Systems of scorching from pump circulation. Water-filled scorching system

The water scorching system is one of the widest. To whom do you sprinkle a sprat of factors:

- Universality of heat sources (electricity, gas, wood, firewood);

- Rivnomirne warming up the place;

- Bezpeka;

- Chi does not flow into the warehouse again in the premises.

Principles of work

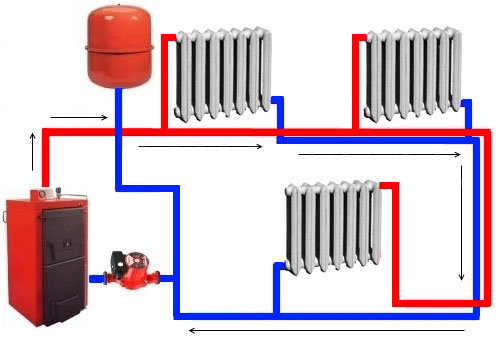

The essence of the robotic be-like system of water scorching of the offensive. The heat carrier is heated in the boilers, then the system of pipes expands along the premises, decools in the radiators, giving heat to the premises, and turns into the boiler for the onset cycle. Cauldrons at tsomu can be but be-yakim or їх іх іліy complex. Water is the most common source of heat, as well as antifreeze and special heat transfer. When different special heat transfers are used, the term of system operation is increased, the possibility of defrost is switched off.

According to the type of heat transfer circulation, they distinguish:

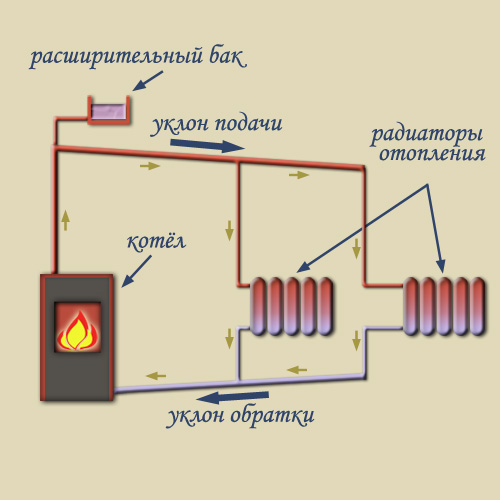

W natural circulation . Heating heat-carrying may be a greater pressure lower cold. Zavdyaki ryznitsі vise vіdbuvaєtsya circulation. For such a system, it is necessary to lower the yakomoga boiler lower. The lower the boiler, the greater the vice (located in the basement). The inner diameter of the circulation pipes is to blame but not less than 32. The pipes of the guilty mother died (not less than 1 cm per skin meter of the main) from the entry point to the rest of the radiator. Otherwise, just above the boiler at the top point of the entire system, expand the expansion tank and vibrate the expansion. It is not recommended to plan a system with natural circulation behind a long circuit more than 30 meters;

With primus circulation. The installation system has a circulation pump. In this case, not laying an important diameter of pipes, rozashuvannya boiler and different things died. With a hole in the diameters of the pipes, the increase in circulation can increase the pressure of the pump.

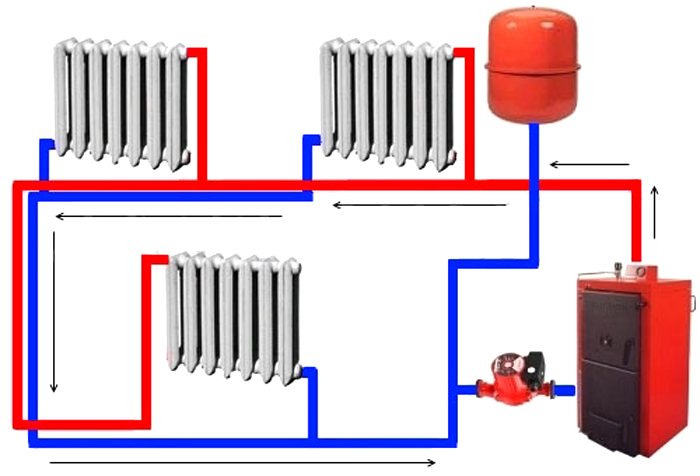

By pipe distribution:

- One-pipe. In fact, the scorching radiators are connected to the ring pipe, or the scorching circuit goes through the radiators;

- Double pipes. Two cycles are carried out on the premises: a separate supply and return. Radiators of scorching are connected to both.

For tightness:

- Vіdkritі systems. It is installed vіdkritiy expansion tank;

- Closed systems. There is no contact from the familiar atmosphere.

Behind the contours:

- Single circuit;

- Rich contours. Stop at great squares and it is necessary to adjust the temperature in different pharynxes.

Planning a water scorching system

1. Choose mind. For small applications, systems of scorching from natural circulation can be used. The capacity of the pump will require the accuracy of the implementation and the larger diameter of the pipes. Gnuchkish circulation systems in management. Well, there are two-pipe and rich-contour ones. Open-ended and closed-type retail is unprincipled. For different types, you need to place a expansion tank at the top point of the system;

2. Heat sinks. Merezha has impersonal "wise" rozrahunkivs and a lot of radiators. It is proponuєmo vikoristovuvati rational. The heated area of the surface of the radiators is scorched - 10% of the area of application to be scorched (with standard characteristics of the application: the height of the beds, the norms of insulation, etc.). Tsya norm not to fall due to the declared tightness of radiators, heat losses and others. Such a heating itself allows you to carry out even heating of the application, and the tightness is rich in what is set by the temperature of the heat transfer. Vikoristovuvati radiatori can be-yakі. With non-centralized scorched, there will be no real retail. In central heating systems chavunnі radiators may have an insignificant advantage (before they save heat and vitrimuyut a greater pressure on the process of trivalo exploitation). Plan the installation of radiators rather than yakomog rozpodіleni for the area of application. For equal heating, the most optimal system of pipes is the replacement of radiators, but it is not aesthetically pleasing;

4. Circulation pipes. For systems with natural circulation, it is necessary to vicorize metal pipes - the stench does not deform under the influx of heat, after which it does not blame the additional support. The diameter is not less than 32 mm, the smaller the outer circuit of the system, the larger the diameter of the pipes. For systems with primus circulation, the diameter of the pipes is less important, but the diameter of the main pipes is not less than 25 mm. A small overcut (20, 16 mm) is allowed to enter the scorched radiators. Better prepare a scorching system polypropylene pipes: low cost, ease of installation and repair;

5. Collections. When choosing the implementation of a system based on polypropylene pipes, the inlet and outlet collectors are welded independently from pipes of a larger diameter and galvanized pipes, control valves are installed on the contour pipes. Collections are allowed to include different sizes Opal system that carry out repairs on them without teeth of the entire system as a whole;

6. Security systems. When the system is closed, the installation of outside valves, the installation of accessories: vimiruvach and temperature on the pipe, what is supplied, and temperature on the gate;

7. Circulation pump. The choice of the pump is to be deposited according to the parameters. Nasampered - to the height of the pidyom. However, with a large support (rich contours, insufficient pipe diameter), the tightness of the pump can be insufficient for a single-surface scorching system. Coarse spray: on the skin of 10 meters of the circulation ring - 0.6 meters of pump pressure, wipes on the skin of 100 square meters - 0.5 cubic meters of pump productivity.

