the table, it is shown that the heat transfer rate is 32 mm.

On the skin version, the pipeline is again divided into two veins. Taken, 10kW on the first version and 9 on the other. Z table bachimo, scho to the parameters of the pipe 25 mm. On the skin version, two wings. The new value of heat is subdivided by two and as a result, 5 and 4.5 kW come out. Dali follows the pipeline to the room, and the heat supply is 5 kW. The diameter is reduced to 20 mm. But as a show of practical advice, switch to the "twenty" may be less sense for the mind to reduce heat up to 3 kW. Zvorotnya vykonuєtsya in this very order.

The number of sections of the radiator of scorched fires extending from the area of \u200b\u200bthe fireplace, where the radiators are installed, and spiraling on the passport data of the radiators, in which the tightness of the sections is registered, is being installed.

WATCH VIDEO

At the end, tell me about those who are scorched dacha booth don't exercise regularly. Yogo turn on only one thing, if people change at the booth. І in the winter period, there is a risk of freezing of the opal circuit, opening of pipes and radiators. In order not to happen, they pour into the cauldron, which, moving with water, lowers the temperature and freezes, in the middle it protects the steel knots of the scorching system from corrosion. Before the speech, the polypropylene pipes of the building are expanded, which protects them from the rise of frostbite, so when organizing the scorching, the fire is hoped for by itself this type pipelines The diameter of the pipe for scorching is to blame for all the help of the system.

In the article, we can look at the system from the primus circulation. The stench of heat transfer is ensured by a permanently working circulation pump. When choosing the diameter of the pipes for scorching, it should be taken into account that the main task is to ensure the delivery of the necessary amount of heat to the heating devices - radiators or registers. The following data will be required for the rozrahunka:

- Zagalnі teplovtravit house chi apartments.

- Tension scorching accessories(radiators) at the skin room.

- Pipeline length.

- The method of raising the system (one-pipe, two-pipe, with primus or natural circulation).

So, before that, how to proceed to the rebuilding of the diameters of the pipes, you should take into account the hot waste of heat, you will need to rebuild it. It is also necessary to designate by the method of breeding. For these tributes, you draw up a scheme and then you don’t even proceed to the rozrahunka.

What else do you need to respect. For those that are marked with polypropylene and copper pipes outer diameter, And the internal ones are calculated (take away the cost of the wall). In steel and metal-plastic, when marking, an internal rozmіr is affixed. So do not forget the qiu "dribnitsa".

How to choose the diameter of the scorched pipe

Understandable. It is important for us to deliver a certain amount of heat to the radiators and reach equal heating of the radiators. In systems with primus circulation, it is necessary to use additional pipes, heat transfer and a pump. As a matter of principle, everything that we need is to “drive away” a lot of heat for an hour. There are two options here: put pipes of a smaller diameter and supply heat with more airflow, or build a system with a larger cut, but with a lesser intensity of movement. Call to choose the first option. І axis why:

So, if it’s the same number of diameters and the same amount of heat, it’s unreasonable to deliver them, just to take in one and the same. To this end, special tables were drawn up, which show the necessary amount of heat, the speed of heat transfer and temperature indications of the robotic system, indicating a possible expansion. Therefore, for the designation of pipe resection in the scorching system, you need to know the table and select the appropriate resection according to it.

The diameter of the pipes for scorching was carried out according to such a formula (you can check for the fires). Then the redeemed values were recorded in the table.

D - tapping diameter of the pipeline, mm

∆t° - temperature delta (difference in supply and return), °С

Q - the amount of heat required for heating the system, kW - we determine the amount of heat required for heating

V - speed of heat transfer, m / s - is selected from the singing range.

In systems of individual scorching, the speed of heat transfer can be from 0.2 to 1.5 m/s. According to the operating conditions, it is known that the optimal speed is between 0.3 m/s - 0.7 m/s. As the heat-carrier is collapsing more, the traffic jams are blamed, as the sound of the noise is growing stronger. The optimal range of widths and choose from the table. Tables are broken down for different types pipes: metal, polypropylene, metal-plastic, copper. Covered values for standard operating modes: high and medium temperatures. Schob process pіdboru buv zrozumіlіshim, razberemo konkretnі butt.

