Why roble heat shrink. How to choose the required diameter of the heat-shrinkable tube

For the right choice heat-shrinkable tubing is necessary to protect a large number of powers that lie in the minds of further exploitation at the warehouse complex of possession. Naygolovnіshim technical parameter be-like heat shrinkage є її diameter. Incorrect selection of the diameter of the tube can cause up to її poshkodzhennya during shrinkage or in the process of exploitation, do not allow the world to win all the feasibility of the tube, which is thermally shrinkable. In the most recent case, the thermoset tube is simply not available for the virib. Correctly, the pipe was picked up - a guarantee of supremacy and long-term exploitation.

For the correct selection of the diameter of heat shrinkage, it is necessary to follow a number of simple rules:

1. The minimum diameter of the tube (object) for which it is planned to install the tube is due to at least 10% more, lower the minimum internal diameter of the over-shrinked heat-shrinkable tube at the free stand.

Comments: This is important, so if the heat shrink tube is not worn, it will be virulently bound, the spring forces of compression, which will trim the heat shrinkage, will be small, the tube can be even more German trimmed on the surface of the tube and wind it up.

The optimal result is achieved when the diameter of the insulated tube is larger than the diameter of the planted tube by 20-40%. With these values, the tube, which is heat-shrinkable, is completely safe to lay in it the characteristics of mechanical and electrical strength, durability, temperature stability.

Yakshcho diameter Virobu, Sho іzol, wake up more than 50-70% of the minimal intra-nickel di-meter of the village of thermosajuvan tubes at the VILLENTA, then the situation is allowed for implicitly, close to the maximum sizes for the most visible. . In another case, at high operating temperatures (at + 90 to +125 ° C), it may be possible to open the heat-shrinkable tube through those springs that compress it to the opening. So you can succumb on your own operational characteristics tubes.

Opening the tubes can be done at the moment of shrinkage, especially at the shrinkage temperature, which exceeds the recommended one, so the shrinkage of the tubes on such a large scale should be carried out properly, at the minimum possible heating temperature.

2. The maximum diameter of the pipe (object) for which it is planned to plant a tube, is to blame but at least 10% less, the lower internal diameter heat shrink tubing before shrinkage.

This rule is dictated by us before the very possibility of stretching a non-shrinkable heat shrink tube onto the object before shrinking it so that the tube itself is not damaged. For applications with a folding surface relief, this parameter is to blame for the possibility of bringing it up to 20-30%.

In addition, with the inner diameter of the tube before shrinkage, it is less than a troch to exceed the diameter of the tube, it is possible to suffer in the process of shrinkage or further operation at higher temperatures. (Div. comment before the first rule).

More heat-shrinkable tubes can have a double shrinkage factor. What sound is sufficient for the selection of the required size of heat shrinkage for any choice. However, there are fluctuations, if the insulating object (detail) has a folding relief on the surface with great differences in diameters, for which one does not dare to pick up the phone to follow all the recommendations.

For example, it is necessary to insulate the area between a thin cable and a thick rose, fix it on a new one. You have to stand in front of a choice: otherwise the tube is not tight around the surface of the cable, otherwise we cannot pull the tube on this rose!

An example of a simple rozrahunka:

It is necessary to put an insulating heat-shrinkable tube on a strum-conducting tire of a round cut with a diameter of 10 mm, which is operated at room temperature. Max. tubes of offensive diameters (before / after shrinkage): 20/10 mm, 19/9.5 mm, 18/9 mm, 16/8 mm, 13/6.5 mm, 12/6 mm, 11/5.5 mm 10/5 mm.

Oskіlki temperature exchanges are not possible, then we follow the rules of 10%. Tubes 10/5 and 20/10 are thrown out at once. In the first case, we cannot pull the tube onto the tire, and in the other case, after shrinking the tube, the diameter will be more than 10 mm and it will not be possible to compress our virib.

According to rule 1, the internal diameter of the overly seated tube is to be at least 10% less than the diameter of the tire, that is. 9 mm or more. This value is not supported by tubes 20/10 mm and 19/9.5 mm.

According to rule 2, the inner diameter of the tube before shrinkage is to blame but not less than 10% more, the lower diameter of the tire, tobto. not less than 11 mm. In this order, all the tubes that were left out: 18/9 mm, 16/8 mm, 13/6.5 mm, 12/6 mm, 11/5.5 mm formally fit as insulation for our tires.