Installation of the heating system

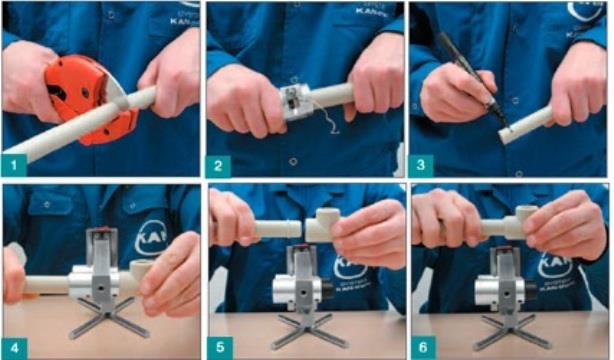

Polypropylene pipes, richly contoured, closed two-pipe system are taken as a basis.

For installation you need:

- standard set of tools: twist, pliers, hammer, tape measure and more;

- soldering iron for polypropylene pipes;

- trumpet lower.

- Situationally - perforator, drill and other.

From materials:

- pipes, fittings, taps;

- scorching radiators, plugs, adapters, grass taps, temperature regulators for the radiator;

- circulation pump; main filter;

- safety systems (outlet valve, temperature control), valves for automatic air descent;

- expansion tank.

Installation of radiators

We install radiators of the scorching system on the plate. Radiators are connected like this. At the lower part, out at the back, from the other side, the lower part is muffled. Vgorі - from one side of the entrance from the pipe, what is given, from the other crane of May to bleed the air.

For the shortest temperature regulation, it is recommended to install a tap without difference on the supply or return of the skin radiator. The installation of two taps does not cause any special sensation, when the radiator goes out of the way of the heat-carriers, without any special difficulties, it swells from the left circuit. The tap can be tapped with automatic temperature control.

On the first radiators, the circuit is recommended to install a grass tap replacement - a valve for automatic descent of the wind. As practice has shown, the first hour of the work of the scorching system, the first radiators are often required in the process of operation.

For the implementation of a scorching system based on polypropylene pipes, it is not recommended to install radiators with “American” circulation pipes. For an hour, the picture is sprouted for an hour: the Gumov Kilza Nakolnyuvach is rude, in the fallen season, the gagge-roding gum human-roding gum in the Olekholodeni (ceasing to the pickwell of the cauldron of the reasons) is the tightness of the zeritanny, in the result, the result is warmly used.

Installation of circulation pipes

Zvichayny installation and installation of polypropylene pipes. Blow bazhano vikoristovuvati for hot water with reinforcement, the stench is less strong to thermal expansion. It is also not recommended to beat the pipes from the old reinforcements - additional clots from stripping before soldering.

Installation of collectors

Inlet and outlet collectors are soldered from polypropylene pipes, tees, crosses, taps. A tap is installed on the skin to the contour. Tse allows you to use the temperature curve and give you the ability to work with an okremiy contour without a tooth of the entire scorching system. You can come with a ready-made collector.

Collector є rozgaluzhuvachem. Inlet - from one pipe, what is supplied, from the boiler in different circuits. Outlet - from different circuits into one wrapper pipe, which is straight into the boiler.

Installation of expansion tank

The expansion tank at the closed system can be installed in any place. It is recommended to install and connect the tank directly in front of the entrance to the boiler or to the pump. It is necessary to install a bypass valve at the expansion tank inlet. It is not allowed to install taps between the tank and the system.

Group security installation

The safety group can be placed at different places (on the boiler, at the expansion tank, in front of the collector). To enter the safety group: an outside valve with a raised vice, a valve for automatic descent of the air, and also can be supplemented with vimiruvacs and temperature.

Wimogi to group safety:

Guilty to roztashovuvatsya immediately after leaving the boiler without knowing between her and that boiler, be it any outbuildings;

It is not allowed to install a tap between the safety group and the boiler outlet.

Installation of the circulation pump

The circulation pump is installed immediately before entering the boiler. A main supply filter is installed in front of the circulation pump - to prevent particles of fire, scale and another great smite from getting into the pump and the cauldron. The circulation pump is mounted strictly according to the instructions to the new one (vertically, horizontally, straight down).

When installing in the system two vimiruvachіv temperatures (at the inlet and at the gate) it is possible to judge the adequacy of the pressure of the pump. Even though periodically the difference between temperatures reaches 20 - 30 ºС and more - you can talk about the lack of tightness of the pump, especially if you have to change the wrap around the boiler, or the automatic boiler will automatically heat up.

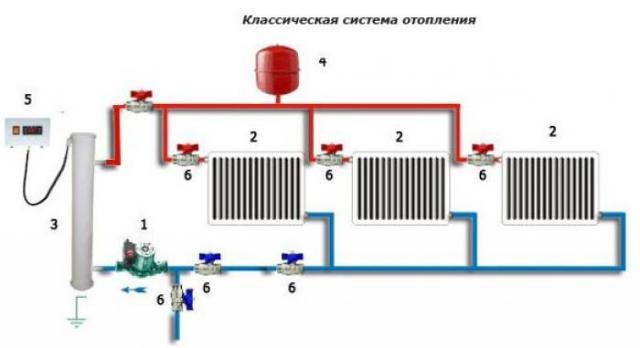

Povna scorching scheme

For rozuminnya, we induce a new scheme of scorching, starting from the cauldron.

The heat-carrier is heated near Kazan. Let's go to the system. To the point without taps, a security system is connected. Up to the center point, the inlet pipe of the inlet collector is connected. At the collector, there is a distribution of heat transfer behind the contours, the windscreen is regulated by the same taps.

The supply pipe in the circuit will pass through the air of the remaining radiators and will end with the entrance to the remaining circuit. Through the heat exchanger, the heat exchanger is drained from the return pipe to the circuit. Protilezhnist also pass vdovzh usіh radiators, starting from the extreme and ending with the entrance to the external collector through the crane. The leather radiator can be equipped with a faucet at the exit or at the entrance.

