Vaga cement-fed. Choose materials and cook sumish. SNiP cement-food screed

Cement-screed screed pidlogi - traditional and time-consuming way to virіvnyat pіdlogi, build a new basis for pіd tile, laminate, carpet.

Familiarization with the technology of organizing a new article in the appli- cations of different countries.

Cement-pasted screed is universal, and it can be fixed on any surfaces: concrete, stone base or base on a stone base.

Warehouse sumishi

For the preparation of a variety, it is rare to add vicarious components: enough of two, guessed from the very name of the method. Standard sizes are prepared in proportion: one part of cement M 300 and 2.5-3 parts of sand. The third binding component is water. For zbіlshennya schіlnostі cement- food screed retailers recommend adding plasticizers.

IMPORTANT! As a cement-screed, the screed is victorious for organizing underlays in applications with a high intensity of mechanical inflows, the screed is viconated from the cold (reinforced screed).

Picture 1 - Proportions of components for the preparation of cement-food mix and concrete (sizes M 150 and M 200)

With a clear pre-treatment technology, the cement-food screed of the building is vitrified by the pressure from the point tension of approximately 500 N/cm2, communities and occupied with a high intensity of traffic (pishohidna, car zone).

Cement-food screed: vitrata materials

Conducting a fundraiser before purchasing budding materials, ensure that for the organization of a traditional 4-centimeter screed, about 7 bags of cement are needed (it will be enough for a room of 13 m²).

With proportions of 1:3, it is necessary to add more, tobto. 21 bears (wrap, which is often sold less in 50-kilogram bears, in that hour, like cement - in bears of 25 and 50 kg).

Vaga cement-food screed

Before that, how to start a grand commotion at home or in the office, change your mind, so that the application of the construction of the screed should be taken care of: you can choose a more easy option - for example, dry the screed instead of the wet one, or put on the dry fiber screed.

Take, for example, cast-in-place concrete structures in a frame-monolithic life. Takі according to SNiP vitrimyut close to 400 kg / m² yak constant ambition and more 150 kg / m² - yak timchasov. A screed with a thickness of 5 cm will give an additional advantage on a charge of 90 kg / m². Non-leather budova is covered for a brute-force carrying capacity over a maximum of 25%.

Before that, how to proceed to work, rather consult with fahivtsy or, more briefly, - to solidify the plan for staying with the relevant organs of the medical self-regulation.

When rozrahunka vaga screeds important vrakhovuvat, scho itself understanding "vaga" can not be seen one-sidedly: there are two hypotheses - pet vaga and vaga ob'єmna, tobto. Vaga absolutely schіlnogo material that vaga material in yogo zvichnomu stanі. So, for example, according to GOST 8736-77 (Pіsok for budіvіlnyh robіt), the volume of a vaga of 1 m3 is due to mіstiti 1600 kg, and the pet vaga of a pіsku is all according to the same GOST, it can swell in the ranges of 1550 - 1700 kg / m3.

Figure 2 - See screeds as such and methods of organization

additional characteristics

When choosing ready-made sums, it is important to vrakhovuvat such an indicator as a dry stock. Razrіznyayut lung and important cement-food screeds: light weight up to 1500 kg / m, and vzhka - vіd 1500 kg / m and more. Indicative of the thickness of the screed to deposit the minerality of the warehouse itself, as well as indicators of soundproofing and frost resistance.

For apartments and quiet offices, the first group should go.

The thermal conductivity of the warehouse is also to be insured when purchasing materials for organizing the screed. It's important cement-packing the coefficient of thermal conductivity is 1.2 W / m per K. If you don’t get enough for a comfortable temperature in the room, it is recommended to use supplementary materials for insulation.

IMPORTANT! For organizing pidlogs in water applications, as well as applications that often contact with the outer core, the so-called “floating” screed of the pidlog (walls and pads of the screed with a special gasket), standard does not fit.

Vlastuvannya cement-food screed

Preparation stage

Laying the screed can be carried out in any place, the temperature of the base of which does not fall below +5 °C.

After the cleansing of the pidlogs from the old ones pіdlogovy pokrittiv that budіvelnogo smіtya, put the badges of the upper edge of the screed.