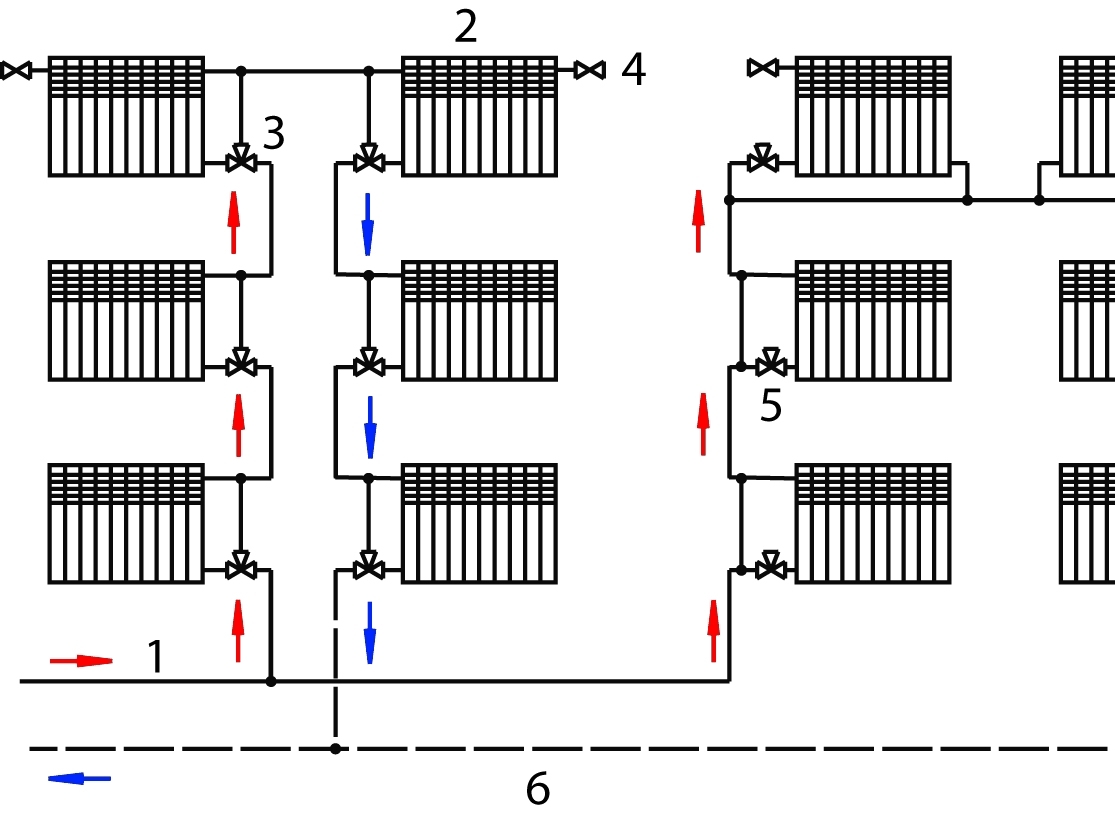

Rozrahunok for two-pipe system

Є double-surfaced booth with scorched two wings on the skin surface. Polypropylene virobi are vikorated, operating mode 80/60 with a temperature delta of 20 °C. The heat consumption of the booth is 38 kW of thermal energy. On the first one, 20 kW fall on top, on the other 18 kW. The diagram is shown below.

Two-pipe scheme for singing a two-top booth. Right wing (press for better expansion)

Two-pipe scheme for singing a two-top booth. Lіve wing (press to increase the expansion)

On the right is a table, for which the diameter is significant. The Rozheva region is the zone of optimal heat flow.

Table for rozrahunka diameter polypropylene pipes scorched. Operation mode 80/60 with a temperature delta of 20 ° C (press to increase the size)

Rozpochinaemo rozrahunok.

- Apparently, it is necessary to beat the pipe at the distance from the cauldron until the first stripping. Through tsyu dіlyanku to pass all the heat, then to pass the entire volume of heat 38 kW. The table has a prominent row, along which it reaches the zone tinted with erysipelas and rises uphill. Bachimo, two diameters fit: 40 mm, 50 mm. We choose the smaller one for the smarter ones - 40 mm.

- Znovemosya to the scheme. There, de potіk is distributed 20 kW go to the 1st overhead, 18 kW break on the 2nd overhead. The tables have double rows, which means that the pipes are cut. To come out, that the offending needles are bred with a diameter of 32 mm.