The heat-carrying fluid is collected from the dry circuits at the outlet collector and is fed to the tailpipe. Through the return pipe, the cold heat-carrying fluid passes through the main filter, and goes into the circulation pump. Up to the point of connection without taps expansion tank. It is permissible to expand the tank and connect it to the exit from the cauldron. The pump creates a vice and stocks of heat transfer at the boiler inlet.

Scheme of a two-pipe system of water burning

Everything on your own is obvious, as with skin rock, prices grow on the palm. І obіtsyanki, that everything will be kind in no time, they no longer marvel at us, but show life in a different way. So sho poryatunok stomping - to the right of the hands of the stomping themselves. To that, if there is food about scorching wet booth, next podbat about the correct solution. Tse pov'yazano i z, і z pіdboro opalyuvalnogo boiler.

If it’s easy to finish everything with a boiler, then it’s possible to improve on the schemes, even if few people from the vlasniks of the vlasnyh houses professionally understand them. A lot of schemes for singing vidov budinkov simply do not fit. Otzhe, you can have mercy, so do not take to respect the recommendations of fahivtsiv.

Why start?

We will indicate the pressure of the boiler. What to lie down? Nasampered, in view of the volume of the booth - less volume, then less tightness, a boiler is needed. However, here it is important to remember the deeds of the heating of the choice of the boiler room.

For example, energy efficiency. In zamіsk settlements and small towns, parts of the electricity supply are connected. Really gas boilers- the most energy-storing units, the design of some of them has a circulating pump. If the pump is not working, then the efficiency of the boiler drops sharply. And to state that the scheme of distribution of your scorching is not good enough to undermine the pressure of the middle pipelines. Come out, it's not suitable for your donkey.

Let's take a look at the butt, which clearly illustrates how the real boiler falls out of the heating system, as if the circulation pump stops working.

We choose the scheme of distribution

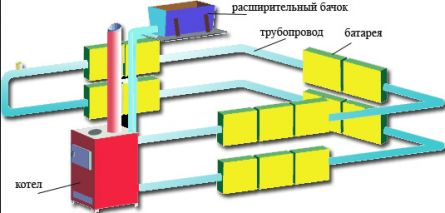

Take, for example, the scheme, as the people call "Leningradka". It's simple, cheap, and at the same time effective. The first її element is the whole boiler, installed at the lowest place. If I went to the booth, then I’ll tell the cauldron myself there. And if you don’t know anything, then you have to prepare a pit, and concrete the bottom of the walls. The axle is there and it is necessary to install a scorching unit.

The other component is the pipeline, or rather, the piping. Z'ednannya main highway, like in other schemes - in the form of a cauldron on the whole booth again until the cauldron. Ale, there is one nuance, which is the characteristic rice of "Leningradka". Opaluvalni radiators install along the entire main line, and bring the supply and return lines to it. Opaluvalny battery output and input come to one trumpet. Leningradka has no undercurrents, no undercurrents. One pipe and one main line. At tsomu її simplicity that vіdmіnna rice.

The heat-carrying one collapses on the stake, often filling the radiators. Part of the hot water is penetrated into the batteries, and part of it is far away. At what temperature remain at the lancer scorching accessories you will be lower, lower, quiet, who will stand in front. Also, in the rest of the rooms, it will be colder, lower in the first ones.

Connecting pipes to radiators

What work? There are two exits:

- Increase the number of sections of radiators in the remaining rooms, thereby increasing the heat supply.

- Install circulation pump. Alece energy saving method.

And yet not all. This type of pipe distribution can be used, as your booths may have a sprinkling on top. At this point, a one-pipe scheme with an upper branch is installed. A pipe is connected to the skin radiator with the supply of hot water and a return pipe is introduced. Ale on the skin surface in the skin room one under one battery installed, connected by one risers (supply and return).

Go out to finish simple circuit, where the upper radiators take more heat, and, apparently, the stench is hot, and the lower ones are less, so the stench is cold. The larger the surfaces, the less the heating temperature on the lower surfaces. Whom has a minus of this system.

Chi є out? You can rebuild the radiator sections on the lower surfaces or install a circulation pump.

Two-pipe scheme

Everything that was described above, is brought before single pipe systems scorching of private houses. In the present hour, vicorists are not so often, like 50 years ago. The most popular today are koristuyutsya, among them are obvious leaders.

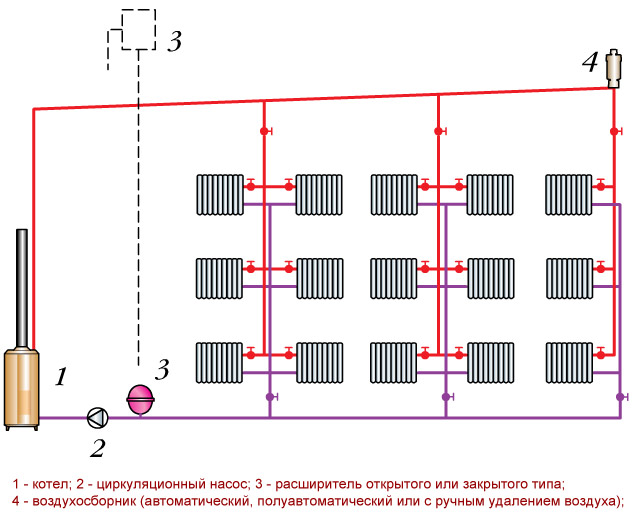

Butt - collector or exchange system. In order to escape the pressure of heat transfer and temperature differences in all scorching accessories, it is necessary to make sure that the skin heat sink has the same amount of heat transfer with the same temperature. Later, the okrema magistral vіd boiler can reach the skin opaluval attachment. But let me tell you, it is necessary to install several pipes in one heating unit! Such vipadkas vikoristovuєtsya collector system rozvyazki.

The widest system

What is it? Collector - tse vuzol, in which z'єdnаnі riser, scho to lead, to the boiler and to bring pipelines to the radiators. That is why the equal distribution of heat transfer at the points, where the heat is released into the skin room is OKremo. Tse best scheme of burning.

Often fakhіvtsі gladly install two collectors - one for the animal to supply heat, and the other from the bottom for the collection of hot water, which is on the return line.

But still, it’s richly stale in the factor, yakі іnоdі vrahuvati smoothly. For example, yak windows are installed in this chi іnshіy kіmnatі, yak close to the entrance doors the room is installed, like the surface of the budіvl, chi є thermal insulation and more. That is why it is possible to regulate the flow of heat transfer by mains, and, apparently, the temperature in the middle of the place, to install locking valves on the collectors. With help, you can easily change or increase the supply of hot water to the scorching accessories.

If it became colder in one of the rooms, then on the collector it is necessary to increase the supply of heat to the same room, by opening the valve more. Ring out manually.