To follow the supplementary recommendation that the most optimal is the drop, if the diameter of the seated tube is 20-40% less than the diameter of the pipe that is being insulated, then the optimal diameter of the tube after free shrinkage is to be 6 to 8 mm.

Such a rank, the best solutions for the insulation of our tires will be tubes 16/8 mm, 13/6.5 mm and 12/6 mm. And how can you choose among them for you depending on their obviousness, necessary preparation, accessibility, economic dosilinost, even pipes of smaller diameter, as a rule, are cheaper.

?

Thermal tube - a tube made of polymeric materials, which squeezes in the diameter after heating. Glue ball fixes the tube on the dart or cable. The tube can also be wrapped without an adhesive pad. The process that combines a cable and a thermal tube is called insulation.

For what purposes is a thermal tube installed?

The thermosetting tube is victorious for replacement of insulation, for protection from the outside inlet, insulation and marking of pipes. Thermo-tubing electric darts that cable in an aggressive environment, for example, water, oliya, acid, as well as protection from the influx of external negative factors dovkilla. The thermal tube is an alternative to conventional insulation methods and can be used in various applications.

Why polyolefin tubes shortest choice from the last row of heat-shrinkable tubes?

Polyolefin heat shrink tubing is a popular choice in the middle choice of heat shrink, because polyolefin is fireproof and has good chemical, electrical and physical characteristics. In general, polyolefin heat shrink tubing is the best product available technical helpers zamovnikov in guaranteed capacity. Thermal tubes are available in different sizes for different purposes. The polyolefin thermotube is the best choice for stasis in the automotive industry. However, depending on the specific application, the characteristics of the other thermo-tube may be more suitable for your needs.

Chi is easy to work with tubes, what are they heat-shrinkable?

But, as a rule, the thermal tube is also simple in operation and in installation.

The thermosetting tube is produced at great variety of sizes and colors. For work, it is not necessary to have serious training and high performance, expensive possession. More than necessary mittens and tools, indications in the instructions.

What are the advantages of using a thermal tube?

Crim for the safety of the supplementary temperature and thermostability, the thermal tube also gives the ideal protection and does not blow after the end of the song hour, or the wrong vikoristannya - on the vіdmіnu vіd іzolenti.

What are the important parameters of the following vrakhovuvaty for the hour of choice?

The maximum diameter of the cable or yogo knot and the temperature allowed for work, є important parameters, yakі sld vrakhovuvat when choosing a thermal tube. Some of the parameters of various pipe makers HERE are significantly changed, it is necessary to change the process of bending, sewing and power of the outer material, vicorous for the manufacture of heat shrinkage, as well as the final characteristics of the product, the shrinkage coefficient and other moments.

How to determine the tube shrinkage coefficient HERE?

Shrinkage coefficient refers to the change in heat shrinkage diameter at the time of delivery and shrinkage diameter at the time of new shrinkage after heating. Kіlkіsno, sіlka razіv sidає tube.

2:1 - In this case, the thermal tube will become smaller in diameter from its cob size when heated.

3:1 or 6:1 - Heat-shrinkable tubes at the time of delivery are three to six times more, more, more, lower at the station of new shrinkage.

Before speech, the moment of complete shrinkage of the tube is discussed, the tube is more likely to be set not to the limit of possible expansion, but by a maximum of 30-60%. Tsya umova gives the best shrinkage result.

How to choose the right size for heat shrink tubing?

Selecting the correct size of the thermo-shrinking tube to lay down according to the accuracy of your measurements of the insulated material. Vykoristovyte exactly fit for vimiryuvannya the smallest one the highest value cable diameter, wire diameter, steel pipes, yakі You can namir іsoluvati Choose heat-shrinkable tubes, which are twenty or thirty hundred thousand more, the lowest value of your measurements. The price of the difference is sufficient for a free tension on the surface, which is insulated. Also, be sure that the heat shrink tube can achieve a high shrinkage factor, in order to take away the embossing and for the smallest diameter, which you can insulate. Nareshti, when buying heat shrinkage, it is necessary to take 10-20% more than the length, because the heat shrink tube changes not only in diameter, but even in length! Tsya akіst is called “lower shrinkage” and in the fallow of the diameter, the coefficient of late shrinkage increases.

Hosted by the company

Heat-shrinkable tube (abbreviated HERE) was found in the 50s of the last century. We took away її zavdyaki changing the molecular structure of polymers.

Call it in a different way: thermoshrinkable, thermoset, thermocambric or just a thermotube. The essence is changing, the shards are the same ones themselves.