- The leather from the contours is subdivided into two needles with equal tensions. On the first version, right-handed and left-handed, 10 kW each (20 kW / 2 = 10 kW), on the other, 9 kW each (18 kW / 2) \u003d 9 kW). According to the table, we know the average value of these cutters: 25 mm. This rosemir victorious and nadal until the moment when thermal expansion not change to 5 kW (it can be seen from the tables). Dali go already crossbar 20 mm. On the first one, turn by 20 mm after the other radiator (to marvel at the vanity), on the other - after the third one. There is one amendment to this point, made by the accumulated certificate - rather, go by 20 mm for a charge of 3 kW.

Mustache. Diameter for two-pipe system of insurance. For the return, the peretina is not opened, but the opening is spun with the same pipes, as is the supply. Methodology, spodіvaєmos, zrozumila. It will not be easy to carry out a similar investigation for the visibility of all holidays. If you sing victorious and other trumpets, you will need other tables that are insured for the material you need. You can practice on this system, but for the mode of average temperatures 75/60 and delta 15°C (the table is expanded below).

Table for rozrahunka diameter polypropylene pipes singed. Working mode 75/60 and delta 15 °C (press to increase the size)

Designation of pipe diameter for a single-pipe system with primus circulation

The principle is left by itself, the methodology is changed. Let's take a look at another table for designating pipe diameters with a different principle for entering data. In them, the optimal zone of tightness of the flow of heat is fetched in black color, the value of tightness is not in the column on the side, but brought in to the field. Therefore, the process itself is a little less.

According to this table, it is possible internal diameter of pipes for simple one on top of those six radiators, connected in series. Rozpochinaemo rozrahunok:

Once again, pay attention to the fact that internal diameters are indicated in the tables. According to them, you can know the marking of pipes from the required material.

Well, it’s a problem for them, how to open the diameter of the trumpet of scorching, but it’s not guilty. Mustache is reasonable. But this is true for polypropylene and metal-plastic fibers - they have low thermal conductivity and insignificant penetration through the walls; On the right - metal - steel, stainless steel and aluminium. If the length of the pipeline is significant, then the flow through the surface will be significant.

Peculiarities of cutting the cut of metal pipes

For great scorching systems with pipes made of metal, it is necessary to protect the heat loss through the walls. Spend not so big, but with a great length, they can lead to the fact that the temperature on the remaining radiators will be even low due to the wrong choice of diameter.

It is possible to use it for a steel pipe 40 mm from a 1.4 mm thick wall. Spend money on this formula:

q \u003d k * 3.14 * (tv-tp)

q - heat consumption of a pipe meter,

k - linear heat transfer coefficient (for pipe lines, set to 0.272 W * m / s);

tv - water temperature at the pipe - 80 ° С;

tp - the temperature at the place of application is 22°C.

Substituting the value we take:

q = 0.272 * 3.15 * (80-22) = 49 W/s

You can see that 50 W of heat can be destroyed on the skin meter. Even though the dozhina is significant, it can become critical. I figured out what more stretch they will spend more. If it is necessary to pay the cost, then when increasing the cost to reduce the heat load on the radiator, add the cost to the pipelines, and then, for the total value, know the required diameter.

Determining the diameter of the pipes of the scorching system is not an easy task

Ale for individual scorching systems, the values are non-critical. It is more that with a rise in heat loss and tightness of the possession, most of the rounding of the rise in values is more pronounced in the case of an increase. Tse give a singing reserve, which allows not to work such foldable roses.

Important food: where are the tables? Mayzhe on all websites of the same tables. You can rent directly from the site, or you can download your own. But still, you didn’t know how to work, how much you need tables for the rozrahunka. You can use the system for choosing diameters described below, or you can work it out otherwise.

Irrespective of those that are required when marking different pipes different values(Internal abo zovnishni), you can equate them with a singing feat. According to the tables below, you can find out the type and marking with the given internal diameter. Here you will also be able to find the latest version of the trumpet from other material. For example, it is necessary to re-route the diameter of the metal-plastic pipes of singed. You didn't know the table for MP. Natomist є for polypropylene. Choose the dimensions for the PPR, and then, according to the tables, you know the analogues of the MP. Pohibka naturally, but for systems with primus circulation won't be allowed.

Table of validity different types pipes (press for expansion)

For this table, you can easily determine the internal diameters of the pipes of the scorching system and their marking.

Pidbir pipe diameter for scorching

This method of founding is not based on roses, but on regularity, which makes it easy to analyze a large number of scorching systems during an hour of analysis. This rule has been introduced by installers and vikoristovuetsya them on small systems for private houses and apartments.