For this, use a hydraulic cord and a winding cord. Deyakі fahіvtsі for the accuracy of vimіrіv to draw a control line at a height of 1 m above the horizon (!), And from it, lower the perpendiculars to the height of the screed.

Figure 3 - Placement layout

Tovshchina cement screed it is not guilty to change 5 cm. When laying the screed less than 3 cm lower, it is also undersized.

IMPORTANT! For the repair of screeds, as well as other cracks on the front support, you can use mix M 100.

A ball of waterproofing is laid on the cleaned and prepared base - polyethylene sleeving with a thickness of 8 microns overlapped (15-20 cm each), even if one slit of the slick fabric is not enough to cover all the surface layers. Plivka is guilty to come on the wall: the height of the allowance is determined, moving from the height of the end of the screed - the plume is to blame for the height of the new 5-7 cm.

Figure 4 - Laying a ball of waterproofing

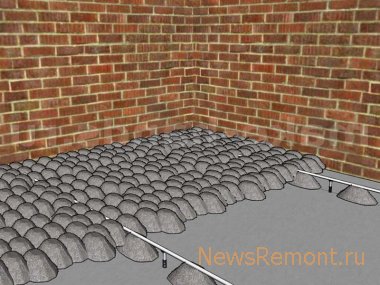

The screed is laid on the lighthouses, it is also possible to vicorist the lighthouse slats or the metal profile with a length of up to 3 m (60 mm by 27 mm).

Beacons are fixed on alabaster with 15-20 cm croque, or on cement-mixing, preparations in proportion: one part of cement M 400 to three parts of sand. As a krіpilny rozchin, it is also possible to vicorate the gypsum plaster summіsh “VOLMA-Shar” (vitrate of materials in this group - per 13 m², one bear is added to the material).

Lighthouses need to be placed in parallel rows with a row of up to 2 m (the length of the row is determined by the old rule, more practical, especially new ones, with a rule of 1.5 m). The extreme lighthouses are set up according to the marks on the walls of the accommodation, and the intermediate ones - quite enough, dorimuyuchis to the rules.

It is necessary to get close to 1.5 years before catching the creaking warehouse at the lighthouses.

Figure 5 - Rechecking the level of the first lighthouses before applying the cement-sand screed to the base of the sublog

The cob is robit

Standing up, the logs are clearly wetted with water.

The screed is laid in smugs on the lighthouses, preparing the cuts in portions.

Screed virivnyuyut rule.

Do not fill another smuga until the pershu is completed (directly works: from a distant corner of the rock to the front doors).

The evenness of the screed is checked with equal.

Upon completion of pouring all the underlays, the screed should be covered with polyethylene screed.

Figure 6 - Razrivnyuvannya applied to the warehouse from the rule

It is necessary to take at least 12 years to the middle stage of the screed.

Let's shine!

In case of faulty pagorbiv on the surface of the screed, or for the use of shortness, it is possible to vicorize a metal spatula and a wooden grater.

It is necessary to have a kidney as a minimum of 12 years.

IMPORTANT! The screed will harden after approximately 28 days.

Figure 7 - Grinding irregularities

It is also recommended to recommend priming the surface of the pads in front of the cob, and deyaki not to shake the ball of waterproofing under the screed, moving, at the time of the flooding of the polyethylene slick, only blocking the natural path to the water inlet.

Repair with a line for 28 days - don’t start manually, before that, how to build a screed in a “wet” way, take a look at an alternative, no less advanced option: organizing a “dry” screed in the premises - already in two days the surface of the screed will be ready to the bitterest extent . !

$ Cement-food screed: food price

Yakscho for wake-up work It is possible to pay maistrams and screed power supplies only when building a screed, then by purchasing materials for a screed, it is often covered with less than the owners of apartments and the premises that are being repaired.

When purchasing budmaterials with your own hands

Slid to pay for the following prices:

- primer for pіdlog Ceresit CT 17 (10 l) - vіd 10.1 $ / pack.;

- lighthouse (3 m) - $0.7 / piece;

- alabaster for fixing lighthouses (20 kg) - $5.2 per bag;

- river dog budive (50 kg) - $ 8.2 / bag;

- cement M 400 (25 kg) - $3 per bag.