Visnovok on the topic

To look at all the schemes of scorching systems, it is necessary to select a wide range of nuances when choosing. Basically, the dimensions of the booth, the pressure of the boiler and the presence of the circulation pump. Truth is, what a constant remaining criterion plays a leading role. In most cases, the primus circulation of heat transfer is stagnant in all types of private houses, even with an eye to the possibility of transferring the system to natural circulation.

How about your locality often turn on electricity, it is necessary to turn on the bypass, in the system of any and installation of the pump. As the electricity flickers, the main line turns straight, and the bypass closes. Tobto opalyuvalna system begins to work in the natural regime. Axis to you and exit from the camp.

As has already been repeatedly guessed, the head shortfall of the scorching system with natural circulation of heat transfer is a low circulation pressure (especially in the apartment system) and due to the large increase in the diameter of the pipes. To finish a little bit of mercy with a choice of pipe diameters and heat-carrying ones, even “jamming” and you can’t fix a hydraulic support. It is possible to “expand” the system without any significant reworks: turn on the circulation pump before it (Fig. 12) and transfer the expansion tank from the feed to the wrap. The next step is to indicate that the transfer of the extension to the wrapped does not have to be obov'yazkove. With a simple reworking of an awkward opal system, for example, an apartment system, the tank can be left there, standing upright. With the correct reconstruction or the installation of a new system, the tank will be transferred to closed and replaced from closed to closed.

Rice. 12. Circulation pump

What tightness can be a circulation pump, how and where should I install it?

Circulation pumps for piping systems of scorching may have a low reduction in electricity - close to 60-100 W, so like a great light bulb, the stench does not raise water, but rather help to hem the support in the pipes. The pumps can be coupled with the ship's rudder (gwent): the gwent shoves the water and ensures the safe passage of the ship, but when the water in the ocean does not change and is not added, then the deep balance of the water is left by ourselves. Circulation pump, fastening to the pipeline, supplying water, but the scallops are not screwed in, from the lower side to the new one, there is also a small amount of water, so that the pump is not heat-carrying through the expansion valve: the system is scorched, the brush is a closed circuit at new postiyne. The circulation pumps in the centralized system can be turned on, pumping, pumping water and pumping water, it’s important to call them pumps, and the circulation pumps, at the crossroads, it’s important to call them pumps ... it’s important ... fans. Skilki would not have blown the main butt fan around the apartment, everything is on the building’s fault, create wind (recirculation), but not the building’s atmospheric pressure to wind the closed room.

As a result of the stasis of the circulation pump, the radius of the opalizing system significantly increases, the diameter of the pipelines shortens, and the possibility of connecting the systems to the boilers is created due to the change in the parameters of heat transfer. In order to ensure the noiseless operation of the scorching water system with pump circulation, it is not the fault of the circulation of heat transfer: for pipelines that are laid in the main areas of residential buildings, with mental pipe passages of 10, 15 and 20 mm, and more than 1.5; 1.2 and 1 m/s; at pipelines that are laid at additional premises of living quarters - 1.5 m / s; for pipelines that are laid near additional buildings - 2 m / s.

To ensure the noiselessness of the system and the delivery of the necessary heat transfer obligation, it is necessary to build a small rosary. We already know how to orientate the necessary pressure of the boiler (in kilowatts), moving out of the area of application, which are scorched. The optimal amount of water flow to pass through the boiler, recommendations made by boiler companies, are protected by a simple empirical formula: Q \u003d P, de Q - heat transfer rate through the boiler, l / hv; Р – boiler pressure, kW. For example, for a boiler with a heat output of 30 kW, the volume of water should be approximately 30 l/h. To determine the heat exchange rate on the circulation circle, we can use the formula, knowing the tightness of the radiators, which are installed on this gap, for example, we conduct a winding up of the water for radiators installed in one room. Let's assume that the intensity of the radiators becomes 6 kW, and the heat transfer rate becomes approximately 6 l / hv.

Behind the winding water, the diameter of the pipelines is determined (Table 1). The values of the values are accepted in practice as the diameter of the pipes with a high heat transfer rate, which flows through them, with a speed of no more than 1.5 meters per second.

Table 1

Dalі vyznaєmo the pressure of the circulation pump. On the skin 10 meters long of the circulation ring, 0.6 meters of pump head are required. For example, for example, the headroom of the pipeline pipe is 90 meters, for example, the pump can be 5.4 meters. Let's go to the store (or choose from the catalog) and buy a pump with pressure, which is our power. As a rule, pipes of smaller diameters should be installed, as recommended below in the previous paragraph, the pressure of the pump is to blame, but the pipes are thinner, and they have a larger hydraulic opir. I, apparently, when pipes of large diameters are blocked, the pressure of the pump may be changed.

To ensure constant circulation of water in the scorching systems, it is necessary to install at least two circulation pumps, one of which is working, the other (on the bypass) is reserve. Otherwise, one pump is installed on the system, and the other one should lie in a quiet place, at the same time replace it if the first one breaks down.

It is necessary to note that the indications here for the development of the scorching system are even more primitive and not harmful factors and features of the individual scorching system. If you are going to have a cottage with a folding architecture of the scorched system, it is necessary to work accurately. Tse can only work less heating engineers. It is not at all sensible to make a rich multimillion case without any documentation - a project that protects all the features of everyday life.

Circulation pump in the opaluvalny system of filling with water and venting (so the water is not heated) hydrostatic pressure on two sides - on the side of the inlet (switching) and outlet (injection) pipes, connected with heat pipes. Such circulation pumps, crushed with water oil on bearings, can be placed both on the supply and on the return pipeline, and most often they can be placed on the gates. On the back of the head, it was suggested by a daily technical reason: when placed in cold water, the term for the service of bearings, rotor and stuffing box was changed, the pump shaft must pass through the yak. And at the same time, put it on the wrapped shutter behind the star, so from the point of view of the creation of piece circulation of water in a closed circuit, the space of the circulation pump can be stoked. If you want to place them on pipelines, what you supply, de sound less hydrostatic pressure, more rationally. For example, the expanding tank of installations at your system at a height of 10 m from the boiler, which means that it creates a static pressure of 10 m of water column, but the hardening is more correct only for the lower pipeline, at the upper vice it will be less, so it will be smaller here. If you don’t loosen the pump, you will be under the same pressure on both sides, put it on a vertical head feeder or a swivel riser, the difference between the pressure between the two pump nozzles will be small, so the pumps may have small dimensions.