The diameter of the pipes can simply be chosen according to the simple rule (click to increase the size)

From the larger scorched boilers, there are supply and return pipes of two sizes: ¾ and ½ inches. The axis of such a pipe and struggle to grow up to the first debridement, and then on the skin debridement, the rosemation changes by one crochet. In this way, you can determine the diameter of the scorched pipes near the apartment. The systems sound small - from three to eight radiators in the system, maximum - two or three wires, one or two radiators per skin. For such a system of proponing, the method is the main choice. Practically the same on the right and for small private houses. And the axis is even more than two on top of that larger system, then it should be done better and better with tables.

Podbags

With no more folding and opening systems, the diameter of the pipes of the scorching system can be opened independently. For whom do you need data about the heat loss of the application and the tightness of the skin radiator. Then, vikoristovuyuchi table, you can designate a cut of the pipe, as it runs into the supply of a lot of heat. Rozsіche folding rich-element schemes are best left to a professional. In the extreme mood, develop independently, but try to get at least a consultation.

The scorching system in a private booth can be primus stove or natural circulation. In the fallow type of the system, the method of rozrahunka of the diameter of the pipe and the selection of other parameters of scorching are different.

Articles on the topic:

Rozrahunok diameter pipes singed actual in the process of individual chi private life. In order to correctly designate the expansion of the system, the next thing to know: what are the mains (polymer, chavun, copper, steel), heat transfer characteristics, and how to move through the pipes. The introduction of the pressure pump into the design of the scorched richly improves the quality of the heat transfer and saves the heat. The natural turnover of heat in the system - classic method, which zastosovuetsya near most private booths on the steam (boiler) scorched. And in fact, and in another situation during reconstruction or new life, it is important to choose the right diameter of the pipes in order to prevent unacceptable moments in further operation.

The diameter of the pipe is the most important indicator, which measures the overall heat output of the system, which determines the foldability and the length of the pipeline, the number of radiators. Knowing the numerical value of this parameter, it is easy to develop and spend energy.

Pollution of KKD scorched according to the diameter of the pipelines

Povnotsіnna work of the energy system to deposit according to the criteria:

- The power of the ruhomoi rіdini (heat-bearing).

- Pipe material.

- Flow rate.

- Throughput pererіz chi pipe diameter.

- The presence of the pump in the scheme.

It’s never hard, the more you cut the trumpet, the more you will miss it. In times of increased enlightenment of the main line, we accept a lower pressure, like a legacy, a low flow of heat. Tse mozhe to bring to a new zupinky the turnover of the redine in the system and zero CCD. If you include a pump in the circuit, with a large diameter of the pipe and an increase in the pressure of the mains, the tension may be insufficient to ensure the required pressure. In case of interruptions in the electricity, the pump in the system is simply scorched - it will be scorched during the day, but do not heat the boiler.

For individual buildings from centralized scorching, the diameter of the pipes is chosen the same as for Russian apartments. At the booths steam scorched boiler type it is necessary to re-route the diameter. The length of the mains, the number of pipes, the number of inclusions in the water supply scheme of plumbing fixtures and radiators, the scorching scheme (one-, two-pipe) are covered. Table 1 shows the consumption of heat transfer in the fallow in terms of material and term for the operation of pipelines.

| Pipe | Vitrata m3/year | Speed m/s | Use head m/100m |

|---|---|---|---|

| Steel nova 133x5 | 60 | 1,4 | 3,6 |

| Steel nova 133x5 | 60 | 1,4 | 6,84 |

| PE 100 110x6, 6 (SDR 17) | 60 | 2,26 | 4,1 |

| PE 80 110x8, 1 (SDR 13.6) | 60 | 2,41 | 4,8 |

| Steel nova 245x6 | 400 | 2,6 | 4,3 |

| Steel is old 245x6 | 400 | 2,6 | 7,0 |

| PE 100 225x13, 4 (SDR 17) | 400 | 3,6 | 4,0 |

| PE 80 110x16.6 (SDR 13.6) | 400 | 3,85 | 4,8 |

| Steel nova 630x10 | 3000 | 2,85 | 1,33 |

| Steel is old 630x10 | 3000 | 2,85 | 1,98 |

| PE 100 560x33, 2 (SDR 17) | 3000 | 4,35 | 1,96 |

| PE 80 560x41.2 (SDR 13.6) | 3000 | 4,65 | 2,3 |

| Steel nova 820x12 | 4000 | 2,23 | 0,6 |

| Steel is old 820x10 | 4000 | 2,23 | 0,87 |

| PE 100 800x47, 4 (SDR 17) | 4000 | 2,85 | 0,59 |

| PE 80 800'58.8 (SDR 13.6) | 4000 | 3,0 | 0,69 |

Necessarily, a small diameter of the pipe will inevitably lead to a high pressure, which means an increase in the pressure on the good elements of the main line. Let's face it, the system will be noisy.