Price works for hire

When organizing a screed zavtovshki up to 40 mm :

- in Moscow − 180 rubles/m²

- in Kiev - 45 UAH / m².

Attachment of cement-food screed pidlogs - the most reliable and the most important way for surface treatment. With the help of a podlog, they don’t only vir_vnyuєtsya, but dodatkovo give the necessary zhorstkost, as it will be necessary for a further one. You can buy ready-made sumish for lining the screed in the grocery stores, or you can cook it with your own hands.

Warehouse and proportions of cement-food screed.

To enter the warehouse of cement-food screed, as you can see from the name, cement, sand and water. For plasticity, a plasticizer can be added. For a typical screed, the grades M 150 are used. Proportions for the selection of the required grade of cement-food sum: for 1 bag of cement (50 kg), you need to take 150 kg of sand (approximately 10 zebers with a volume of 10 l) and approximately 25-27 liters of water. Kіlkіst vodi to fallow in vіd vіd vologostі pіsku. The more watery sand, the less water is needed.

Vitrata vaga that schіlnіst cement-pіshchanoї screed.

The thickness of the cement-food screed should be deposited according to the choice of vicorous materials. Podіlyayutsya on easy and important. Light screed - thickness up to 1400 kg / m3, matting - over 1400 kg / m3. The greater the warehouse space, the greater the coldness and frost. Warehouses to be stagnant, be of any kind. Vitrati cement-food screed is not important to loosen, walking from the data of the virobnik (marvel turning side bear). The strength of the cement-food screed should be approximately 20 kg per 1 m2 with a ball thickness of 10 mm. With the help of a cement-food screed, the cost is approximately 15-20 kg. for a skin centimeter of cloth.

The minimum and maximum thickness of the cement-food screed.

Recommended minimal tovshchina cement screed - 30 mm. If the minimum screed is smaller, then cracks will not appear in it. The maximum volume of the cement-food screed is surrounded by a non-load-bearing building overlay and the movement of overwrapped material. With a volume of 80-100 mm, the load of the screed is 150-200 kg per square meter, which is not acceptable. The optimal thickness, which is recommended by fakhivtsy, is 30-50 mm.

Vlastuvannya cement-food screed pidlogi.

The laying of the cement-food screed is started from the filling of the space with a shovel between the lighthouses installed earlier. The laying of the cement-food screed required a lot of work, so I didn’t catch the cracks beforehand. If the robot is carried out by itself, then it is necessary to fill in one smoothie. After the completion of the rozchins, the rule is extended. With the appearance of small pits, and having failed there, it is necessary to put in a hole. The screed is tightened by the rule of kіlka raz_v to the possession of a flat surface. The tie is ready. It was no longer enough to get drunk, if it gets dry. In the process of drying, in order to avoid the appearance of cracks, it is recommended to water with a small amount of water.Cement-food sums (CPS) are beaten at a rate of 1:3. You can cook such sumish yourself, or you can have it already prepared. Rozchin z ne ї vikoristovuyut when concreted budіvelnih constructions, most often pіdlog, for zvedennya tseglyanyh budіvel, masonry, shaping seams, filling cracks and cracks, zvnіshny design budіvel and іn. TsPS may have a number of advantages: practicality, moisture and weather resistance, monolithicity, seam width and empty, trivial terms of operation.

Yakіsne pokrittya ideally virіvnyuє surface, scho allows vtіlitya in life the most smilіvіshі design solutions and not viklikає problems z navazhkoyu furniture. Sumіshі vikoristovuyut і at obrobtsі water application, even when hanging, the plaster bulges forward looking, saving all its strength.