Ale, it's not that simple. The pump, which runs in a closed circuit of the scorching system, enhances circulation, pumping water into the heat generator from one side and closing it from the other side. The water rivulet in the expansion tank does not change when the circulation pump is started; Oskіlki for tsih minds (equanimity of the pump and the volume of water in the system) the riven of the water in the expansion tank is taken permanently, baiduzhe, the pump is working, the hydrostatic pressure at the point of expansion to the pipes of the system will be constant. This point is called neutral, because the circulation vice, which is developed by the pump, does not flow into the static vice created by the expansion tank. In other words, the pressure of the circulation pump in this point is equal to zero.

In case of a closed hydraulic system, the circulation pump has a vicorist expansion tank, like a point in the vіdlіku, in a vise, which is developed by the pump, changing its sign: to the ciєї point the pump, creating compression, pumping water The heat conduits of the system from the pump to the point of constant pressure (in respect of the direct flow of the water) will be carried to the discharge zone of the pump. All heat conductors after the first point - up to the soaking zone. In other words, if the circulation pump is inserted into the pipe line immediately after the point of entry of the expansion tank, then we will pump water from the tank and inject it into the system, if we install the pump in front of the point of entry of the tank, then the pump will inject water into the system

Well, well, as we are different, the pump pumps water from the tank, or pumps it into the new one, abi vin twisting it behind the system. And the difference is the same: a static vice is introduced into the robot of the system, with a expansion tank. At the pipelines, roztashovanih near the pumping zone of the pump, they should be connected to the movement of the hydrostatic vice in the pipeline with the pressure of the water in the calm state. Navpaki, in pipelines roztashovannyh near the zone of pumping of the pump, it is necessary to repair the reduction of the pressure, at its own possibility, if the hydrostatic pressure drops to atmospheric, and you can viniknuti razrіdzhennya. Tobto, in the aftermath of the pressure on the system, there is a problem with the introduction of water, or the winding up, or the boiling of the heat.

In order to avoid disruption of the circulation of water through її boiling or podsmoktuvannya again during the design of the hydraulic heating systems of water scorching, the rule can be trimmed: at the zone of smoking, at any point in the pipeline system, the hydrostatic pressure is superfluous due to the pressure of the pump. Possible ways to follow this rule (Fig. 13).

Rice. thirteen. Principal schemes scorching systems with pumped circulation and ventilated expansion tank

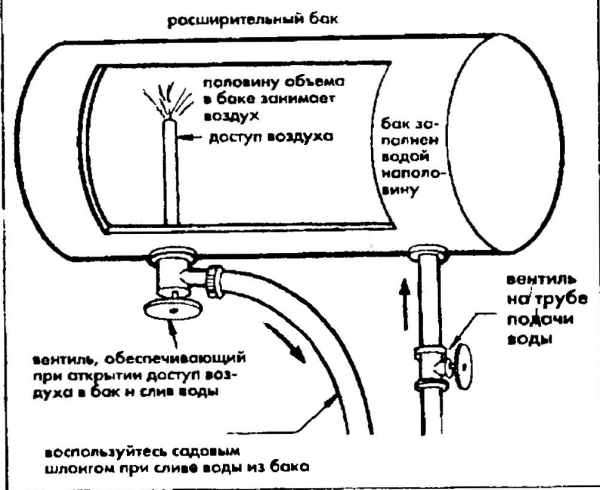

1. Raise the expansion tank to a sufficient height (sound no less than 80 cm). It is necessary to achieve a simple method in the reconstruction of systems with natural circulation into pump circulation, in addition to the significance of the height mountain dwelling that is the outer insulation of the expansion tank.

2. Relocation of the expansion tank to the safest upper point with the method of switching on the upper main to the discharge zone. Here it is necessary to add some explanation. In new scorching systems, the pipelines that are supplied, with pumping circulation, sway with shackles not in front of the boiler, but to the boiler, in order to repeat the bulbs collapsed along the way with water, the shards of the spontaneous force of the circulation pump will not allow them to whistle "against the leak", as it was in systems with natural circulation. Therefore, the upper point of the system does not go to the head riser, but to the largest in the distance. For the reconstruction of the old system with natural circulation, the pumping method is laborious, which means rebuilding pipelines, and for the construction of a new system, it is not true, because there are more options in the distance.

3. Connecting the pipes of the expansion tank near the suction pipe of the circulation pump. In other words, if we are reconstructing an old system with natural circulation, then we simply mount the tank in the main, which is supplied, and interlock it on the gate behind the circulation pump and we create the most for the pump smart mind.

4. Vіdhodimo vіd vіd zvіchnії scheme pоmіshchennya pump na zvorotі and yоgo yogo v іstralі, scho podєі, іn_drazu priіdnannya priіdnannya rasshiruval'nogo cistern. When reconstructing a system from natural circulation, the simplest way is to simply install the pump at the supply pipe, do not remake anything else. However, prior to choosing a pump, it is necessary to put it even more respectfully, nevertheless, it is reasonable to place it at unfriendly minds and high temperatures. The pump is responsible for its long and reliable service, but it can only guarantee solid virobnik companies.

The current market for plumbing and opal fittings allows you to replace expansion tanks of the open type in the closed. At a closed tank, there is no closure of the system’s core, as it turns out: the heat-carrier does not evaporate and becomes sour. It reduces the waste of heat and water, changing the internal corrosion of scorch fittings. From the closed cistern, the country never sees its names.

Expansion tank of a closed type (“expansomat”) - a capsule of a kulya or oval shape, divided in the middle by a sealed membrane into two parts: I will repeat the core. At the part of the hull, under a singing vice, a nitrogen mist is pumped. Before filling the opalizing system with water, the pressure of the gas bag in the middle of the tank strongly presses the diaphragm to the water part of the tank. Heat up the water until the working pressure is closed and the volume of heat transfer is increased - the membrane opens at the side of the gas part of the tank. With the maximum working pressure and the maximum volume reduction, the filling of the water part of the tank and the maximum compression of the gas sum are carried out. If the pressure continues to move and continues to increase the volume of heat transfer, then the right valve is used, which throws off water (small 14).

Rice. 14. Membrane expansion tank

The volume of the tank is selected so that the first cor- rision volume is not less than the volume of the thermal expansion of the heat transfer, and the front pressure is reversed in the gas part of the tank to be equal to the static pressure of the heat transfer in the system. Such a grip of the gas mixture allows the membrane to be trimmed in an equally important (not stretched) position when filling, but not turning on the scorching system.