Diagram of the distribution of the scorching system

For the correct installation, support the pipeline, and then, the same diameter, follow the scheme of the distribution of the scorching system. Options:

- two-pipe vertical;

- two-pipe horizontal;

- single-pipe.

A two-pipe system with a vertical riser can be used with the upper and lower placement of the mains. One pipe system for the rahunok of the economical choice of the main pipeline for heating with natural circulation, the two-pipe for the rahunok of the hanging set of pipes is included in the pump circuit.

Horizontally split transmission 3 types:

- dead end;

- with a passing (parallel) drive;

- collector (or promeneva).

In the scheme of single-pipe distribution, it is possible to transfer a bypass pipe, as if it would be a backup main for the circulation of the radiator, with the inclusion of a few or all radiators. In the kit, on the skin radiator, locking taps are installed, which allow you to shut off the water supply, if necessary.

Knowing the scheme of the scorching system, one can easily determine the total length, one can obstruct the flow of heat in the main (at twists, turns, z'ednannya), and as a last resort, take into account the numerical value of the support of the system. For calculating the values of the cost, you can calculate the diameter of the scorching mains using the methodology discussed below.

Selectable pipes for Primus circulation system

The system of primus circulation of scorching is blown by the natural presence of the pump, which is pumped, which is mounted on a vent pipe not far from the boiler. The attachment functions as an electrical circuit 220 V. It automatically switches on (through a sensor) at the time of the movement of the pressure in the system (to be done when the radiator is heated). The pump quickly disperses hot water through the system, as it saves energy, and through the radiators it actively transfers it to the skin.

Searing with primus circulation - pluses and minuses

The main advantage of scorching with primus circulation is the efficient heat transfer of the system, which is achieved for the minimum amount of time and finance. This method does not mean the stowing of large-diameter pipes.

On the other hand, it is important for the pump in the scorching system to ensure uninterrupted life. Otherwise, scorching is simply not practical with a significant area of the booth.

How to calculate the diameter of the pipe for scorching with primus circulation according to the table

Repairing the rozrahunok from the designation of the occupied area of the premises, as it is necessary to heat in winter hour Tse all Zhitlova part of the booth. The standard for heat transfer of the opal system is 1 kW per 10 sq. m. (with walls with insulation and a height of stele up to 3 m). Tobto for accommodation with an area of 35 square meters. we set the norm to 3.5 kW. To secure a reserve of thermal energy, add 20%, which gives 4.2 kW. Behind table 2 we signify close meaning up to 4200 - ce pipes with a diameter of 10 mm (heat index 4471 W), 8 mm (heat index 4496 W), 12 mm (4598 W). For these numbers, the offensive value of the speed of the heat transfer flow (in the case of water) is characteristic: 0.7; 0.5; 1.1 m/s. Practical indications of a normal robotic treatment system are the speed of hot water from 0.4 to 0.7 m/s. Z urakhuvannyam tsієї mind zalishaєmo for the choice of pipes with a diameter of 10 and 12 mm. Vrakhovuchi vitratu water, economically zastosuvat pipe with a diameter of 10 mm. The variant itself will be included before the project.

It is important to distinguish between the diameters, with which the choice is made: external, internal, mental passage. As a rule, steel pipes pick up according to the inner diameter, polypropylene - according to the outside diameter. A beginner can get stuck with the problem of defining a diameter marked in inches - this nuance is relevant for steel mills. The conversion of inch size to metric is done through tables.

Rozrahunok pipe diameter for scorching with a pump

When pipes are scorched, the most important characteristics are:

- Quantity (volume) of water, which will be occupied by the heating system.

- Dovzhina of highways is steep.

- Flow rate at the system (ideal 0.4-0.7 m/s).

- Heat transfer of the system in kW.

- Pressure on the pump.

- Tick at the system when the pump is turned on (natural circulation).

- Opir system.