The main tasks are the isolation of contacts, the protection of the cream, and the additional methods for the installation of such devices:

- shrinkage on the butt of a wooden or metal support of a power transmission line for protection against corrosion and rot of a village near the ground

- insulation from the aggressive core of metal and water pipes

![]()

The shrinkage of heat shrinkage is grounded on the effect of the memory of the form. They reach with a path of radiation prominence.

If, for example, the polymer is placed in an exhausting flow of electrons, then on the molecular level, there will be a combination of suicidal macromolecules among themselves. This technology is called cross stitching technology.

After the operation, the polymer itself becomes more elastic, and when heated, it expands its cob form and cob expansion.

Theoretically, that very tube can be planted for a number of times. Yakby you have a buv attachment for її playing that rozdmuhuvannya, then it would turn into a virіb of bagatora vikoristannya. Moreover, the term її saving from the cob mill dozens of years. Usі characteristics that akіst virobu for dotrimannya sevnyh could not fall іstotno vіd date preparation.

On this day, the heat-shrinkable tube nabula of majestic commercial and technical significance in the world. However, the main areas of zastosuvannya are the areas of electronics and electrical engineering.

Thermotubes are more efficient than the best cambric, yakі mayut brand TV-40. The cream of technical stability of the stench may be even more chemical. And it allows you to protect the insulation and contacts at places with aggressive media - under the ground, at wells, cable channels.

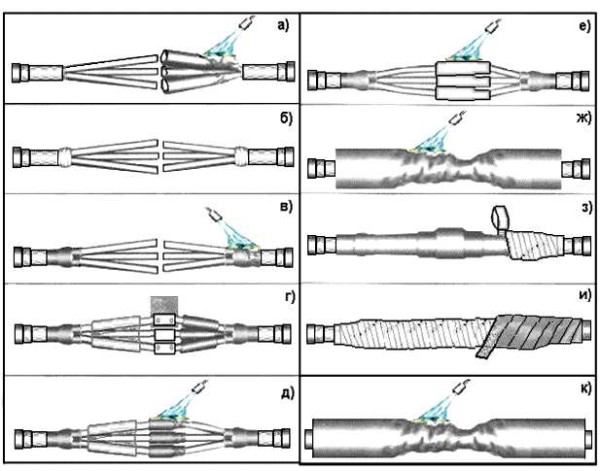

Vidi heat shrink

The axis of the main types of heat-shrinkable tubes is widely zastosovuyutsya in the industry (from the KBT company), their characteristics:

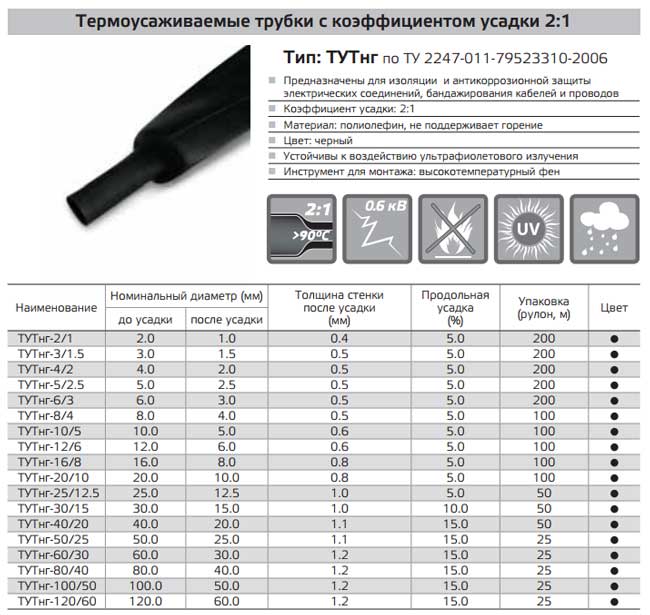

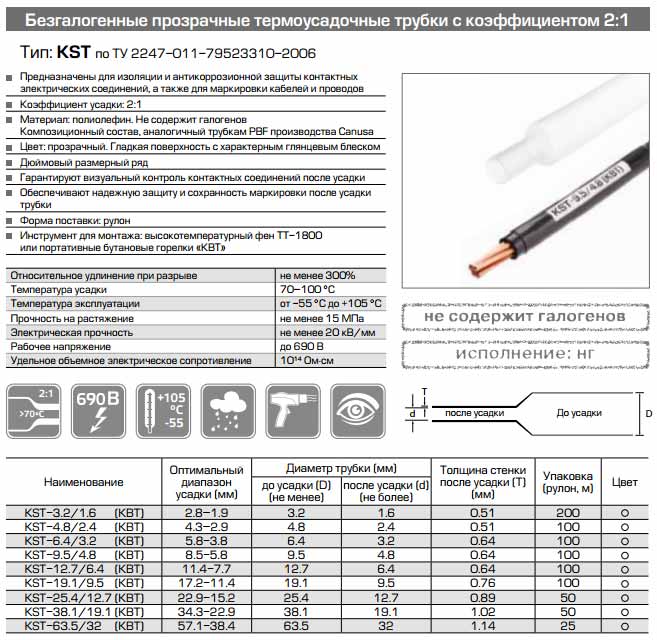

Thermal tube TUTng 2k1Prozora tube KST 2k1Color tubes HERE 2k1Yellow-green TUTng w-z

Yellow-green thermal tubes TUTng Zh-z

Yellow-green thermal tubes TUTng Zh-z

Products and high-voltage brands of heat shrinks:

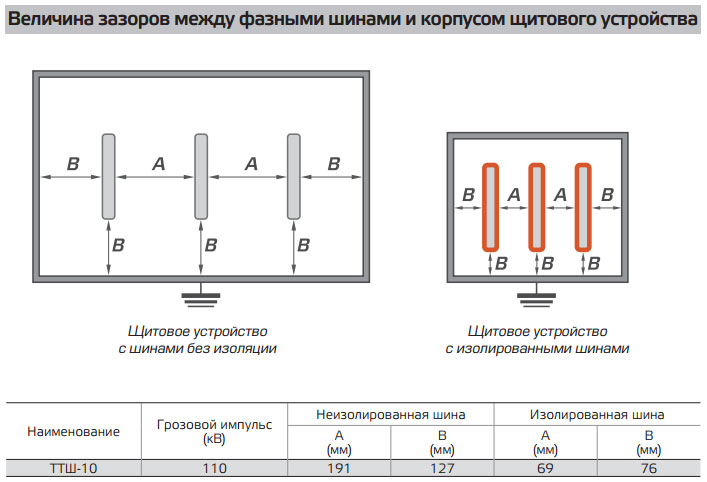

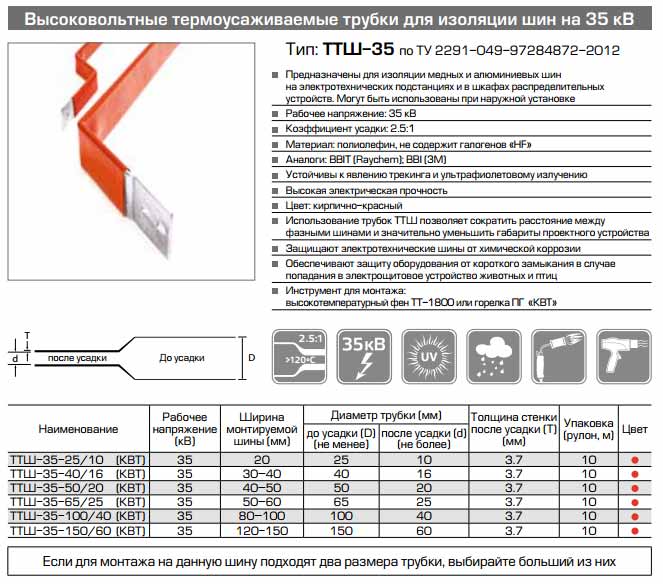

Tovstostinna TST 3k1Antitrekingova TST-A 3k1Tovstostinna non-combustible TT-S ngHeat shrink string TLK-10Tube for tires 10kv TTSh-10Tube for tires 35kv TTSh-35

![]() Tovstostinna TST 3k1

Tovstostinna TST 3k1

Heat-shrinks for special wicking:

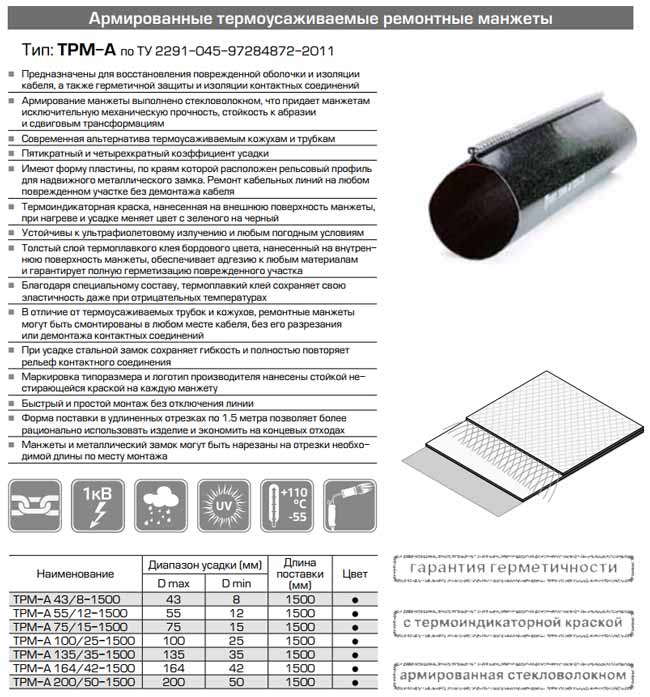

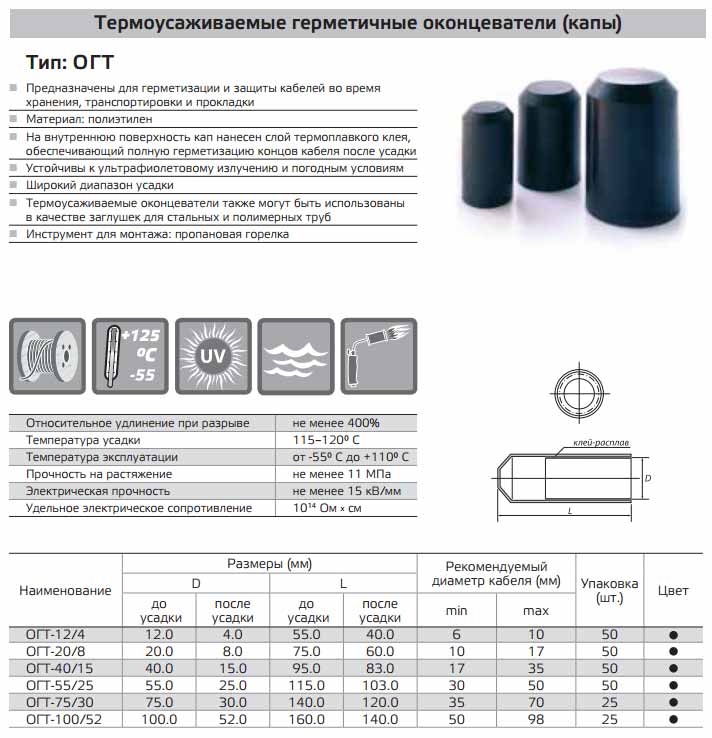

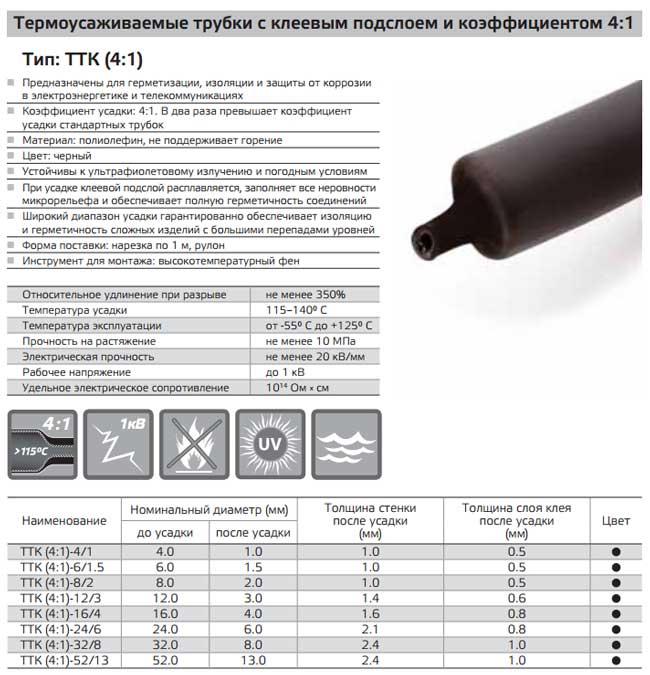

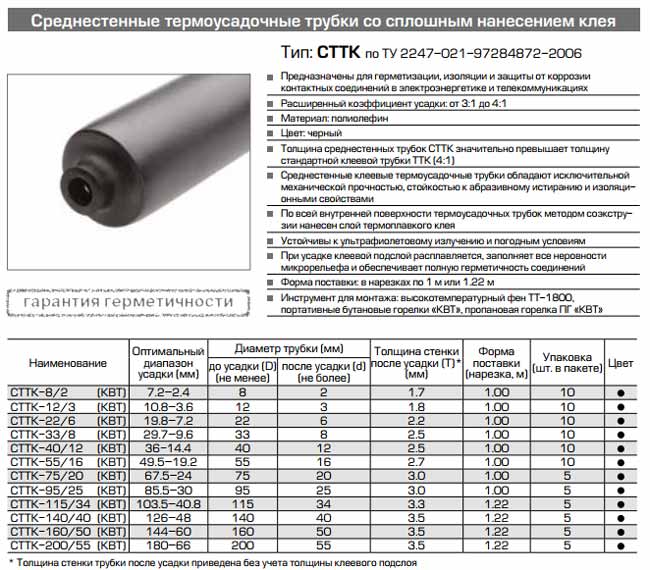

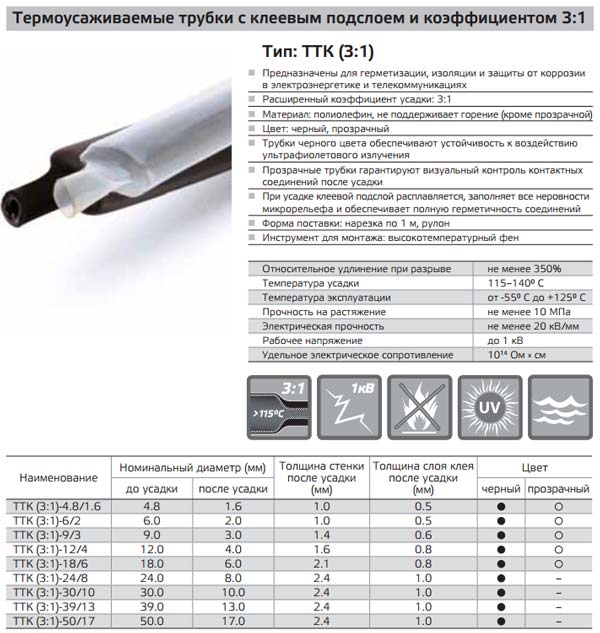

Repair cuffsReinforced cuffs Cable caps Heat shrink 6k1 Casing With glue ball TTKMiddle East STTK

![]()

Characteristics and power

How are heat shrinks used and how do they smell like one in one?

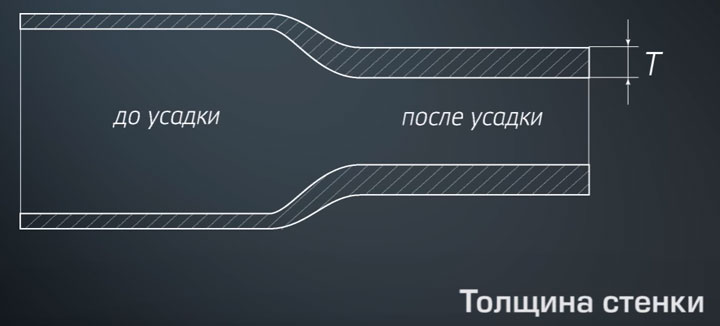

Diameter before that date

The thermal tube changes its diameter when heated. To that, in the name of the zavzhdi, buti rosemir BEFORE and PISLYA shrinkage is to blame.

For example tube HERE NG 40/20

- inner diameter 40mm - DO

- total shrinkage diameter 20mm - PISLYA

Shrinkage coefficient

The next criterion is the coefficient of shrinkage. What is it? Tse spіvvіdnoshennia of the primary diameter to the diameter after the shrinkage process. Tobto, zalezhno vіd koefіtsієnta, the tube changes in kіlka razіv. Buy coefficients:

- 2 to 1

- 3 to 1

- 4 to 1

- 6 to 1

Chim vіn more, tim vibrіb fold more prepared. Obviously, their prices are different. However, tubes 4 to 1 are considered more universal, lower 2 to 1.

Yakshcho you will join two darts of different cuts and different comrades, without heat shrinkage with great coefs. you can't get by.

Tovshchina of the wall

Thermotubes can be used as a basis for the fabrication of the wall. According to these criteria, stinks are divided into:

- thin-walled

- middle

- tovstіnіnі

In addition, the thermotube is glued - TTK brand. Tse that on the inner surface for applying a ball of hot-melt adhesive. When heated, the glue melts and fills all the microvoids, thereby ensuring a completely sealed seal.

