See the electrical installations of luggage wires

At the statue, one can see the nourishment of the supremacy of the two and more guides for additional twisting, solderings of that terminal connection. Proponuyutsya variants of the choice of these methods for the superior connection of two and more darts to various electrical appliances.

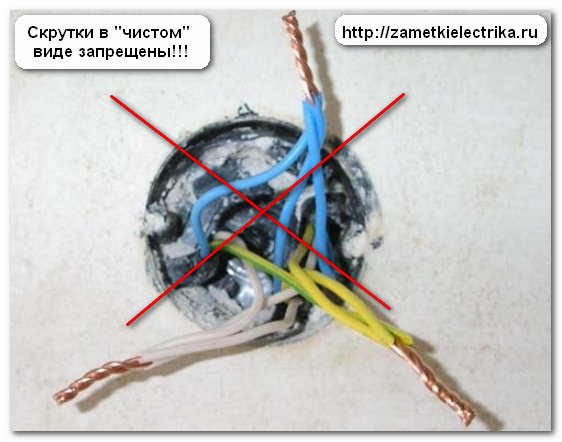

Dart twist

The simplest way to join two and more conductors is the so-called twisting. Dane z'ednannya vykonuetsya for the help of different techniques, with some intuitively sensible and simple twisting.

Z'ednannya two buggy trunk wires at a simple parallel twisting secures the top contact between the two wires, but with this twisting it's bad to transfer the vibration and apply to the opening of the susilla.

For the help of parallel twisting, it is possible to connect the middle monolithic and luggage wires, the wires to the additional twist of the monolithic wire are given above, lower when two luggage wires are connected.

A similar method is used to mount aluminum darts of a cut cut.

Zastosuvannya parallel twisting gives the possibility to secure electrical contact at the same time between two and more wires.

For the help of simple twisting, an electrical connection of an additional wire with the main line of electrical wiring can be connected without opening. For whom, in the required area, insulation is required, after which, for the help of simple twisting, the connection of an additional conductor is connected.

This method of connection can be twisted to connect at the same time from a monolithic wire with a flexible or monolithic main wire.

To connect two wires at once, you can twist them afterward, for which the leather wire, which is wound, “winds” on the other.

![]()

The given method of connection of wires allows to ensure optimal contact and reliability of the connection, albeit for two wires.

Z'ednannya zhorstnyh wires between themselves can be vikonuvatysya for help twisting. For this purpose, they are wired, they are applied in parallel one to one, after which they are fixed in this position for the help of a larger soft dart, which is firmly placed on the bare surface of the wires.

The more twisted or winding will be, the sooner there will be electrical contact between conductors.

For an additional bandage, you can get two more conductors or more waterways.

To improve the fixation, you can fix the additional screw of the monolithic dart, and fix the bandage yourself.

Under the hour of installation, it is necessary to have stitches, so that parts of the conductors, which are twisted, will be completely cleaned and insulated, the middle or aluminum surface of the conductors must be clean and not tainted by oxidation. As a matter of necessity, before twisting the surface of the wires that are connected, it is necessary to clean them with an additional knife or an emery paper. To increase the width of twisting, and, as a last resort, electrical contact between conductors, it is allowed to twist with additional pliers. It is important to remember the smut rule for installation - it is not possible to cut through copper and aluminum electrical wiring without intermediary.

Spike darts

For the help of a special solder and an electric soldering iron, you can secure more reliable connections between all types of copper electrical wiring. Covering the middling dart with a thin ball of lead-tin solder (ludinnya) allows you to protect it from oxidation under a splash of high water.

In the fall, in the warehouse and melting temperature, the following main types of solder are distinguished:

- PIS 15 - 280 °C.

- PIS 25 - 260 °C.

- PIS 33 - 247 °C.

- PIS 40 - 235 °C.

- PIS 60 - 191 °C.

- PIS 61 - 183 °C

- PIS 90 - 220 °C.