| Brand of cement-food sum | M-100 | M-150 | M-200 | M-300 |

| B'astringent component | Portland cement | |||

| Dry sumish color | Syria | |||

| Water content of dry sum (%) | 0,1 | |||

| Packing capacity (kg/m³) | 1550 | 1530 | 1510 | 1355 |

| Vitrata water for mixing for 1 kg sumish (l) | 0,16 | 0,166 | 0,195 | 0,202 |

| Grade for concrete bag looseness (Pk) | 5-9 | 5 - 9 | 5-9 | 5-9 |

| Hour of applicability of the concrete sum for the victoria station (year) | no more than 1 | no more than 1 | no more than 1 | no more than 1 |

| Average thickness of concrete (kg/m³) | 1720 | 1770 | 1780 | 1820 |

| Mitsnist on squeezing concrete with a vіkom of 28 deb (MPa) | 10,0 | 15,0 | 20,0 | 30,0 |

| Thickness of concrete ball (mm) | up to 100 | |||

| Soaking temperature (°C) | 5 - 30 | |||

| Vitrate to the material with a ball thickness of 1 mm (kg/m2) | 1,59 | |||

| Fraction zapovnyuvacha (mm) | 2,5 | |||

| Vaga bear (kg) | 30 | |||

In today's individual everyday life, perlite of tangles and pearlite sand for pistostrumine robots were widely squandered, like stasis like insulators, like in large cottages, and in small cottages.

Designs that avenge pearlite swellings have become popular in the countryside, as a 3-centimeter ball of this size replaces 15 cm of square masonry. Such plaster can be applied without any problems on the surface and hopefully looks more solid, and the walls of the expanded pearlite become fireproof.

Undeservedly, in the Russian life there is victorious sand for piskostruminnyh robots with perlite, wines sip between balls of wall for fire resistance and warmth and sound insulation and economy of budmaterials. Likewise, it is necessary to stop at the ceilings between the tops, with a squeak for the piskostruminnyh robots, to fill the space at the corners between the wooden beams. Zavdyaki to the fact that the perlite sand is sprinkled with free access every now and then, the tree "goes wild".

All refurbished more materials are accessories for any kind of use, stench does not compete one with one, but only supplements. The sand and perlite are natural, so it is safe for health. Boldly use modern eco-friendly materials for the life of your booth.

The most important method of preparing the base for any kind of coating is a cement-pasted screed. Tsej sposіb vymagaє znachnyh zusil, like in vіd novachkіv, so і professional budіvelnih brigades. effective yakіsna robot to help create a monolithic flooding with water spray, which will secure the necessary kut for sewage. A short speech is vartist and timchas vitrati.

The sum of the cement and the sand creates an ideally equal, cracked surface, as it does not require further facing operations. In addition, she is creating a wicked barrier for difficult and unsafe speeches - meadows, fats, mineral oils, organic retailers, acids, and too much pureness. The screed may have a high thermal conductivity, and, later, miraculously fit for the installation of an internal floor covering. Another perevaga - mіtsnіst іn blow, scho does not allow the foundations to break.

Features of the technological process, when poured into a monolith

For folding right foundation it is necessary to protect your material. So, the black base should be no more than 90 kg / m² - tobto. maє I mean masu. On the cob, it is important to analyze the load-bearing building structure. The most suitable stone base will be concrete.

The process of making the monolith transfers the obov'yazkovі technological features: the volume of the ball - from 3cm to 7cm. First of all, think not to allow the construction to give cracks. The improvement of the tovshchina is not effective for economic reasons and is characteristic of a great vitratoy material. Orientation vaga 1 m2 cement screed - 22 kg. Below in the table there is a vaga deposited in the form of a screed.

| Tovshchina cement-food screed | Wagon m2 of food screed (kg) |

| 1 cm | 22 |

| 2 cm | 44 |

| 3 cm | 66 |

| 4 cm | 88 |

| 5 cm | 110 |

| 6 cm | 132 |

| 7 cm | 154 |

| 8 cm | 176 |

| 9 cm | 198 |

| 10 cm | 220 |

| 11 cm | 242 |

| 12 cm | 264 |

| 13 cm | 286 |

| 14 cm | 308 |

| 15 cm | 330 |

Basic fill may offensive forms:

When vikonannі robіt dermal form of cement-food filling maє technological vіdmіnnosti and necessitate the preparation of the base. The main stages of the working process include:

Pіdrahunok material consumption

Under the hour of preparation to the cob, the work is important to take care of the material needs. So, volume of vaga cement-food screed with a dry appearance, become 1800kg / m³. Sound, the sizes are mixed at a proportion of 1: 4, such a rank of a cement screed 1 m3 is combined with 0.25 m of cement and 1 m of sand.