Walls stick practically to the surface. Surpluses of glue may protrude along the edges when tsyomu.

Replace such a hot-melt adhesive, with a path of front coating of the inner walls of a simple tube, do not go into it. The wine is applied by itself for її preparation. In addition, the adhesive coefficient of heat shrinkage is greater, the lower one is 3 * 1 or 4 * 1 against 2 to 1. more voltage for the rahunok of the comrade's walls.

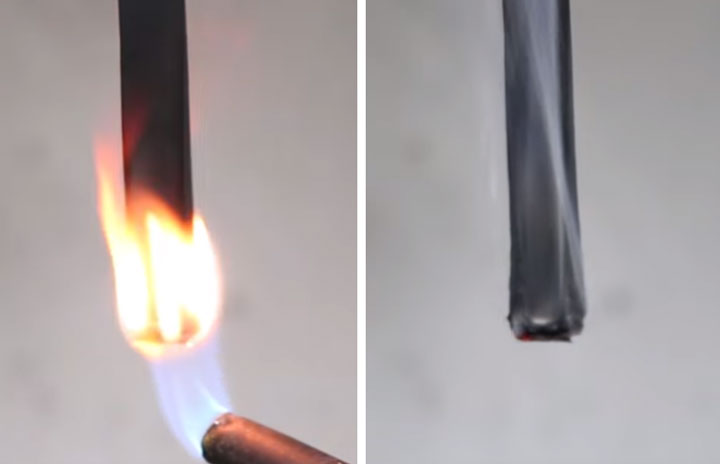

Non-combustible

The material is of great importance, from which the choice is made. The very beginnings of the composition of the composition of the material, the back of the line are asked necessary authority. If, for example, fire retardants are added to the warehouse, then the tube becomes self-extinguishing and is indicated by the NG index.

It does not mean that we are not going to burn. Ale, for the appearance of the splendid dzherel, the half-light is suddenly extinguished. Take care of the path of zabіgannya nadhodzhennyu sour to the point of burning with flame retardants.

To pay attention to the fact that the VVGng cable is used in the case of the VVGNG cable, then it is necessary to insulate the contacts that are made by the thermo-shrinkable cable with the NG brand.

It is no longer possible for this type of person to beat the best cheap option.

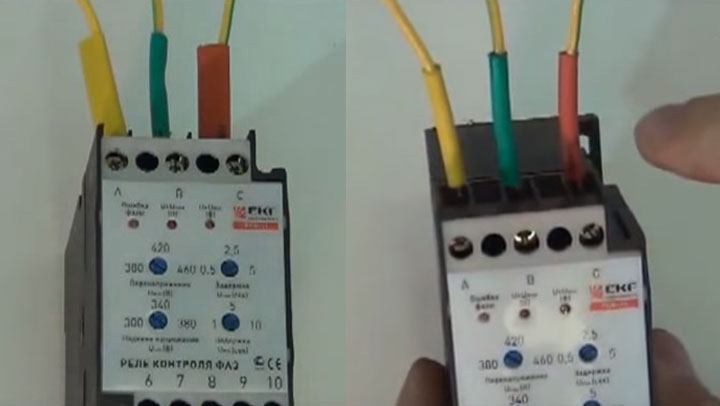

Color

Thermal tubes come in different colors, including gaps. The stench is more important to serve for branding.

With them, you can easily mark the end of the cable, as if you were trying to trim the old rules for the color phase designation. To finish the okremі shmatochki planted on the kіnets lived.

For phases A-B-C buy Zh (zhovty) -Z (greens) -K (red).

And the axis for the new GOST fA-fV-fS is given to the colors K (brown) -Ch (black) -S- (siriy). Here it is already possible to win the openings of the pipes, or to bathe in prayer.

There is also an original appearance from a variety of different-coloured adhesive tape, over which a thermal tube is applied. So the phases will be marked already according to the new rules.

If you don’t need the color designation of the phases, take black. The stench is cheap, but the insulation itself is the same.

The price is related to the specifics of the technological process. After a skin pass of one color, repair the auger from the old material. And tse yakraz i vplyvaє on sobіvartіst.

Є th dvokolіrnі virobi yellow-green color. The stench is designated for grounding darts.