For the purpose of the leather conductor, go through the moon for additional rosin (flux) and solder:

- The conductor is cleaned from insulation and possible oxidation.

- Soldering with a soldering iron is heated to the melting point of rosin and zanuryuetsya at it.

- Solder solder is melted on the tip of the soldering iron.

- With smooth hands, the air of the conductor of solder is transferred to the middle conductor.

After the moon, the guides join each other for the help of one of the descriptions of earlier different twists. Before tightening the wires at the twist from their surface, behind the help of the knife, excess flux is seen, which did not evaporate. Shards of hardness of tinned dart are a significant thing, equal to the work, which did not pass, the twist is “pulled up” for the help of pliers. For superficial electrical and mechanical wiring, further heating of the twist with a soldering iron to the fusion temperature of the tinned surface of the conductors is required. For a superficial zadnannya, you may need additional application of solder in the area of twisting tinned darts.

Shards can be good to conduct heat in the soldering iron, a strong overheating of the conductor can cause melting of the insulation, to minimize this negative factor, the choice of the most optimal temperature for the melting temperature of the solder and the heating of the conductor will be short.

Terminal blocks, options for connecting electrical wiring

Today, a large number of different terminal blocks have been broken up, which allow you to reliably fix the rods and guarantee a good electrical contact. Strumoprovidna the surface of the terminal blocks vibrate from brass or other materials, if they do not interact with the middle, or with aluminium, that can be beaten to organize the transition of middling-aluminum.

Most terminals can be divided into two types.

1. Squeezy. At this terminal block, the fixation of the dart is fixed for the help of a built-in spring.

2. Gvintovy. Here the fixation of the dart is victorious for the help of the gwent.

In our case, in order to increase the area of the contact, the wires from the jet-conducting surface are made of brass, copper and aluminum wires are additionally bent.

When vikoristannyh screw terminals, it is important to remember that the mid and aluminum arcs are soft materials, and the zausilla, when the terminal is tightened, can bring the yak to the “zrivu” of the cutting, and to the crushing of the dart.

If necessary, the terminal block can be replaced with a metal bolt from a small number of washers and a nut.

A steel or brass washer is laid between the skin conductor for a superficial connection of a rich-core or monolithic copper core with aluminum cores. The passages are cleared in front and folded over with a “kіlts”. The laying of the wires on the bolt is carried out in such a way that when the nut is tightened, the "ring" is not unraveled. The bolt for electrical wiring can be cleaned, not rusted, for work it is best to use galvanized bolts and made of stainless steel.

For a one-hour connection to more than one terminal, it is recommended to recommend a distant link for additional help, looking ahead to seeing parallel twisting.

Such an installation allows optimizing the electrical contact and preventing the trash from squeezing the wires.

Electrical insulation

All parts of the electrical wiring are due to be insulated, so that the fluffy dot of the parts of the strum-conducting elements between themselves and the human body can be insulated. The choice of insulating materials should be deposited in the minds of the operation of the electric stake. For more fluctuations, there is sufficient insulation from a thermal or vinyl tube, as well as a special insulating line.

As a place of sewing, it can be injected with high temperatures, for insulation, varnished fabric and fabric insulating stitching are used, which shows the effect of temperatures up to 100 ° C.

Exploitation of electrical wiring to lie down due to various factors, in the middle of which there are no remaining places to borrow correctly and electrical installation. Necessarily connected wires and correctly connected elements electric lines allow you to avoid faults with bad contacts and, as a result, local overheating and shaving of electrical wiring.

Vikoristany method of z'єdnannya provіdіv znachnoyu іroy to lay іnіt іn іt thе maximum demand іt thе minds ekspluatatsії ї elektroprovoda. In watery places and on the streets of the varto, you can see the difference between the middle wires and the soldered floors, the shards are less sensitive to oxidation.

Vlad Taranenko, rmnt.ru