H = λ(L/D)(V2/2g),

de H - height, which means zero pressure (pressure head) of the water column for others, m;

λ – coefficient of pipe resistance;

L – dozhina (dovzhina) of the system;

D - internal diameter (shukana value in this direction), m;

V – flow rate, m/s;

g - constant, accelerated svіln. fall, g=9.81 m/s2.

Razrahunok is carried out minimally in the heat exhaustion, so that the value of the pipe diameter is changed to min opir. Flexibility to come out with a coefficient of hydraulic support - on the basis of the required tables for a long time, from the formulas of Blasius and Altshul, Konakov and Nikuradze. For the last values of the losses, a number less than approximately 20% of the pressure created by the pressure pump is taken into account.

When calculating the diameter of the pipes for scorching, L, it is assumed that the length of the main line from the boiler to the radiators is equal to the one at the gate, without fixing the rows, which are duplicated, placed in parallel.

The whole rozrahunok is built up to the point where it is necessary to equalize the value of the support with the pressure pumped by the pump with the help of the rozrahunkov path. If you happen to happen, it’s possible, more than once, to figure out the formula, vicarious different values of the inner diameter. Start with trumpets with a 1 inch strand.

Forgiveness of the rozrahunok of the diameter of the trumpet of scorching

For a system with primus circulation, there is one more formula:

D = √354 (0.86 Q/∆dt)/V,

de D - Whispering inner diameter, m;

V – flow rate, m/s;

∆dt - water temperature difference at the inlet and outlet;

Q - Energy, which is emitted by the system, kW.

There is a temperature difference for a vicorist, which is about 20 degrees. So, at the entrance to the system from the boiler, the temperature is close to 90 degrees, when moving through the system, the heat input becomes 20-25 degrees. And at the gate, the water will be colder (65-70 degrees).

Razrahunok parameters in the scorching system from natural circulation

Razrahunok pipe diameter for a system without a foundation pump on the difference in temperature and pressure of heat transfer at the inlet to the boiler and at the return main. It is important to guard that the motherland is collapsing with pipes for the help of the natural force of gravity, strengthened by the pressure of heated water. In this case, the boiler is placed at the bottom, and the radiators are richer for the heating fittings. The movement of heat transfer follows the laws of physics: a lot of cold water goes down, acting as a hot mass. This is how the natural circulation of the scorching system is established.

How to choose the diameter of the pipeline for scorching with natural circulation

On the vіdmіnu vіd vіd systems іz primusovoi tsirkulієyu, for the natural turnover of the water will be required dimensional cut pipes. The greater the flow of circulation through the pipes, the greater the heat energy in the room at one hour due to the increase in speed and the pressure of heat transfer. From the other side, move the water in the system more vimagatim more fire for the rose.

Therefore, in private booths with natural circulation, the first task is to develop the optimal scorching scheme, for which the minimum length of the circuit and the distance from the boiler to the radiators are selected. To that, in the houses with a great living area, it is recommended to install a pump.

Yulia Petrichenko, expert

For a system with natural heat transfer, the optimal value of the flow rate is 0.4-0.6 m/s. To whom the contractor is given the min value of the supports of the fittings, bending of the pipeline.

Razrahunok vice in a system with natural circulation

The difference between the pressure between the entry point and the one wrapped for the natural circulation system is determined by the formula:

Δpt= h g (ρot – ρpt),

de h - Height of the water column from the boiler, m;

g - accelerated fall, g = 9.81 m/s2;

ρot - the amount of water at the turn;

ρpt - width of the pipe in the pipe, what is supplied.

So, as the main driving force in the system of scorching with natural circulation is the force of gravity, created by the difference in the water supply to the radiator and in the air, it is obvious that the boiler will be significantly lower (for example, at the foot of the house).

It is necessary to shave off the boiler from the entry point of the boiler to the end of the row of radiators. Uhil - not less than 0.5 ppm (or 1 cm per running meter of the main line).

Roofing of the pipe diameter in the system with natural turnover

The diameter of the pipeline in the heating system with natural circulation follows the same formula, which for scorching with a pump. The diameter is selected on the basis of subtracting the minimum costs. In order to change the formula to add one value to the review, it is re-verified on the basis of the system. Let's see a friend, a third of the distance is significant. So doti, as long as the diameter of the insurance is nothing to please the minds.

And how do you pick up the relining of the main? What method of rozrahunka will you zastosovuєte? Share, be kind, in the comments.

Expertise - koshtorisnik engineer

Ask an expert

Pipe diameter for scorching with primus circulation, with natural circulation Version for a friend