If you want to control and monitor contacts after installation, we can help you with a tube on the right side of the gap. Just be respectful. The gaps will no longer be unoccupied gaps. Shards to add fire retardants must be produced until the color is changed.

In order to write and mark the darts, under the openings of the tube, often insert a paper with numbers and signs. After shrinkage, the mark is unmistakably visible. In this way, you can specify the brand of the cable, yogo peretin, which vin to live that richly іnshoy.That power of self-extinguishing and transparency is not in the least here.

True, in this way, it is better to heat the heat shrink with a hair dryer, and not with a palnik. Otherwise, you can vipadkovo poshkoditi yourself wrote.

Also, heat shrinkage is applied on the conductor and vibrating the tension of the electric field.

And yet, most of all, the electric insulation is the most victorious for us. The stench zastosovuєtsya material with high electrical insulating power and the stink mayut high electrical power. Moreover, the higher the electrical power, the greater the class of the voltage of the stink of the insurance: up to 1kv-10kv-35kv.

Irrespective of those that the tube, which is heat-shrinkable, has been found in the last century, there is still an abundance of innovative products on the electrical market. You can choose your own sets of thermotubes.

For superior insulation of electric darts, it is possible to select a few types of materials. Before them comes a classic insulating line, prepared on the basis of dielectric polymers. And in the rest of the hour, thermal tubes/couplings were especially popular. The stench is simple in installation and may be garni operational quality.

Designated and technical characteristics

The stinks of the stench are predicting plastic insulating ball. Ale on tsmu їhnya similarity ends. Termozbіzhnі mufti (ТФ) are recognized for the creation of a superficial ball of heat in the areas of installation of electric wires.

The principle of blocking TF power cable until the moment of stukovannya strumovedchih alive. After the s'ednannya shell is brushed over the stick. At this end, the muftis are to blame for the insulation of the cable. Further, for the help of a commercial hair dryer or a gas burner, the temperature on the surface of the TF is moving, after which the diameter of the virobut is changing and compression is being made on the surface of the heat pump.

Such a principle of installation has become possible for the production of materials - a polymer based on polyolefin. Depending on the temperature, there is an increase in the density of the material, after which the dimensions change.

The main technical characteristics of the thermal coupling є:

For marking wires, you can put a muff of a different color. A lot of models are processed by a glue warehouse in the middle. At different temperatures, the veins will increase the insulating power and additional factor of the superficial fixation of the muff on the surface of the dart.

Advantages of congestion and installation rules

Cream insulation electrical cables termozbіzhnі tubes zastosovuetsya when laying pipes sewerage and water supply. However, their design is similar to that described above. Most of the stench is formed from a large number of warehouses, the installation of which is carried out in stages.

Cream insulation electrical cables termozbіzhnі tubes zastosovuetsya when laying pipes sewerage and water supply. However, their design is similar to that described above. Most of the stench is formed from a large number of warehouses, the installation of which is carried out in stages.

For the completion of the technology for the installation of TF, it will ensure the onset of insulation:

- Mechanical science. Zavdyaki vodnosno great zhorstkosti evils drotu near the place of installation is practically turned off.

- Nadіyny zakhist in vіd vіdannya vologa. This reduces the possibility of corrosion on conductors, as well as reduces the severity of oxidation of contacts.

- Electrical insulation

The installation of a thermoset tube is clumsy. For yoga to be carried out, it is necessary to prepare the darts in advance, which will start. After stripping the ends from the insulating ball, the galvanized dozhina of the wiring is removed, where it is necessary to install the TF. For rich-core darts the best way to get a new set, for example, pipes of various comrades. It is selected according to the diameter of the skin cable. After squeezing the diameter of the TF, it is the fault of the smaller ones for the overrun of the drive. For example, for living with a communion of 2.5 mm, a coupling with a diameter of 3 mm is required from a KU of at least 2.

The leather component of the cable is to be insulated okremo. On the butt cover instructions you can choose the order of insulation of a 3-core wire.

After vikonannya robit kozhna z dіlyanok is checked for tightness and tightness of the connection of the muff to the cable.

Vartist TF without intermediary lie down in their mind, rozmіrіv that complete set. The price of one set of virobs of various diameters is 600 to 1300 rubles. The purpose of the professional set of European manufacturing. Postal sales are rare. Zagalom 1 m.p. koshtuvatime vіd 30 (2.5 mm) to 90 (35 mm) rub.

When choosing the following, respect for the geometrical design of the viroba, the comrade of the wall and color marking. Also, the next vrakhovuvati shrinkage coefficient.