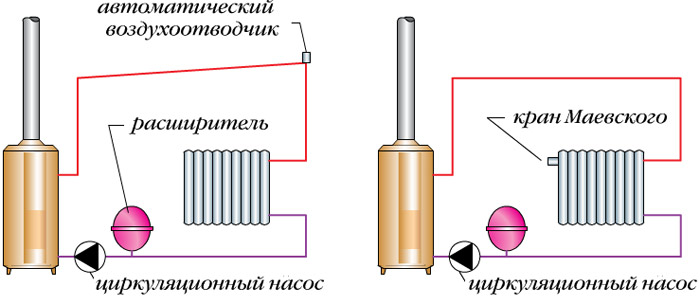

A closed-type tank can be placed in any point of the system, but, as a rule, it is necessary to put it in order with the boiler, but the temperature in the place where the expansion tank is installed is due to the minimum temperature. And we already know that the circulation pump is best installed behind the expander, where for the new one (the one for the scorching system as a whole) the most friendly minds are created (Fig. 15).

Rice. 15. Principal diagrams of scorching systems with pump circulation and expansion tank of closed type

However, for such a scheme of the scorching system, there are two problems: remote control and movement of the vise on the boilers.

Although in systems with ventilated expansion tanks, it was seen again and again through expansion leaks (in systems with natural circulation) or incidentally (in systems with pumped circulation), then this is not seen from closed tanks. The system is completely closed and the names just don't work. For removal of broken plugs at the top point of the pipeline, automatic drains are installed again - accessories, secured with floats and shut-off valves. In the world of increased pressure, the valve spratsovuє and bleed air into the atmosphere. Abo leather radiator singed installed faucet Mayevsky. This part, installed on the scorching attachment, allows you to release the jam without interruption from the radiators. Mayevsky’s crane is included in the set of some models of radiators, but in most cases it is recommended to be okremo.

Rice. 16. Automatic turn signal

The principle of dії vіdvіdnіkіv poіtrya (small. 16) is based on the fact that when there is a repeat, the float should be used in the middle of the fitting, the exhaust valve will be closed. If you climb again in the float chamber, the water in the middle of the windshield will decrease. The float is lowered and the exhaust valve opens, through which it is released into the atmosphere. As soon as the exit is repeated, the rhubarb is driven into the water pipe again, and the float of the drain is moved to close the intake valve. The process is trivaє doti, until you again get out in the chamber of the float and do not lower the water level, lowering the float. Automatic air vents are made in different designs, shapes and sizes and can be installed both on the main pipeline and without center (L-shaped) on radiators.

Mayevsky's crane, on the view of the automatic winder, the main plug with the winder channel and screwed into the new conical screw: the wyvertan of the screw turns the channel and repeats the name. The throaty gwent closes the channel. Also, there are guards, in which the replacement of the cone screw is replaced by a metal bag, which cuts off the channel of the air evacuation.

Instead of automatic air vents and Mayevsky taps, a heat separator can be included in the scorching system. This attachment is based on the stosuvanni law of Henry. It seems that in the systems of scorching, it is often found in the sight of a wide variety, and often in the sight of microbulbs. When passing water (at once from repeat) through the system, it will be consumed in the region of low temperatures and pressure. Vidpovidno to the law of Henry in some areas, it is more likely to be seen in water, and in others it is different. At the heat-carrying boiler it is heated to a high temperature, so in the future, in order to take revenge again, the greatest number of repetitions will be seen at the sight of dry bulbs. If you don’t see them nega- tively , then the stench will be different in other parts of the system, where the temperature is less. As soon as you see micropuffs in the drain behind the boiler, then at the outlet of the separator we take away water, as if it were clayed in other parts of the system. This effect is victorious for the cooling of the wind in the system and the introduction of yoga into the atmosphere for the additional combination of the boiler and the wind separator. The process is three-by-one until the re-excretion from the system.

Rice. 17. Perspiration separator

The robot separator repeat (Fig. 17) is based on the principle of microbulb agglomeration. Practically, it means that small bulbs repeatedly stick to the surface of special rings and are picked up at once, fixing large bulbs, so that they can hydrate and splive at the surface of the separator chamber. If the sweat of the motherland passes through the rings, the veins separate in the faceless different directions, and the design of the ring is such that the whole motherland can pass through them, coming into contact with their surface, the robbing can stick to the microbulbs and their anger.

Rice. 18. Principal diagrams of scorching systems with pump circulation, expansion tank of closed type and air separator

Now the three of them are moving out again and turning back to the circulation pump. In scorching systems with long pipelines and, as a result, with great hydraulic losses, it is often necessary to pressurize the circulation pumps, which create a vice on the branch pipe, which pumps, moreover, on the pit of the scorching boiler. That is, when the pump is placed on the return side, without being in the middle in front of the boiler, air can flow into the boiler heat exchanger. In order to prevent this from happening, the hard circulation pumps are installed not in front of the boiler, but behind it - on the pipeline that is supplied. And immediately post nutrition: de-roam the separator again, after the pump, what is in front of it? Conductors of scorching systems broke the supply chain and tried to install a separator in front of the pump (small 18) in order to protect it with bulbs again.

And now let's take a look at the scorching system with pump circulation report.

| back |

The skin should be applied independently, depending on the intended purpose, it will require scorching. As before, the main method of scorching the houses was adopted to use the stone or scorching method, then at the same time it became the least effective and demanded: it was not built to give enough heat through the scalding objects. One of the most advanced options for scorching is taken into account scorching water. The standard water scorching system includes a boiler connected from a radiator for auxiliary mains. Like heat-carrying water stagnates.

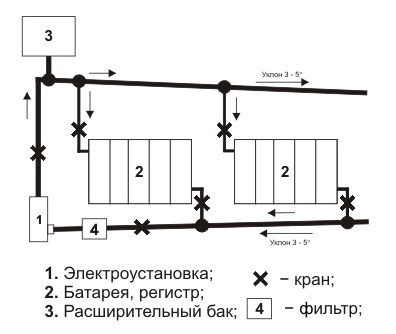

The standard principle of the robotic system works in the offensive: heat-carrying, there is water in this direction, go through the pipeline at the radiator and bring in heat; after which the water is turned to the cauldron for heating again. Water scorching systems are subdivided into systems with natural circulation and with primus circulation.

The system of scorching with natural circulation nabula was wide and wider in the pre-war period for the sake of its efficiency, simplicity and reliability. Most often, this type of scorch system is found in dachas, as well as in zamіskih booths through parts of interruptions in electricity supply at such facilities. Such systems are mentally divided into two types - with the lower and with the upper supply of water. To assign the type to the type of the opal system, it is necessary to look at their intelligibility, characteristics of that area of stosuvannya.

Principal scheme of scorching from the natural circulation of heat

Impregnation systems with top water supply

Heat-carrying - at the same time, water - for heating and supply at the upper part of the scorching system behind the auxiliary pipeline. The pipe, which is installed for supplying water, is to blame for the large diameter of the pipes, which is supposed to supply water to the radiator. It is necessary to reach the maximum support for heat exchange. Horizontal pipes should be installed with a minimum offset at the boundary of one centimeter per meter.