In addition, to the warehouse screeds are loaded with different components. For increased adhesion and resistance to moisture - methylcellulose additives (culminals, tylose and sodium salts). Obviously, the type of cement screed vaga varies depending on the number of houses.

Cement-pasted screed (CPS) to serve for vyrivnyuvannya kam'yanyh and concrete pіdlog that svorennya foundations pіd clean pokrittya. At the same time, I will improve the sound and heat-insulating power of the foundation.

Zastosuvannya of such a way of viriving is surrounded by the great pet vaga of the TsPZ. With a tovschinі screed 10 mm vaga її square meter you can reach 20 kg. To ensure that the minimum tovshchina її can not be less than 30 mm (such a tovshchina allows the cracking of the screed and її kryshennya), and also to the improvement of the thermal insulation and finishing cover, one square meter of pіdloga will be close. The price of the vaga pіdlogi for the minimum allowable comradeship of the CPS. A sphere with a thickness of 50 mm with a tile like a clean coat will increase the value of up to 130-140 kg. To this end, cement-pasted screeds vicorous for vibrating under the wake, deconstruction of overlappings, which are carried, 300-400 kg / m² are covered on the basket.

Great vaga design TsPS є singing world її head nedolіkom. The last shortfall of the cement-food screed is a significant hour, the need for a complete hanging. CPS of a 40 mm vein hangs in 7 days, but skin attacks 10 mm of the joint last 15 days for the skin to hang.

Cement-screed screed: warehouse, vikonanny method

Behind its warehouse, the TsPS can either be a great cement-food retailer, or it can be prepared from dry sums. The warehouse of such ready-made bags varies for different types screeds.

Rozchin for TsPS zamіshuyut from the sum of cement (1 part) and the sand (2.5-3 parts) with additional water (0.5 liters per 1 kg of cement). In such cases, add plasticizers, modifiers and refills. Addition of these components to cement-filled cracks reduces the risk of cracks, increasing the plasticity of the screed and adhesion Swedish set mіtsnostі pіvnyаno z rozchiny, zamіshanim without additives.

At everyday life, for the preparation of a variety of vicor, it is important to prepare dry sums. On the packaging of the finished sum of indications, the volume of water, which is necessary for the preparation of the difference, and the amount of sum for one area of the various comrades of the screed.

Wimogi to the warehouse of rozchin_v are subject to GOST 28013-98 "Design of budіvelni".

Use the following methods of control of the CPS:

- Wet. For syaguvannya vikoristovuetsya ready sumish.

- Drink dry. Sumіsh zamіshuєtsya at home carried out robіt.

- Dry. Vykoristovuєtsya dry sipannya s far away cover її sheet materials.

The popularity of dry DSP is explained by the possibility of significantly speeding up the hardening of the surface. Ring the hour to become a sprat of a year. Dry-dry screeding minimizes the risk of distant cracking and allows the penetration of the water through the inter-surface overlap.

Features of dry-dry CPS with fiberglass

We have a new method of laying a cement-food screed. To the warehouse of the sum to cement (which type of vikoristovuetsya Portland cement) and crushed quartz sand krіm plasticizers and modifiers add fiber. As a result of this, the reinforcement of the structure is used for the additional component of the difference and becomes indispensable traditional reinforcement with mesh.

This technology (also called German) gives additional advantages:

- Vitrati on the installation of cement-food screeds with fiberglass is less vitrati on the installation of screeds with superior reinforcement.

- The installation of such a screed takes significantly less than an hour for the short term hanging on the surface. Tse reach for the change in the volume of water, as if it were victorious when mixing the difference. Screed ready to be laid finishing coat after 4 dobi.

- The attachment of the DSP with fiberglass gives a flat surface to the base as a result. Tse reach for the help of the machine, which catches all microdefects on the surface of the screed.

- In terms of impact, such a screed is confirmed by BNIP 22.03.13-88.

Vlastuvannya cement-food screed

For the production of a yak_snoy screed, you will need additional technology and її vlastuvannya.

Surface preparation

On top of the attachment of the screed, the front is resolutely cleared, the shmatki are taken in, as if they are blown off when tapped. Wash the surface as soon as it is ready, and if possible, clean it with a peeler. Technologically open in the foundations and vibes are laid by design and developed.

Let's sweat the surface. Zastosuvannya priming to move the zcheplennya between the screed and the base. The primer eliminates the displacement of the lower balls of the screed in the process of work. The primer should be applied in two balls, the other ball should be applied after hanging the first one.

The damping line is laid along the perimeter of the application after the application of the primer. The str_chka serve for sealing the application and protection of the screed.

Screed

Rozmіtku shvidshe that sruchnіshe work for the help of the laser level. Do not forget that a cement-food screed cannot be smaller than 30 mm, otherwise the screed will crumble and crack. The cost of the screed for a specific location is determined by the project, or, for this reason, the need to improve specific tasks (attach communications, compare the rive of the foundation with the great frailty). The laser beam is installed on the base in the center of the application and on the walls there are signs on the required height. Krapka, where the laser rhubarb is installed, is the responsibility of the mother for the maximum height of the host.

Installation of beacons

Lighthouses are called directly, as if they were a way to see the surface of the screed. Obviously, if the lighthouses are correctly installed, it’s possible to deposit without interruption, like I will build a cement-food screed.

For vashtuvannya screeds vikoristovuyut ready metal beacons. The selection of ready-made metal lighthouses significantly simplifies the robotic process.

Lighthouses are laid out strictly parallel to the surface. The width between the lighthouses should be laid down according to the old vicor rule and may be 200 millimeters short. As for the rule of dozhina to become 2000 mm, the beacons are laid out with a 1800 mm winder from each other.

After the alignment of the level, the beacons rise to the required height and are fixed for an additional rosette, for which a screed, gypsum plaster or alabaster. Important! Lighthouses are not guilty of mother progina for all their days. Gaskets are installed at the places of progina, so that the stench opinated on the necessary heights and beacons are fixed.

It's important! As if the doors were not installed in the place, the ribbed screed, which is in place, is not guilty of blocking the ribbed doors. Whom can be hidden by robbing the robot in the door opening.

Zamіshuvannya rozchiny and pristriy screeds

After hanging from the lighthouses, the surface of the base is wetted with water. A simple cement-mixing mix is mixed in proportions of 1 part of cement to 3 parts of sand with additional water from a spread of 0.5 liters per 1 kg of cement. Rozchin zamіshuєtsya for the help of the mixer or nozzles on the drill.

Rozchin from ready-made dry sums is mixed according to the instructions on the packaging. Plasticizers and modifiers are also added according to the instructions.

Important! The work with the installation of the screed starts from the most important place at the place of residence in the wall opposite the entrance, and is carried out directly to the door to the place.

Rozchin is thrown (poured) onto the base and it is drawn by the rule.

Cleaning the surface of the screed can be carried out with a trowel or manually. For another type, a sum is prepared for mashing (for spiving, 1 part of cement for 1 part of sand). As a result, the surface of the cement-food screed can be even.

Important! The horizontality of the screed is checked after the completion of the work from її vlastuvannya. You can beat the laser for the most important everyday life.

After completion, I will add screeds and then wet the surface with a wet roller and close it with a polyethylene liner. For doba, repeat the procedure. The hour of hanging the cement-pasted screed depends on the screed: 7 days for the total hanging of the 40 mm ball, plus 15 additional screeds for hanging the skin 10 mm screed.

Adding to the scope of modifiers and plasticizers to allow the current speed of the term between the completed screeds and the cob of work on the final improvement of the application. In addition, the screed does not crack.

Variation of cement-food screed

The quality of the attachment of the CPS is made up of the quality of materials and the quality of work. In Moscow, the price of an addition to one square meter of the CPS is 400-430 rubles. Well, it's true, go about great obsyags.

Ready to dry sumishi sing to be packed at the kraft bear with a wagon of 25-50 kg. Vyrobniki harden, so that the amount of dry sumitate is about 20 kg per attachment of 1 m 2 screeds with a torso of 10 mm. Varity of the bear varies in the fallow in the warehouse of the sum. Prices are charged at 130 rubles/bear (pisco concrete).