It is necessary to install an expansion tank at the upper part of the system: if we have the function of receiving steam and excess heat, it is necessary through the power of the water to expand when heated and go to the camp of the bet. The presence of a pouring faucet and a lid or a valve at the upper part are to blame on the tank. After that, as the water is heated, it flows through the pipe, which is supplied, to the vertical risers and into the radiator.

Porada: if you choose to vicorate the scorch system with natural water circulation, remember that the radiators must be connected to help the diagonal method

After the uninterrupted scorching of the water, the water passes at the boiler with a special pipe - wrapped. Here it starts up anew and the cycle of traffic is repeated. The boiler for heating is installed in the lowest area of the system under radiators. As a rule, these elements are installed in boiler houses, for which there are basements.

Impregnation systems with bottom water supply

The system, in a kind of heat-bearing capacity, is supplied from below, ringing vicorist for singing the houses, depriving it of a mountainous place, otherwise access to the new one is closed. The main feature of the scorching system is that the pipes are laid under the radiators. Also, there is a expansion tank, which is installed at the upper level of the system; ring out at whom the government's appointments will stop. As if at any time the circulation of water in the system of scorching, as it may naturally occur, it becomes a primus path.

The standard scorching system with primus circulation functions for the help of quiet connection methods themselves. Vіdminnіst polyagaє in the fact that through the great length of the cycle of the system, or the presence of natural minds, it is necessary to include a pump in the system to fold the pipes. The pump for circulation is mounted to the main pipe, which helps to increase the terms of operation of the opal system. The vikoristanny of the pump helps not only to increase the efficiency of scorching, but also to shorten the number of mains. A system with primus circulation can heat up not just a sprat, but also build houses with a kilkom on top.

In order to rob Yakіsnu work which type of system needs uninterrupted power supply. Installation of a pump for circulation in the scorching system is required in order to primus create water circulation in a closed circuit. AT given type Pump systems are the central component of the environment. It should be noted that the circulation pump may not be affected by significant productivity: this pressure is necessary only for directing the flow into the pipe that is being supplied. Tsey napir shtovhaє water at the gate directly, shards the system is closed.

Circulation pump required uninterrupted work scorching systems, this is due to the fault of the systems, in which the installation is victorious. Because of its functionality, this type of pump can be found everywhere in the most demanding pipelines.

Selection of circulation pump for scorching system

To select a circulation pump for the opal system, it is necessary to perform a decontamination. To restore respect, that by the end of the year, this element will run out more water, lower the volume of the system. In such a rank, the total consumption of the required amount of water in the average is 10 liters per 1 kilowatt of pressure of the scorching boiler. The required model of the pump for the opiate system and its pressure is determined by pressure-vitrate parameters. For example, he is guilty of adding hydraulic support to the opal system.

Sound the speed to the pressure of the radiator in the systems primus circulation to do low, which allows you to judge about the low cost of the hydraulic support, as if it were sounding to move 2 meters. It is not easy to calculate the exact opir of degreasing; therefore, the productivity of the circulation pump is the middle point. In order to increase the productivity, one also needs to increase the area of the object of scorching and exhaustion, which was the source of electricity. Keep in mind that the pump is only required in a system with primary circulation, a system with natural circulation is not required.

Installing a circulation pump: what is the next step?

To install the circulation pump yourself, please follow these recommendations:

- To continue the operational term of the system, install a filter in front of the circulation pump to clean the radiator. the filter must be installed on the suction pipe;

- Do not choose for the opalescent system a circulation pump of high pressure and productivity, lower required. In the other case, the fault of the rizik is stuck with additional unacceptable noise during yoga;

- Do not let the pump in before you fill up the opaluval main with water and remove it from it again, otherwise you can bring it to the end of the exploitation;

- install the pump in the area as close as possible to the expansion tank;

- If the pump is connected to a closed scorching system, install the pump on the gate. Why is it due to the fact that the yard of the main line may have the lowest temperature.

Porada: before starting the scorching unit, it is necessary to rinse with water to remove various foreign particles. Do not forget that running a short-stroke robot of the circulating pump at idle due to the presence of water in the system can turn into an output from the fret of the pump itself and other elements of the system.

May all circulation pumps, presented on the current market, be provided with automatic control of boilers for heating. This function gives the sorcerers the ability to regulate the temperature again on the objects that are being scorched, for additional change of speed, drive in the scorch system. In order to protect the balance of heat in the premises, special heaters are installed to control the heat input, which is blamed on the wear of the mains. The scheme of scorching itself does not give rise to regular changes.

You can learn how to install a circulation pump on your own by watching the video:

Scheme of the vlashtuvannya of water burning.

The reasons for the filling of the opaque system can be: emergency situations, Through the yaks, I happened to anger the water, seasonally throwing off the water, releasing the damaged traffic jams.

Before that, start up the scorching system with water, especially if it is the first start-up, it is necessary to run it. The middle of the structural elements of the system may know the excesses of the factory vibration - chips, which preserve the reagents.

Even though the filling of the system was not carried out earlier, then in the pipes for an hour of service, unsafe for the right work of speech, such as scale, vaporous stones, accumulated. All products can cause serious boiler failure and all systems.

Flushing the system before starting

Scheme of water burning

Like in the scorching system there is water, it is necessary to anger. Then follow. Let's connect the pipes to supply water from the water supply system to the exit from the system, and the water - to the entrance to the system. It is necessary to fasten the fastenings of the day with well-prepared collars. The next thing to remember is that with a greater pressure water is supplied, the more quickly the purification will pass (although no more than two atmospheres). To close the vise, sound the vicorist pump. You can add chlorine to the water to achieve a disinfectant effect. For an average person, this procedure can take up to two years. After the end of the zlivu pide clear water without additional houses.

Purification of the scorching system can be carried out with the help of special chemical agents: additives or anti-corrosion agents. Before them, the varto is placed with care, the stinks of the stink are not suitable for all materials and can harm the elements of the system.

After cleaning, the installation of radiators is carried out at the gate directly for dismantling. Slid additionally to check the tightness of the system by means of visual inspection and detection of leaks.

How to designate the amount of money for the system

Scheme of a two-pipe system of water scorching from natural circulation:

1 - heater; 2 - main riser; 3 - expansion tank; 4 - hot water line; 5 - risers of hot water to radiators; 6 - scorching radiators; 7 - downpipes of chilled water; 8 - line of chilled water (return); 9 - pekti.

In order to avoid excess water overflow into the scorching system or non-scorching water, which can lead to the destruction of the structural elements of the system, evacuating water, removing scale in pipes and radiators, it is necessary to accurately decompose the necessary volume of water. For this reason, the formula is simple, in order to sum up the capacity of all radiators, the scorching boiler, the expansion tank and other additional elements for passing water, zokrema pipes. The formula for expanding the volume of water in pipes is advanced: π (3.14) × r pipe × total pipe length. Before blatant significance add close to 20% as a reserve.

You can determine the necessary water supply in order to start the system, you can wash it for an hour by setting the water meter at the entrance to the system. Indicated in the world of zapovnennya system slid memorize and vikoristovuvati pіd hour zapovnennya.

After that, as everything is ready before the system is loaded, the next step is to prepare or check the list of necessary materials and tools again.

For whom do you need the following materials:

- gaskets (on the vapadok, as it is necessary to strengthen the sealing of pipes after rechecking the tightness of the system);

- sealing lines for pipes (to serve for usunennya drіbnih tech zvnі);

- hoses (required for supplying water to the vibration pump and supplying water to the scorching system);

- plastic container (tank - for a set of heat transfer before pumping it out of the scorching system);

- clamps (required for sealing hose connections with a vibration pump).

Tools:

- pliers (necessary fixation of clamps on the hoses of the original attached to the pump);

- on-butovy vibrating pump (primus pumping water from the tank into the scorching system);

- manometer (with this help you can easily measure the flow pressure of the system).

Classification of scorching systems

A simpler looking system with upper pipes. In such a state of mind, one hour, for the sake of protection, to open up the insults of the shutters, when you drop off, you can close it. In order to bleed the wind again, they climbed on the hilltop and saw the cranes again, transferring the structure.

The process of launching a critical gravity scorching system

At modern booths open system scorching power is rare, such technologies have long been vvazhayutsya a relic of the past. Ale stink є, then look at it, as it is necessary to fill them with water. Have a similar opaluval system - an expansion tank at the top її point, vin appointments for the accumulation of water after an increase in її volumes in the system with a greater pressure on the increase in temperature. The tank is filled with a reservoir with a lid or without it. The system is filled with water through the tank. It’s problematic to fill the big belts of the native land, obviously, with a deep container, even to the very top point.

The most rational vikoristovuvatime primal vibrating pump of the by-button type. For whom they are preparing a place for a place, reminiscent of water. Before the pump, fix the hoses with clamps. Such a pump can be a boring type of life. The hose, through which the water intake is carried out, must be lowered into the preparation tank with water. The hose, for which the drive outlet should be vibrated, is laced up at the expansion tank. Turn on the pump, the pressure on the system can rise to two atmospheres. If the water is too low, add water to the preparation tank and lower it lower into the new hose. If the opalizing complex is filled up, the water will be remembered at the bottom of the expansion tank, you can put the filling system in.

Scheme for the installation of the heating system.

Overflows will be seen again from the pipes at the first top through the expansion valve. It should be noted that it is the first hour of the opalescent season, if the temperature is constantly high in the system, the water is progressively evaporated from the expansion. It is necessary to carry out refreshment, adding water to the expansion to the required level. Keep track of the temperature on a thermometer attached to the scorching pot. At the reach of її equal to 80 ° C, the water will suddenly boil and swell. In such a fall, it is necessary to block the access of the sour to the firebox to reduce the intensity of the fire.

Filling a closed scorching system

I will close the scorch system in the most part. Vіdminnіst її vіd vіdkritoї polagaє budovі expansion tank. For a closed opalizing complex, the hermetic expansion and filling of the system is carried out in a different way.

Cooking for the cob required materials and tools. Including: a volume tank, hoses for pumping water from the tank into the system, clamps for fixing the hoses, pliers for installing clamps, a vibration pump, to fill the system with water.

Scheme of visual inspection from the scorching system.

Before pumping, it is necessary to hermetically seal the pump with prepared hoses for additional clamps. Prepare the tank to fill it with water and roztashuvati the tap of the filling system. The pump is also guilty of a charge. The hose that takes water should be lowered into the tank, and the hose that supplies water should be secured with a clamp on the filler tap. Cranes and shutters for rozpovіtryuvannya opalyuvalny complex can be buti vіdkritimi. Turn on the pump and start supplying water to the pipes. On the pressure gauge, the vice can increase step by step. If the entire circuit is completed, the indication of the pressure gauge is due to reach two atmospheres. After the pump is turned off. Remove the hoses and shut off the filling cock.

There is no possibility to use a pump for filling the opalizing complex, it can be pumped up with a water pipe. The milking scheme is similar to the one described above. It is enough to attach one end of the hose for water intake to the water supply tap, and the other end - to the filler in the system and progressively inject the filler into the system, and then the water supply. Behind the vice at the time, the stitches can be added with the help of a well-kept pressure gauge.

The final operation of filling the system with water was to remove the winding from the circuit. AT current installations transferred special outbuildings for such a method. You can check the system by using the vicorist attachment on the bypass.

http://youtu.be/7tOnKzLcV-U

The filling of the opalizing system will be most efficient when two people are working, the stones will need to be simultaneously pulled through the entire filling process to control the pressure in the system and the pump robot, by changing the pumping crane, and following the tightness and ventilation of the radiator.

Viewing broken traffic jams, starting the scorching system

Scheme of removal of damaged plugs from the scorching system.

Regardless of the outside filling, the scorching complex can accumulate more and more, which in the future will lead to corrosion of the internal parts of the pipeline and radiators and cause constant noise and rattling of the system. The wind is left in the pipes through the presence of many turns again in the water that starts up, and the seals are not hermetically sealed.

In order to release the fire again from the scorched pipes as soon as the filling is done, it is necessary to open the doors again and the taps and bud up to three years. It is not necessary that the mustaches of the bulbs from the inner walls of the scorch fittings were lifted to the surface and opened through a special opening. Make the process easier than using a vibrating pump. After the process is completed, it is necessary to close all shutters and create the necessary pressure for correct operation in the system, the fault is to be found on equal atmospheric repetition. Virіvnyuvannya vise zrobiti path pіzhivlennya - adding a lot of water, scho marriage. After the launch, the vice will rise to two atmospheres.

Now you can start the opalation complex. As soon as the scorched new one is launched first, then for the minds of the warranty service, please the robot to kill the facsimiles of the authorized service centers of the harvester. Repeated launches should be carried out independently. Know the opiate complex by progressive heating during the day. Although no shortfalls were found in the scorched complex, it can be found on full of tightness. Varto signify that the first two robots of the system can be accompanied by rattling at the pipes. It’s not guilty to be on the alert, don’t let the shards out every once in a while when opening, it’s self-sustaining in the process of work.

Must-haves come in next time to spend before the opaluval season.

No related posts.

Most Popular Blog Articles of the Day